Dimethyl ether prepared from marsh gas and preparing method for the same

A technology of dimethyl ether and biogas, which is applied in the field of producing dimethyl ether fuel from biogas, can solve the problems of waste, low output, and biogas processing, and achieve the effects of promoting production and development, broad market prospects and protecting the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

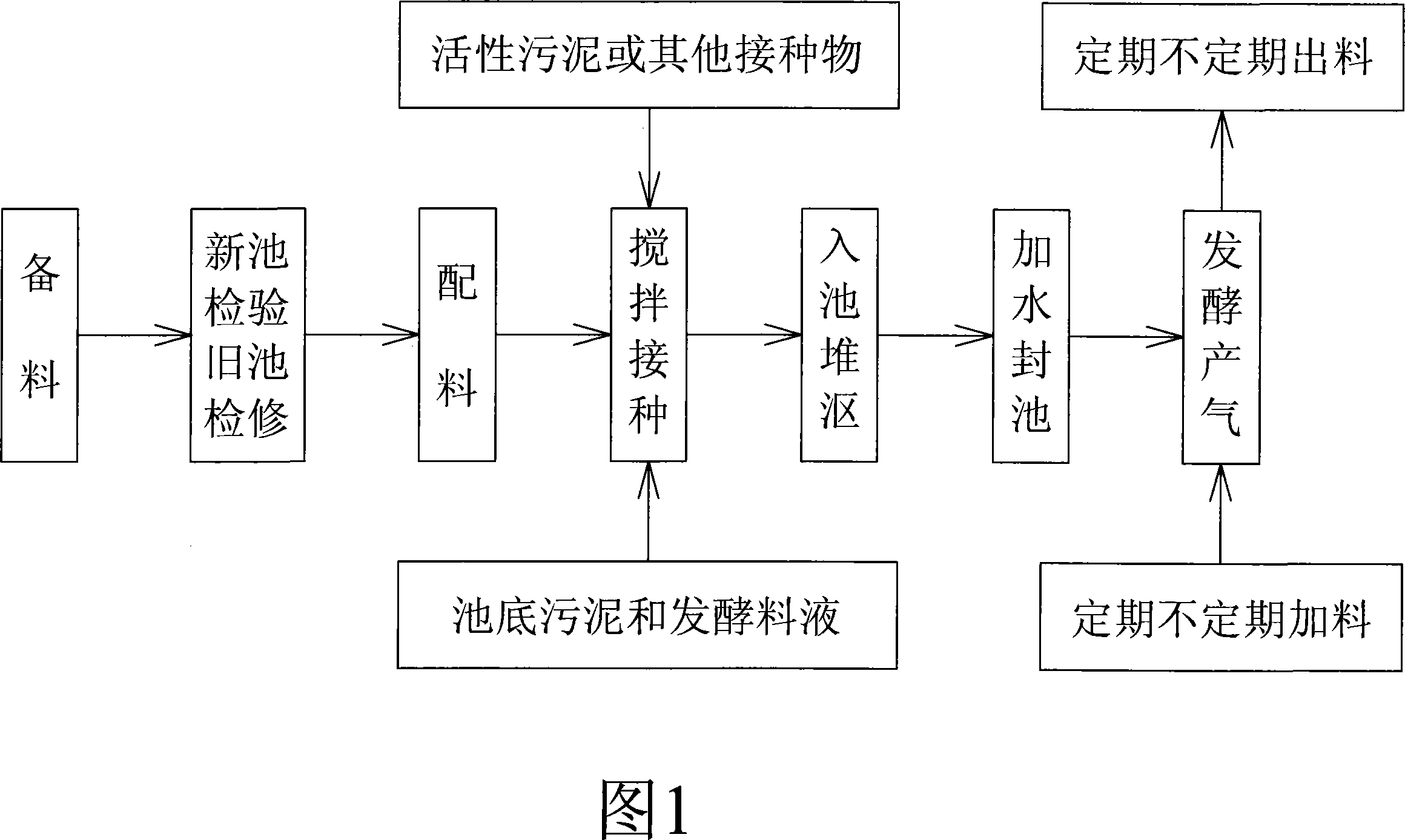

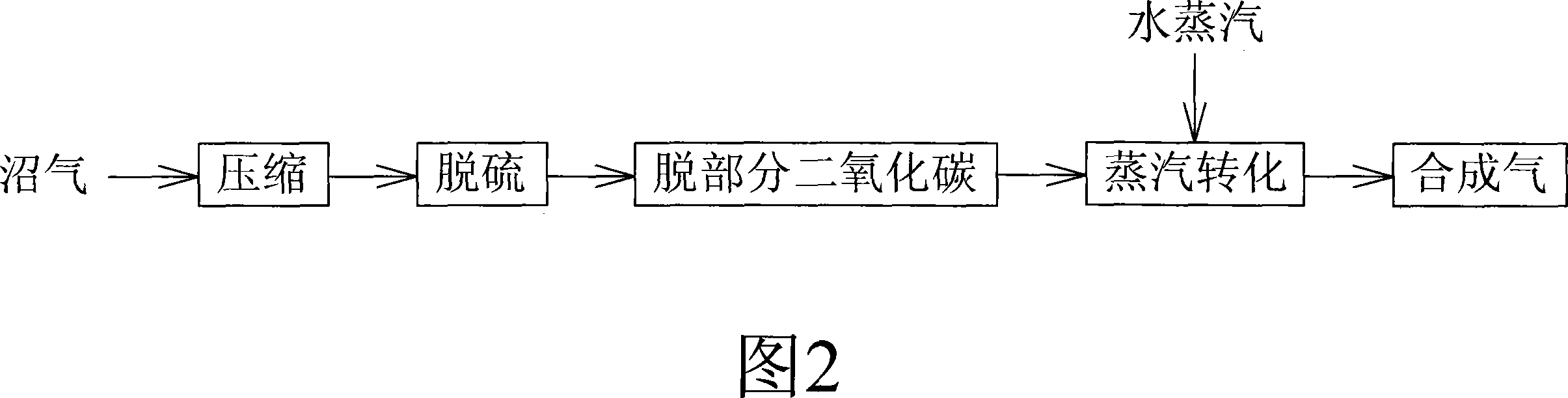

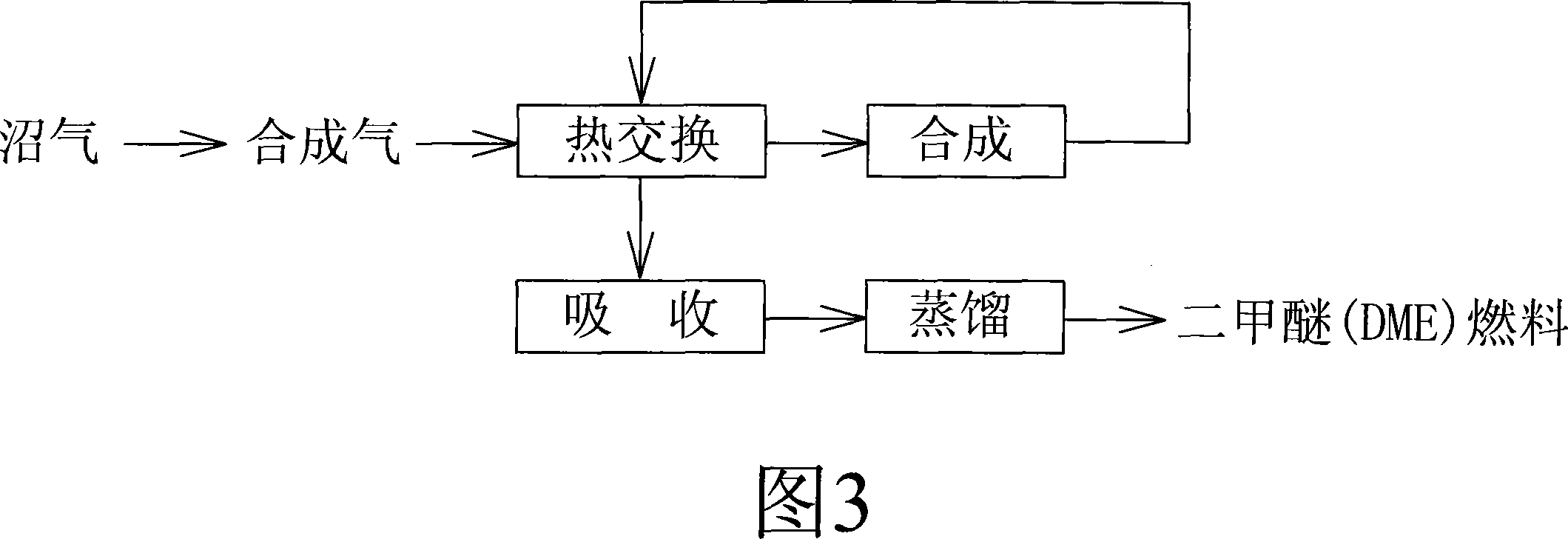

[0013] Using biogas to produce dimethyl ether fuel is to compress a certain amount of biogas to 3.0-3.6Mpa through a compressor, then use a known wet desulfurization process for rough desulfurization, and then use a known dry desulfurization process for fine desulfurization. Desulfurization up to sulfur content less than 10 -8 , using the known ammonia water decarbonation process to remove part of the carbon dioxide in the biogas so that the carbon dioxide content remaining in the biogas accounts for 6-20% of the total volume, through a known tubular steam reformer, through water steam and on a nickel-based catalyst Under the action of conversion, the catalyst uses Ni / Al 2 o 3 , it is known that the tube wall temperature of the reformer is controlled at 700-920°C, the temperature of the gas medium is 680-820°C, the operating pressure of the reformer is 1.6-4.0Mpa, the water-carbon ratio is 3.5, and the gas flow rate is 500-3000h -1 , converted to H 2 , CO and CO 2 of synth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com