Measuring method for temperature of supercritical once-through boiler membrane wall

A membrane-type water-cooled wall and once-through boiler technology, which is applied to thermometers, measuring devices, and heat measurement, to achieve the effects of reducing operating costs, prolonging service life, and avoiding pipe bursts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

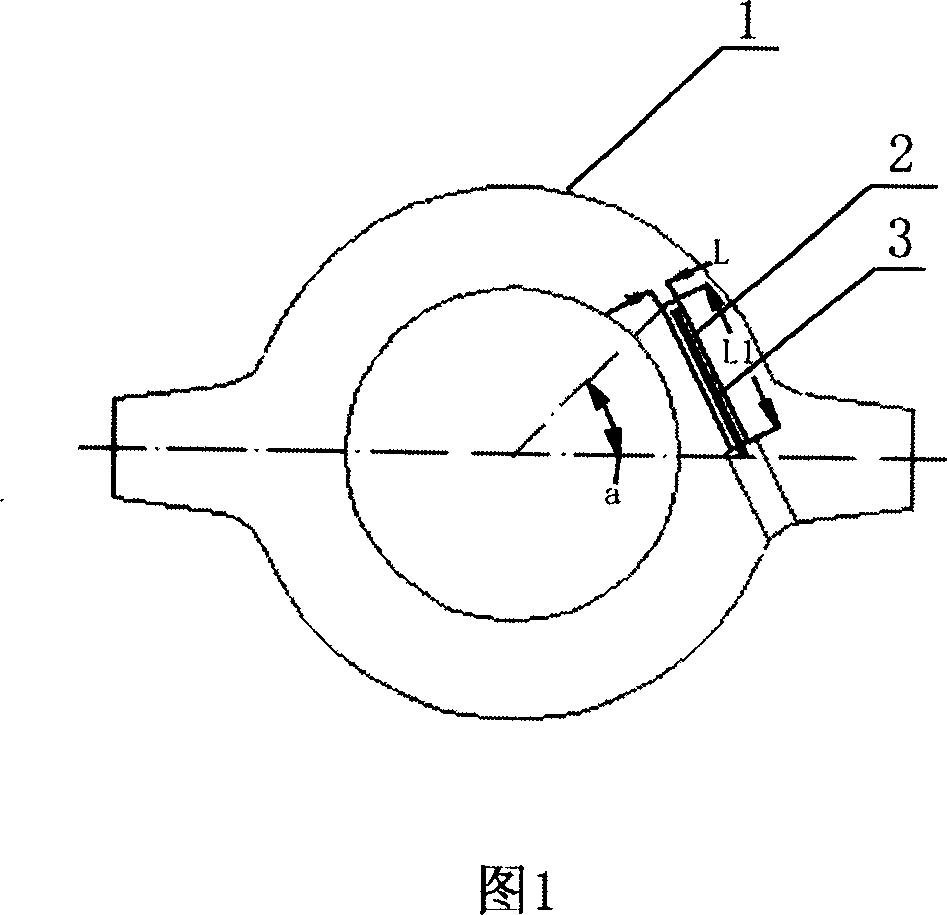

[0020] As shown in accompanying drawing 1, the present invention is a kind of measuring method of membrane type water wall temperature of supercritical once-through boiler, and this method is as follows: 1. measure and calculate the stress of the water wall tube that will measure temperature, according to the result obtained in water cooling Select the opening point on the wall tube; ② Open a hole with a diameter of φ1.1mm and an outer edge of φ2mm on the water-cooled wall tube that has measured the opening point; ③ Insert a temperature measuring thermocouple with a diameter of φ1mm in the opened hole , Measure the wall temperature of the water-cooled wall tube to the fire side through the temperature measuring thermocouple. In the figure, L=1.1, L1=9.5, a=45.

[0021] The above-mentioned measurement methods are as follows: ①Using the finite element method to compare the stress calculation of the water-cooled wall to be measured with the hole and without opening the hole to se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap