Non-aqueous solvent, non-aqueous electrolyte compositions, and non-aqueous electrolyte secondary battery

A non-aqueous solvent and composition technology, which is applied in the field of lithium ion non-aqueous electrolyte secondary batteries, can solve the problems of deterioration of battery performance and reduction of discharge capacity retention ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

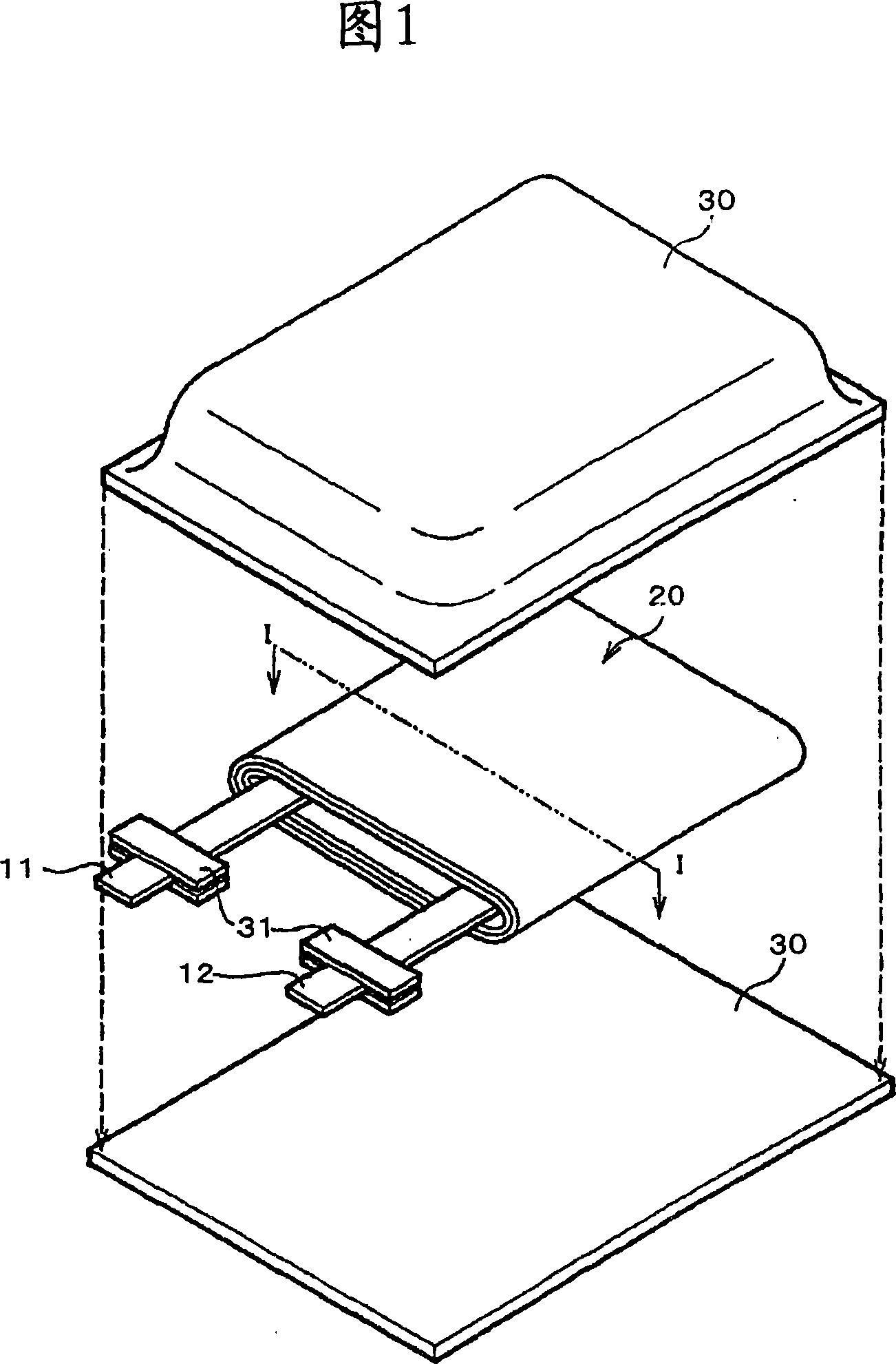

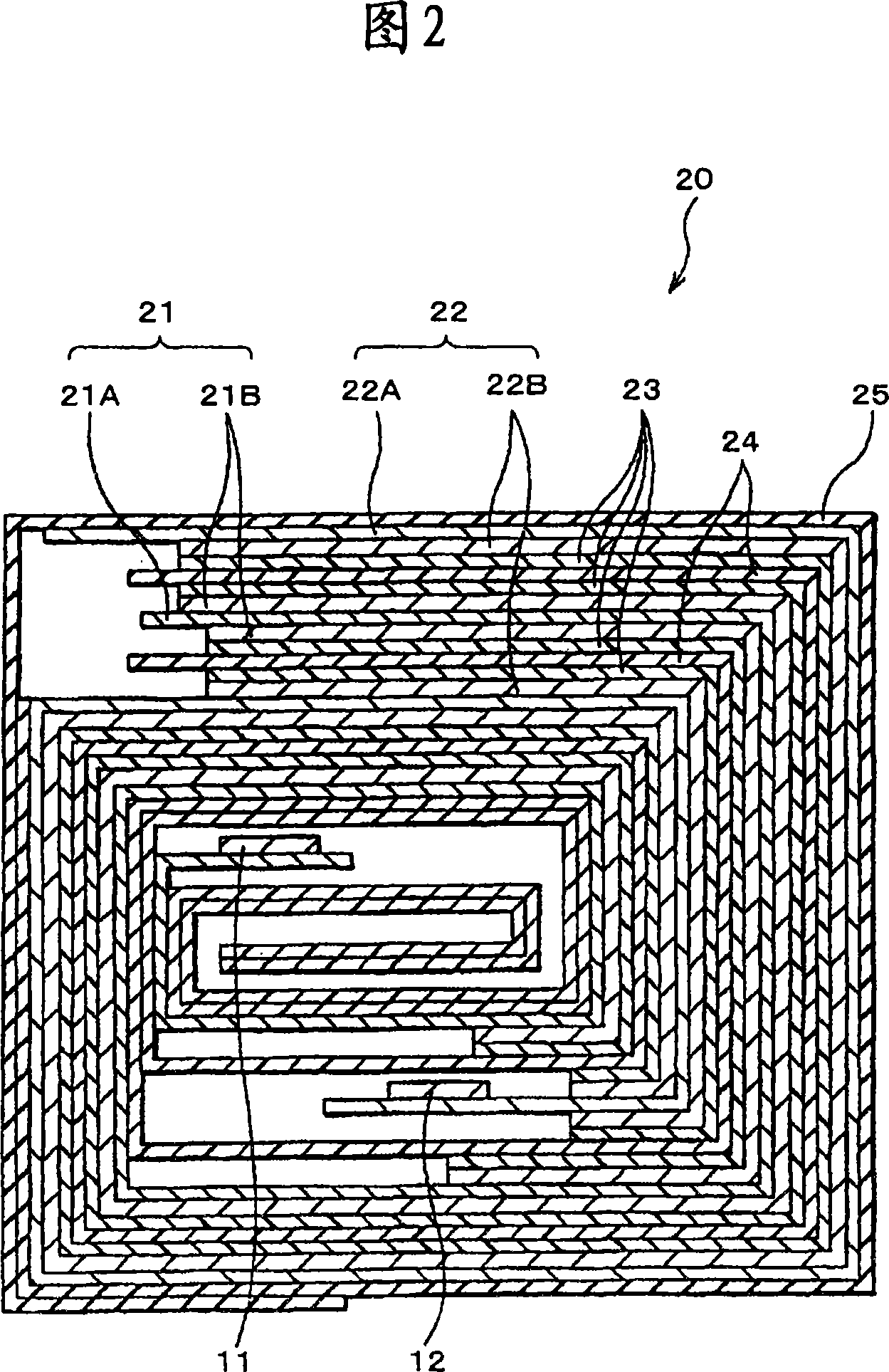

[0098] First, 94 parts by weight of lithium cobalt composite oxide (LiCoO 2 ), 3 parts by weight of graphite as a conductive material and 3 parts by weight of polyvinylidene fluoride (PVdF) as a binder are mixed uniformly and N-methylpyrrolidone is added to obtain a cathode mixture coating solution.

[0099] Subsequently, both surfaces of the aluminum foil with a thickness of 20 μm were uniformly coated with the obtained cathode mixture coating solution, and the cathode mixture coating solution was dried to obtain 40 mg / cm per surface. 2 The cathode mixture layer. The cathode mixture layer was cut into a shape having a width of 50 mm and a length of 300 mm, thereby forming a cathode. Further connect the cathode terminal.

[0100] Subsequently, 97 parts by weight of graphite as an anode active material and 3 parts by weight of PVdF as a binder were uniformly mixed and N-methylpyrrolidone was added, thereby obtaining an anode mixture coating solution. After that, both surfaces of a ...

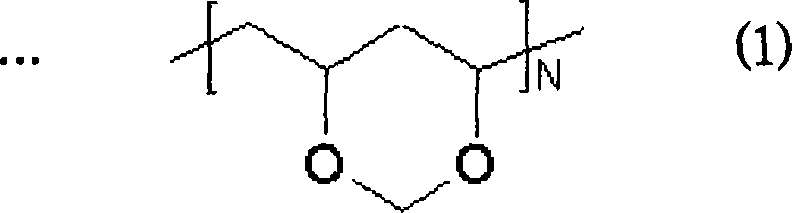

Embodiment 2 to 31

[0106] Repeat the operation similar to Example 1, except that the mixing ratio of ethylene carbonate, propylene carbonate and diethyl carbonate and the addition amount of vinylene carbonate are limited in the ratio shown in Table 1, thereby obtaining Examples 2 to 31 laminated battery. The change in discharge capacity was measured in a similar way as described above, and the results obtained are shown in Table 1.

[0107] From Table 1, it can be seen that the use of a non-aqueous electrolyte composition containing ethylene carbonate, propylene carbonate, and diethyl carbonate in a predetermined range ratio and a non-aqueous electrolyte composition using a predetermined range of vinylene carbonate is used in comparison with each group therein. The discharge / charge capacity retention ratio after 100 cycles is improved compared with the comparative example in which the content of the components is not within the predetermined range.

Embodiment 32-41

[0109] Repeat the operation similar to Example 1, except that the mixing ratio of ethylene carbonate, propylene carbonate and diethyl carbonate and the addition amount of vinyl ethylene carbonate (VEC) are defined in the ratio shown in Table 1, so as to obtain The laminated batteries of Examples 32-41. The change in discharge capacity was measured in a similar manner as described above, and the results obtained are shown in Table 1.

[0110] It can be seen from Table 1 that by using a non-aqueous solvent containing ethylene carbonate, propylene carbonate, and diethyl carbonate in a predetermined ratio range, and using a non-aqueous electrolysis method to add vinyl ethylene carbonate in a predetermined range Compared with the comparative example in which the content of each component is not within the predetermined range of the liquid composition, the charge / discharge capacity retention ratio after the completion of 100 cycles is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com