Process method of sterilization, enzyme inhibitor for non-thermal fruit and vegetable concentrated juice

A processing method and technology for concentrated juice, which are applied in the field of non-thermal fruit and vegetable concentrated juice sterilization and enzyme-inhibiting processing, can solve the problems of quality decline, fruit juice quality decline, unfavorable flavor, etc., to improve the concentration, reduce the transportation cost, and overcome the ineffectiveness of the enzyme effect. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

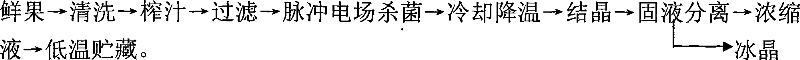

Image

Examples

specific Embodiment approach

[0008] (1) The specific implementation method is as follows: firstly process the fruits and vegetables through processes such as crushing, squeezing, filtering, and extracting juice to obtain fresh fruit and vegetable juices, and then process them according to the following steps:

[0009] ① At room temperature, let the fruit and vegetable juice flow through a high-voltage pulsed electric field with an electric field strength ≥ 10kv / cm, a pulse number ≥ 10, and a pulse width ≥ 2μs and ≤ 100μs for sterilization. The pulse processing time is equal to the product of the pulse width and the number of pulses, the higher the pulse electric field strength, the shorter the pulse processing time; under the same pulse processing time, the larger the pulse width, the fewer the pulse number, and vice versa. The pulse electric field intensity, pulse width and pulse number can be adjusted according to different fruit and vegetable juices. For example, the pH value of orange juice is low, so ...

Embodiment 1

[0015] Example 1: Non-thermal orange juice

[0016] (1) Choose fresh oranges, wash them, drain them, cut them in half, squeeze the juice, filter, and get the clear juice.

[0017] (2) Pass the above-mentioned clear juice through a high-voltage pulsed electric field with an electric field strength of 10 kv / cm, a pulse number of 400, and a pulse width of 17 μs for sterilization to obtain cold sterilized orange juice. (If the electric field strength is 20kv / cm, only 140 pulses are required.)

[0018] (3) The cold-sterilized orange juice with an initial concentration of 13°Brix is freeze-concentrated at -1.5°C to -4.7°C, and then becomes a frozen-concentrated orange juice with a concentration of 34°Brix. The product is stored at -10℃~-18℃.

Embodiment 2

[0019] Example 2: Non-thermal carrot juice

[0020] (1) Choose fresh carrots, wash and drain, peel, beat, filter, and get clear juice

[0021] (2) The above-mentioned clear juice is passed through a high-voltage pulsed electric field with an electric field strength of 20 kv / cm, a pulse number of 400, and a pulse width of 17 μs for sterilization to obtain cold-sterilized carrot juice.

[0022] (3) The cold-sterilized carrots with an initial concentration of 7°Brix were freeze-concentrated at -3°C to -6°C to obtain frozen-concentrated carrot juice with a concentration of 33°Brix. The product is stored at -10℃~-18℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com