Super-high density vertical magnetic recording medium and method for making same

A technology of perpendicular magnetic recording and magnetic recording media, which is applied in the field of information storage, can solve the problems of low efficiency in commercial mass production, unfavorable operations by ordinary technicians, and harsh preparation conditions, and achieve good industrial production prospects, simple equipment, and crystal grains. small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

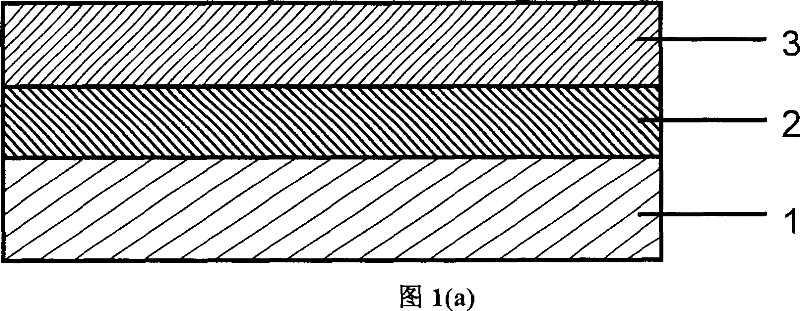

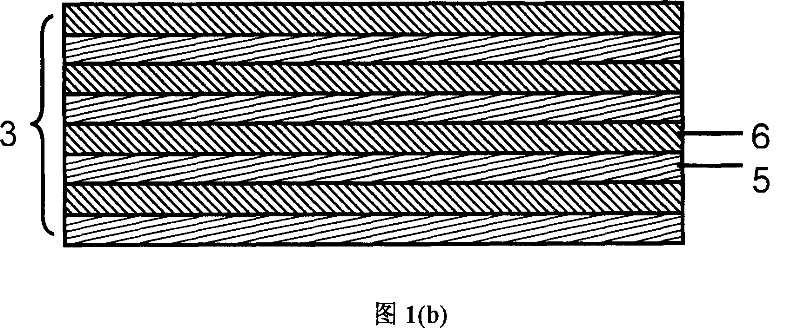

[0029] Embodiment 1: prepare [CoPt (3nm) / C (3nm)] 5 / Ag (10nm) / the multilayer film magnetic recording medium of glass substrate

[0030] Follow these steps:

[0031] (1) Ultrasonic cleaning the 0.1cm thick glass substrate with electronic cleaning solution, distilled water and alcohol to remove oil stains and other impurity ions on the surface of the substrate, then put the cleaned substrate into the sputtering chamber, and install A CoPt composite target, an Ag target, and a non-magnetic material C target, wherein the CoPt atomic ratio in the CoPt composite target is 1:1.

[0032] (2) Pump the sputtering chamber, when the background vacuum of the sputtering chamber is better than 2×10 -4 Pa, pass through the working gas Ar gas to keep the working pressure between 5Pa and 6Pa. After starting each working target position to make it glow normally, select the appropriate sputtering power of each target to pre-sputter the target for several minutes to clean the target surface. The...

Embodiment 2

[0039] Embodiment 2: prepare [CoPt (3nm) / BN (2.5nm)] 5 / Ag (10nm) / the multilayer film magnetic recording medium of glass substrate

[0040] Adopt the same step as Example 1, first deposit the Ag bottom layer of 10nm on the glass substrate, then get the CoPt layer of 3nm to the CoPt target sputtering 11s, then to the BN target (the BN target sputtering power is 150W, and the target base distance is 6cm, the sputtering rate is 0.0487nm / s) to obtain a 2.5nm BN layer by sputtering for 51s, taking sputtering a layer of CoPt / BN as a cycle, and repeating sputtering for five cycles without changing the sputtering time, the structure can be obtained as [ CoPt (3nm) / BN (2.5nm)] 5 / Ag (10nm) / glass substrate multilayer film, described each layer thickness all is the value before vacuum sputtering sample or annealing. After the sample is annealed, the multilayer magnetic recording medium of [CoPt(3nm) / BN(2.5nm)]5 / Ag(10nm) / glass substrate of this embodiment can be obtained.

Embodiment 3

[0041] Embodiment 3: prepare [CoPt (3nm) / C (3nm)] 5 / Ag (0,5,10,30,50nm) / the multilayer film magnetic recording medium of glass substrate

[0042] According to the steps described in Example 1, where the Ag target sputtering time changes to 0s, 20s, 40s, 120s and 200s, a series of films with different thicknesses of the Ag bottom layer can be prepared respectively, and a series of [CoPt (3nm) Magnetic recording medium of / C(3nm)]5 / Ag(0, 5, 10, 30, 50nm) / glass substrate.

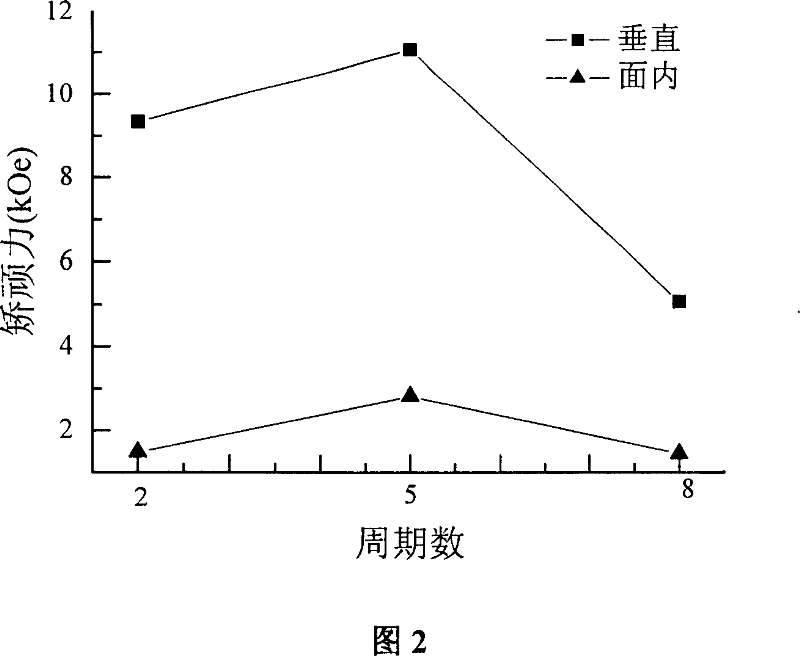

[0043] The thin film structure of present embodiment series has been characterized by X-ray diffractometer, because the intensity ratio I of CoPt (001) peak and (111) peak 001 / I 111 can be described as L1 0 - Figure of Merit for the degree of ordering of CoPt, Table 1 lists the L1 for different Ag layer thicknesses 0 -CoPt perpendicular magnetic recording media in X-ray diffraction I 001 / I 111 The value of and the grain size calculated according to the Scherrer formula, where CoPt (15nm) / substrate is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com