Preparation and purification method of hydrogen selenide

A purification method and technology of hydrogen selenide, applied in the direction of binary selenium/tellurium compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

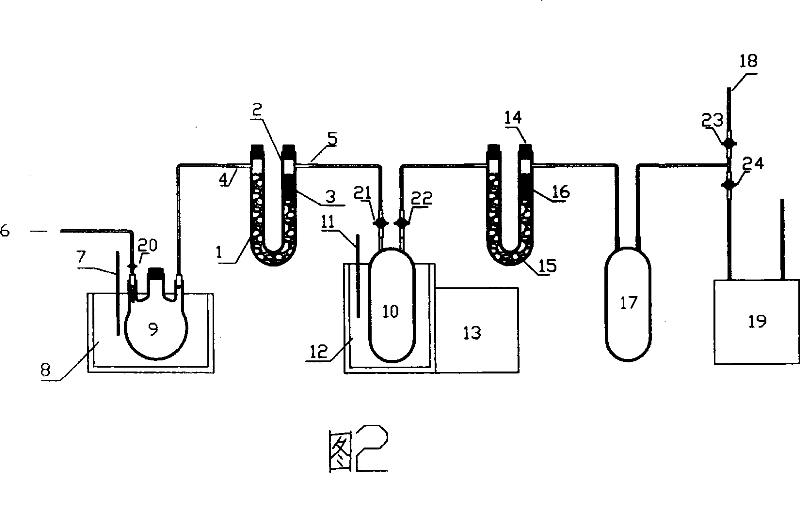

[0013] A kind of example of the preparation purification method of hydrogen selenide of the present invention, the flow process of its process is as follows:

[0014] (Al 2 Se 3 +H 2 O)→wet H 2 Se gas → (0°C) to remove H 2 O → use Al 2 Se 3 Adsorbed H 2 O→(-50℃)H in cylinder 2 Se liquefaction → (-50°C) liquid H 2 Gently evacuate the Se cylinder → close the cylinder valve to complete the operation

[0015] Compare Figure 2:

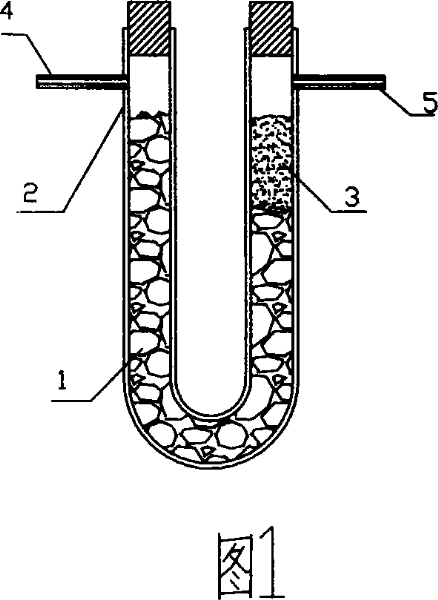

[0016] newborn H 2 The Se gas 6 is passed into the saturated water vapor condenser 9, and a part of the saturated water is condensed and removed under cooling below 0°C in the ice bath 8, and then enters the adsorber 2 through the adsorber inlet 4, and the residual moisture therein is combined with the adsorbent Al 2 Se 3 Particle filler 1 contacts and reacts, H 2 The Se gas is completely dried, and the particles entrained in the gas are filtered out by the chemical fiber filter layer 3 of the adsorber, and then enter the H through the outlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com