Biodisc reactor disc and manufacturing method thereof

A biological turntable and reactor technology, which is applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc. problem, to achieve the effect of high COD removal efficiency, good effect and strong resistance to organic load impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

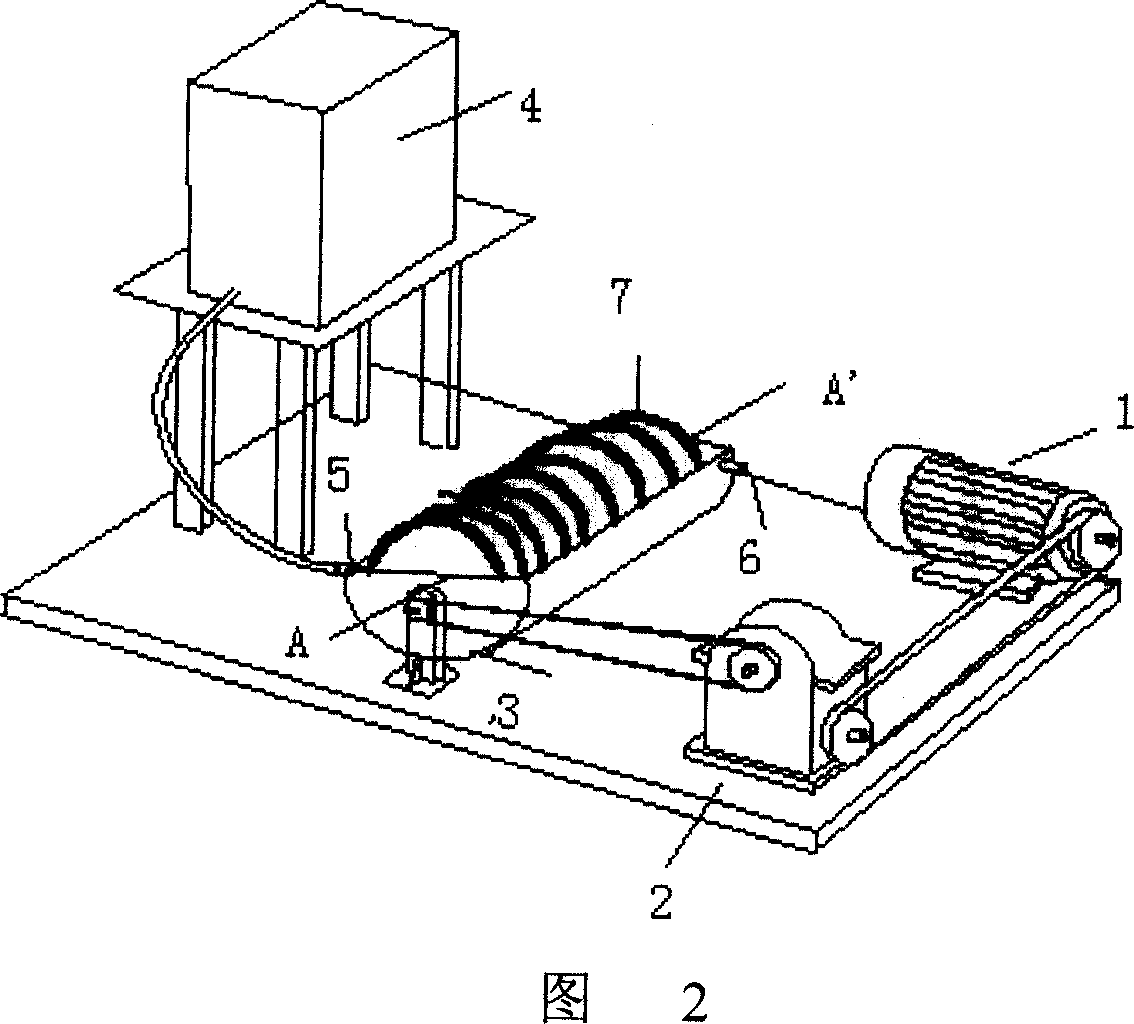

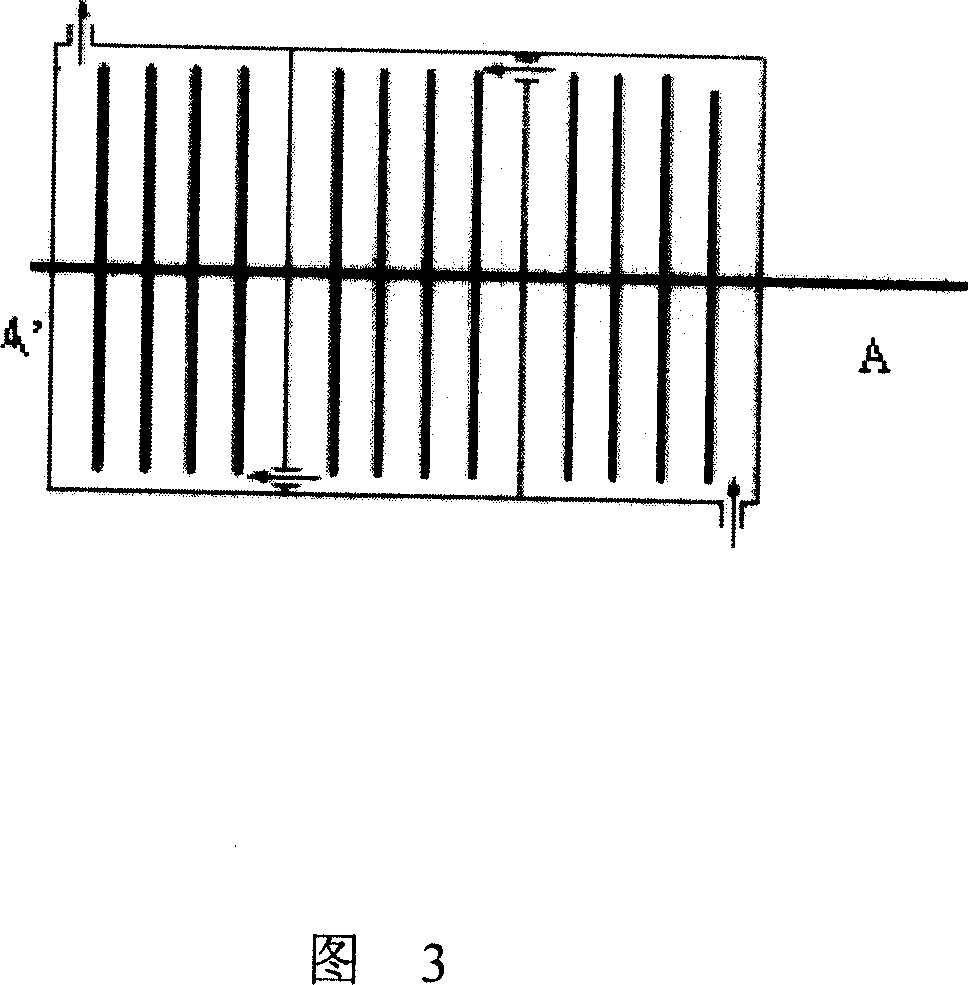

[0023] The present invention will be further described below in conjunction with the accompanying drawings:

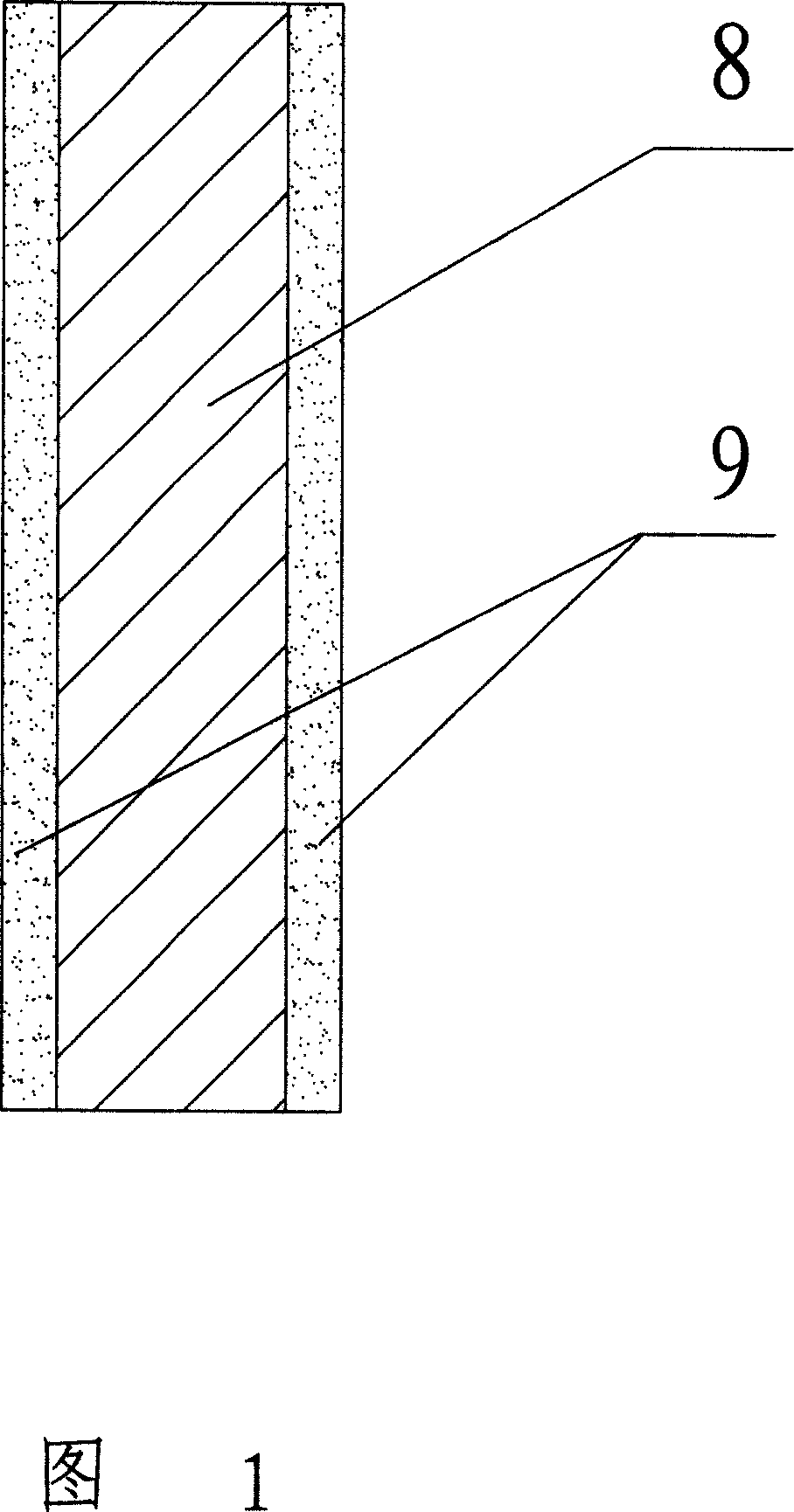

[0024] The conceptual basis of the present invention is first introduced. In order to solve the problems in the prior art that the discs of the biological turntable reactor are not resistant to corrosion, are easily deformed, the surface is not rough enough, the processing efficiency is low, and the service life is short, it is considered that a disc material with corrosion resistance and high processing efficiency should be re-selected. , From this, think of whether activated carbon can be used as a disc material. As common sense, activated carbon has a large specific surface area, light weight and unique adsorption capacity, and is a good biofilm carrier, but due to its own shape limitation, it is usually used as a filter material in water treatment, and cannot be directly used for on the biological turntable. Therefore, if the problem of fixing activated carbon on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com