Method for treating and reclaiming wastewater of polyester piece goods dyeing and finishing

A polyester fabric, dyeing and finishing wastewater technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, flotation water/sewage treatment, etc., can solve the problem of low removal rate, lack, and low recycling rate of dyeing and finishing wastewater and other problems, to achieve the effect of preventing odor and improving the recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

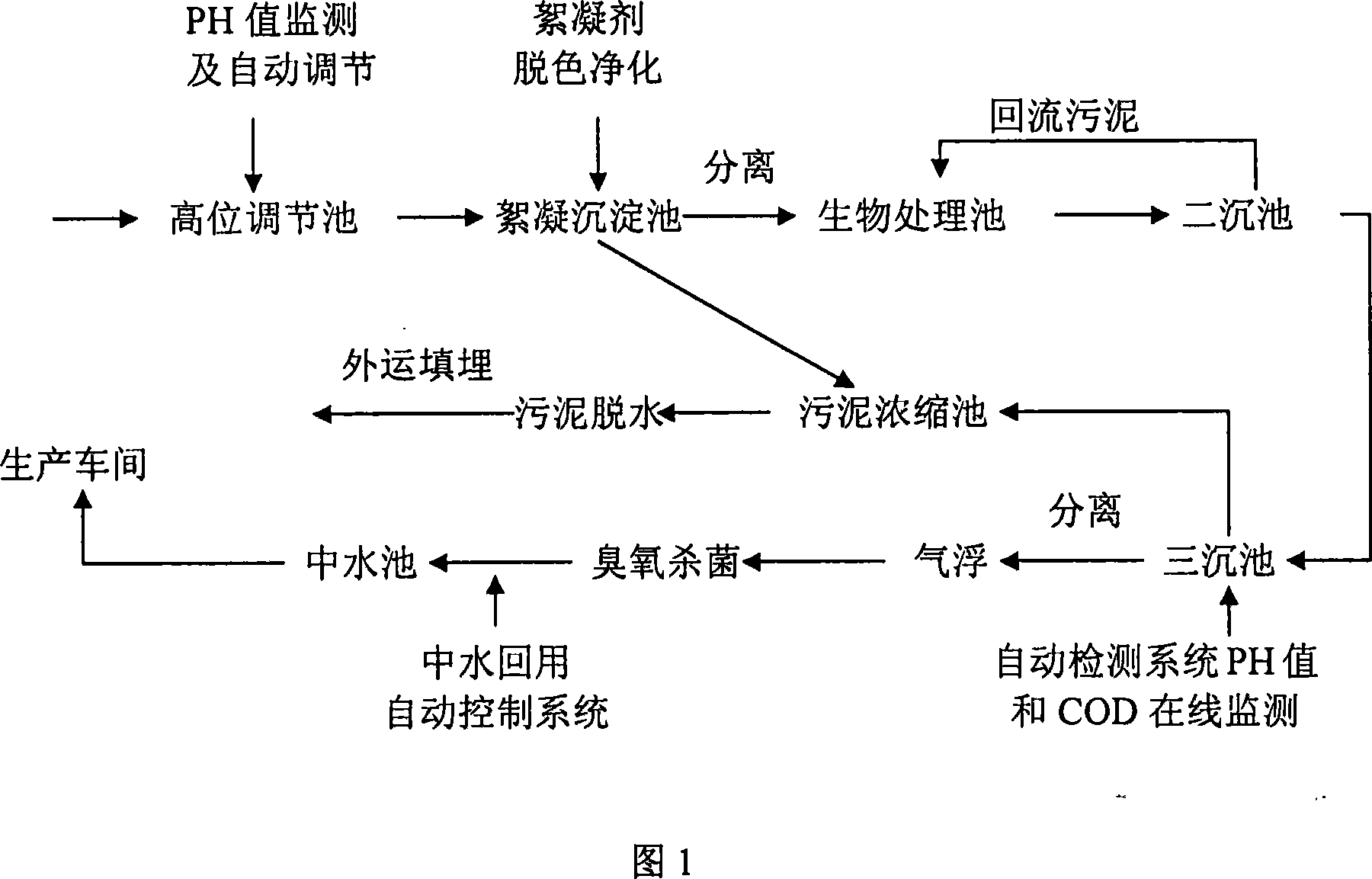

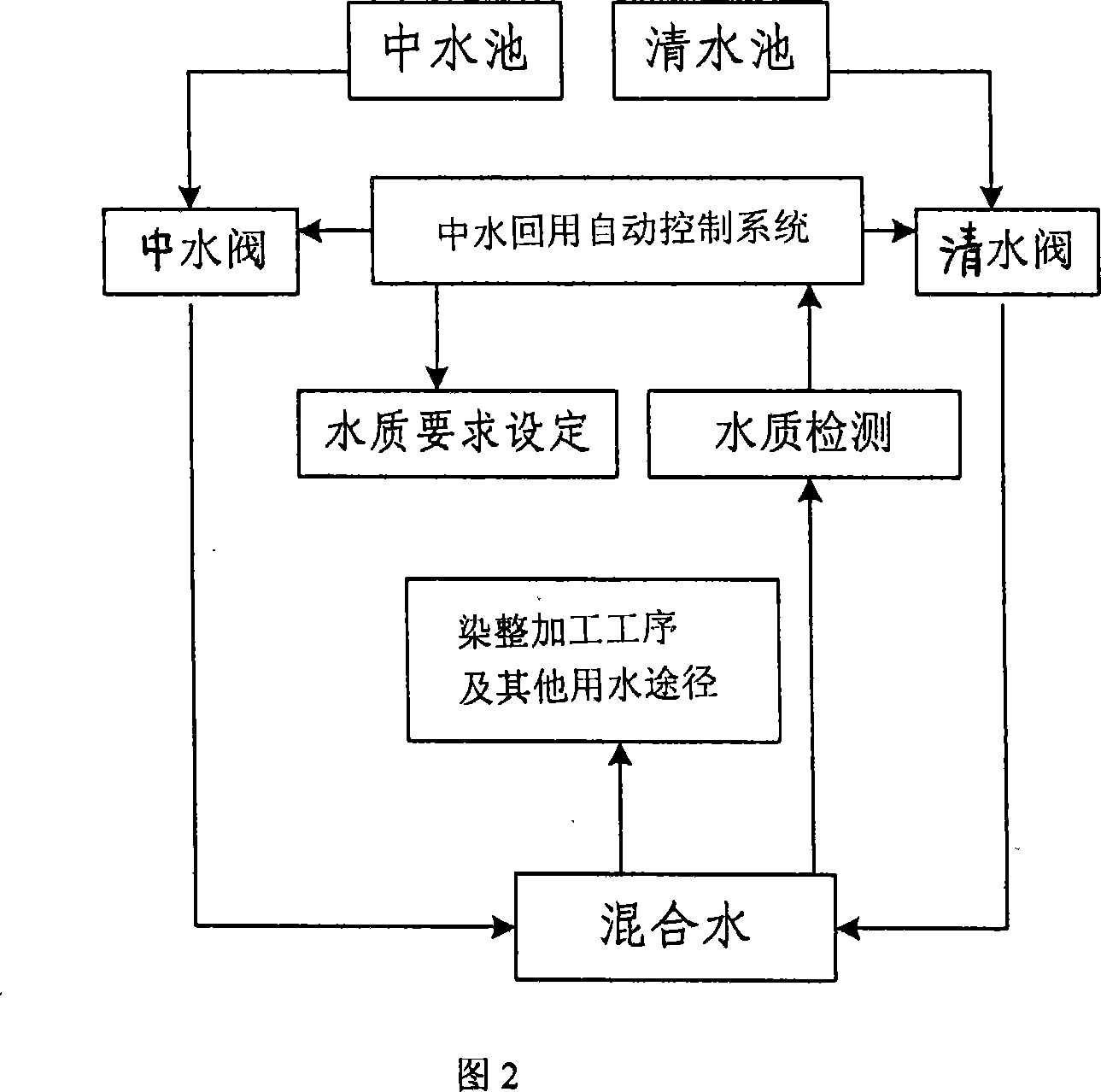

[0025] Referring to Figure 1 and Figure 2, polyester fabric dyeing and finishing wastewater enters the high-level adjustment tank, and the pH value is monitored. 2 CL 3 The reagent adjusts the pH value of dyeing and finishing wastewater to less than or equal to 8. The adjusted dyeing and finishing wastewater enters the flocculation sedimentation tank for decolorization and purification, adding a ternary composite inorganic polymer flocculant: Al(III) / Fe(II) / Mg(II) composite inorganic flocculant 100mg / l, natural polymer composite Flocculant: chitosan and acrylamide graft copolymerized chitosan mixture 50mg / l, ternary composite inorganic polymer flocculant is used to remove disperse dyes in dyeing and finishing wastewater, natural polymer composite flocculant is used to remove dyeing and finishing active substances in wastewater. The dyeing and finishing wastewater after decolorization and purification is separated, the separated sludge enters the sludge concentration tank, an...

Embodiment 2

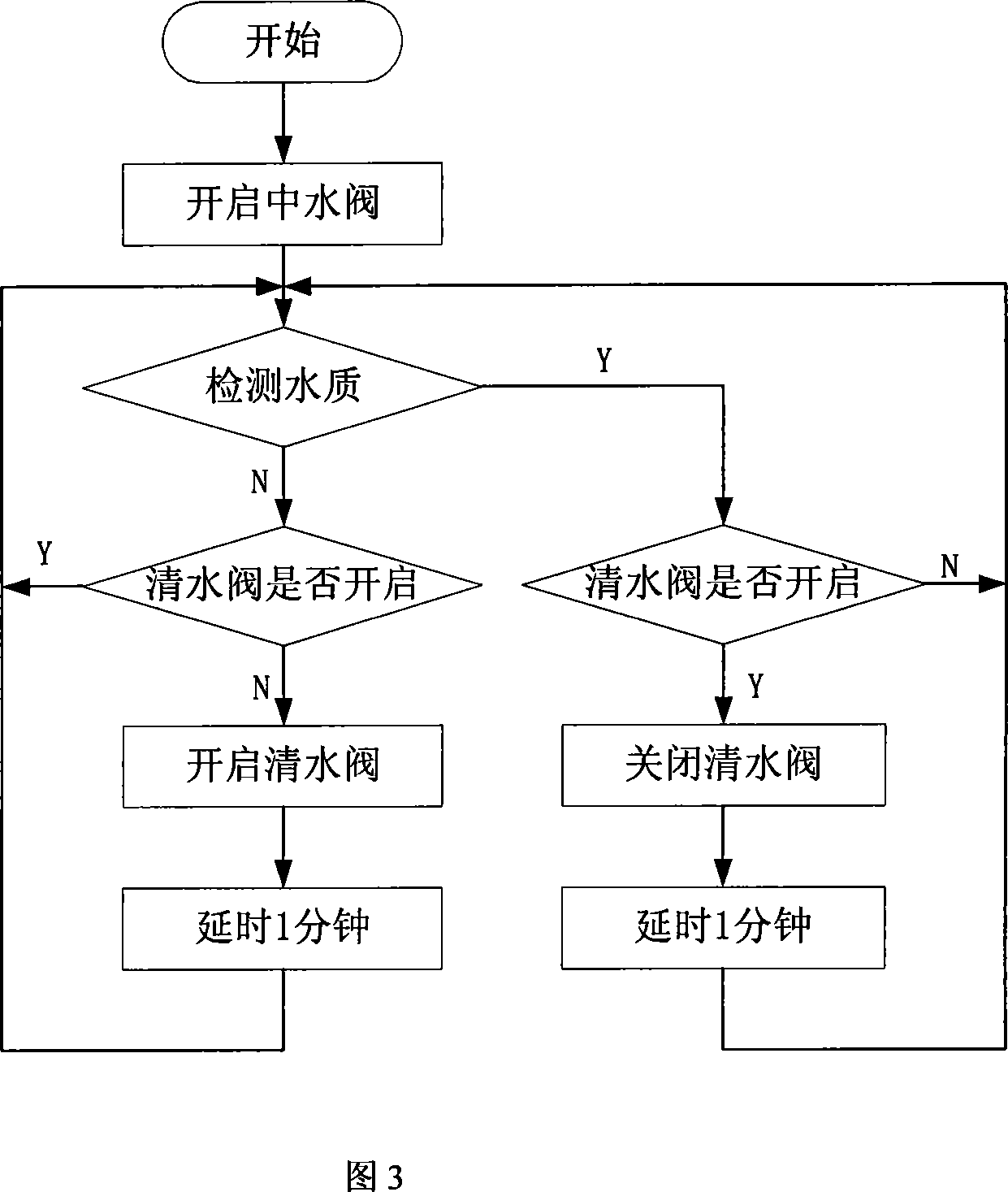

[0027] Referring to Figure 1, Figure 2, and Figure 3, polyester fabric dyeing and finishing wastewater enters the high-level adjustment tank, and the pH value is monitored. 2 CL 3The reagent adjusts the pH value of dyeing and finishing wastewater to less than or equal to 8. The adjusted dyeing and finishing wastewater enters the flocculation sedimentation tank for decolorization and purification, adding a ternary composite inorganic polymer flocculant: Al(III) / Fe(II) / Ca(II) composite inorganic flocculant 120mg / l, natural polymer composite Flocculant: chitosan and dimethyl diallyl ammonium chloride graft copolymerized chitosan mixture 50mg / l, ternary composite inorganic polymer flocculant used to remove disperse dyes in dyeing and finishing wastewater, natural polymer Composite flocculants are used to remove active substances in dyeing and finishing wastewater. The dyeing and finishing wastewater after decolorization and purification is separated, the separated sludge enters ...

Embodiment 3

[0029] Referring to Figure 1, Figure 2, and Figure 3, polyester fabric dyeing and finishing wastewater enters the high-level adjustment tank, and the pH value is monitored. 2 CL 3 The reagent adjusts the pH value of dyeing and finishing wastewater to less than or equal to 8. The adjusted dyeing and finishing wastewater enters the flocculation sedimentation tank for decolorization and purification, adding a ternary composite inorganic polymer flocculant: Al(III) / Mg(II) / Ca(II) composite inorganic flocculant 100mg / l, natural polymer composite Flocculant: chitosan and dihydroxypropyltrimethylammonium chloride chitosan mixture 60mg / l. The ternary composite inorganic polymer flocculant is used to remove disperse dyes in dyeing and finishing wastewater, and the natural polymer composite flocculant is used to remove active substances in dyeing and finishing wastewater. The dyeing and finishing wastewater after decolorization and purification is separated, the separated sludge enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com