Technique for producing extractive of olive growing leaves

A technology of olive leaf extract and production process, which is applied in the field of production process of olive leaf extract, can solve the problems of low content of oleuropein, total phenols and flavonoids, etc., and achieve good product quality, high extraction rate and reasonable process route Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

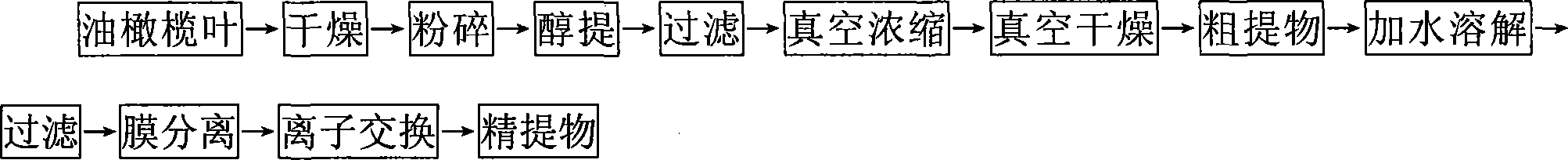

Method used

Image

Examples

Embodiment 1

[0023] Take 100kg of dried olive leaves, crush them, add 10 times of 90% ethanol to reflux extraction, filter the leachate, concentrate in vacuum, and dry in vacuum. The temperature of concentration and drying should not exceed 55°C to obtain 16kg of crude olive leaf extract. The crude extract was pulverized, passed through a 80-mesh sieve, dissolved in water, filtered, separated by membrane, separated and purified by ion exchange, and 1.8 kg of olive leaf extract was obtained.

Embodiment 2

[0025] Take 100kg of dried olive leaves, crush them, add 15 times of 80% methanol to reflux and extract, filter the leachate, concentrate in vacuum, and dry in vacuum. The concentration and drying temperature should not exceed 55°C to obtain 13kg of crude olive leaf extract. The crude extract was pulverized, passed through a 60-mesh sieve, dissolved in water, filtered, separated by membrane, ion-exchanged and alcoholized to obtain 1.5 kg of olive leaf extract.

Embodiment 3

[0027] Take 100kg of dried olive leaves, crush them, add 10 times of 85% ethanol to soak and extract twice, each time for 48 hours, and the extraction temperature is 55°C, combine the extracts, filter, concentrate in vacuum, and dry in vacuum. The temperature of concentration and drying should not exceed 55°C, 19kg of crude olive leaf extract was obtained. The crude extract was pulverized, passed through a 80-mesh sieve, dissolved in water, filtered, separated by membrane, ion-exchanged and alcoholized to obtain 1.8 kg of olive leaf extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com