Melting method of converter, and facility for implementing the method

A converter and equipment technology, applied in non-ferrous metal smelting, ferroalloy production, and ferrous metal fields, can solve the problems of constant frequency value, negligible stirring effect, and not too good effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

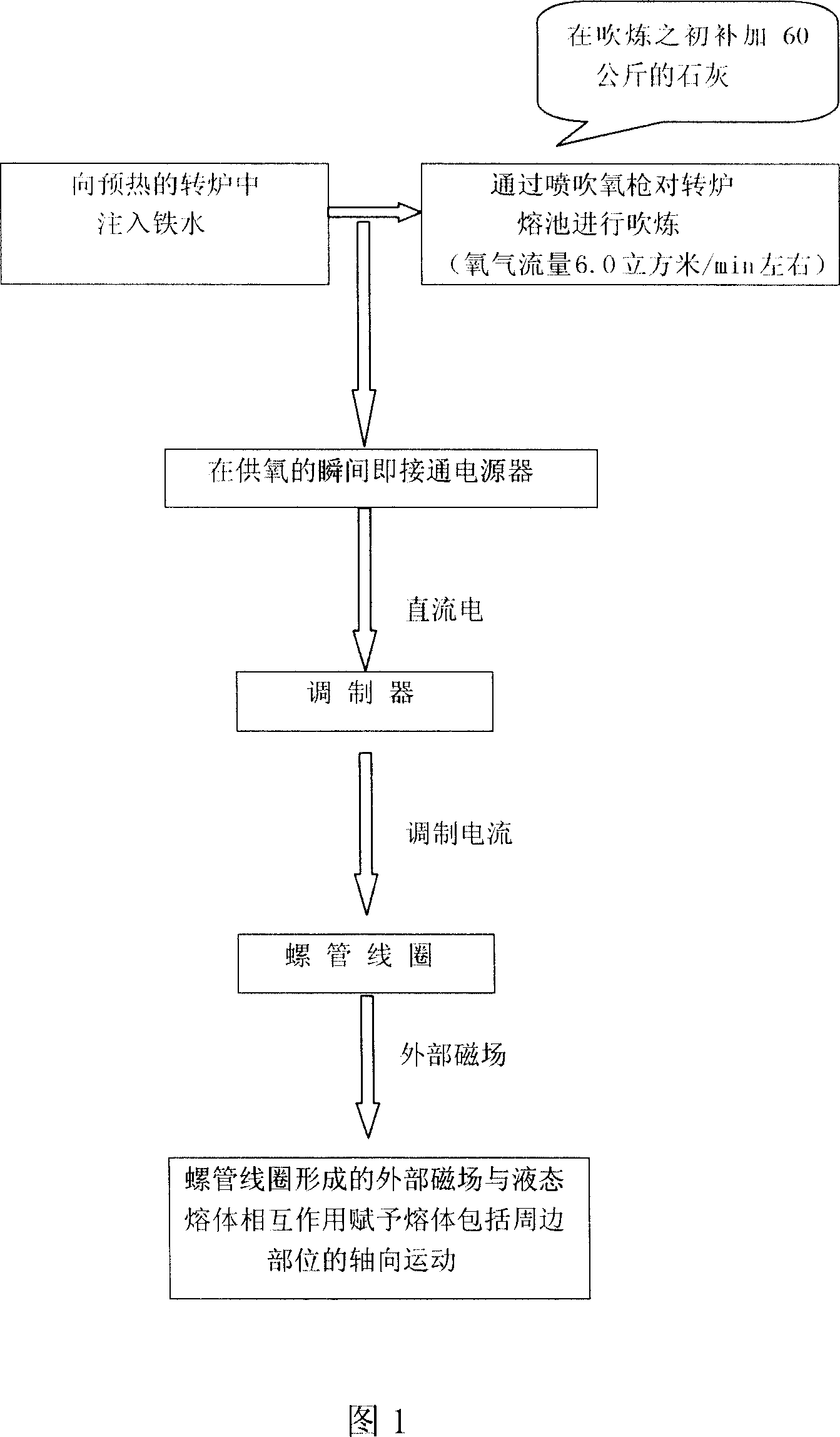

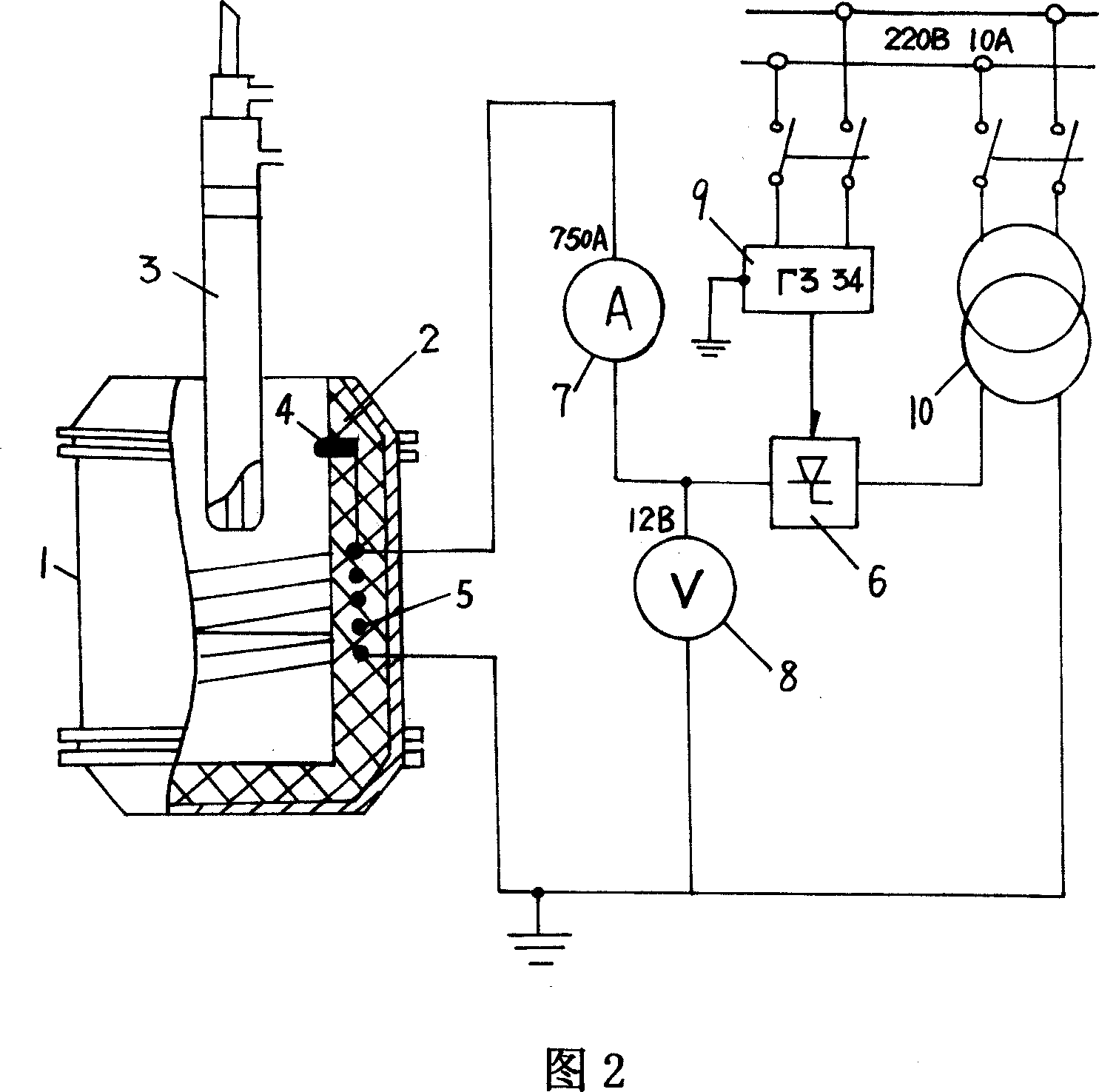

[0036]As shown in Figures 1 and 2, a converter smelting method is to establish a space magnetic field in the converter; provide the basic power required to establish the space magnetic field as direct current; pre-modulate the direct current before it acts on the space magnetic field forming end, To make the melt in the converter move from the periphery to the center. In actual operation, the solenoid coil fitted in the converter can be used to form a converter space magnetic field; the basic power supply for the solenoid coil is direct current; before the direct current is sent to the solenoid coil, it is pre-modulated, To make the melt in the converter move from the periphery to the center. In the invention, during the smelting process of the converter, iron-containing materials of 1-40 kg / ton of steel are added to the converter. The above-mentioned iron-containing material is ore, iron oxide scale, sintered ore, pellet ore or a mixture thereof. The present invention can a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com