Plant powder type fuel boiler and its burning method

A plant powder and fuel technology, applied in combustion methods, combustion equipment, fuel supply, etc., can solve the problems of inability to meet temperature and pressure, low combustion efficiency, etc., achieve low pollution, high economic and social benefits, and increase farmers' income. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

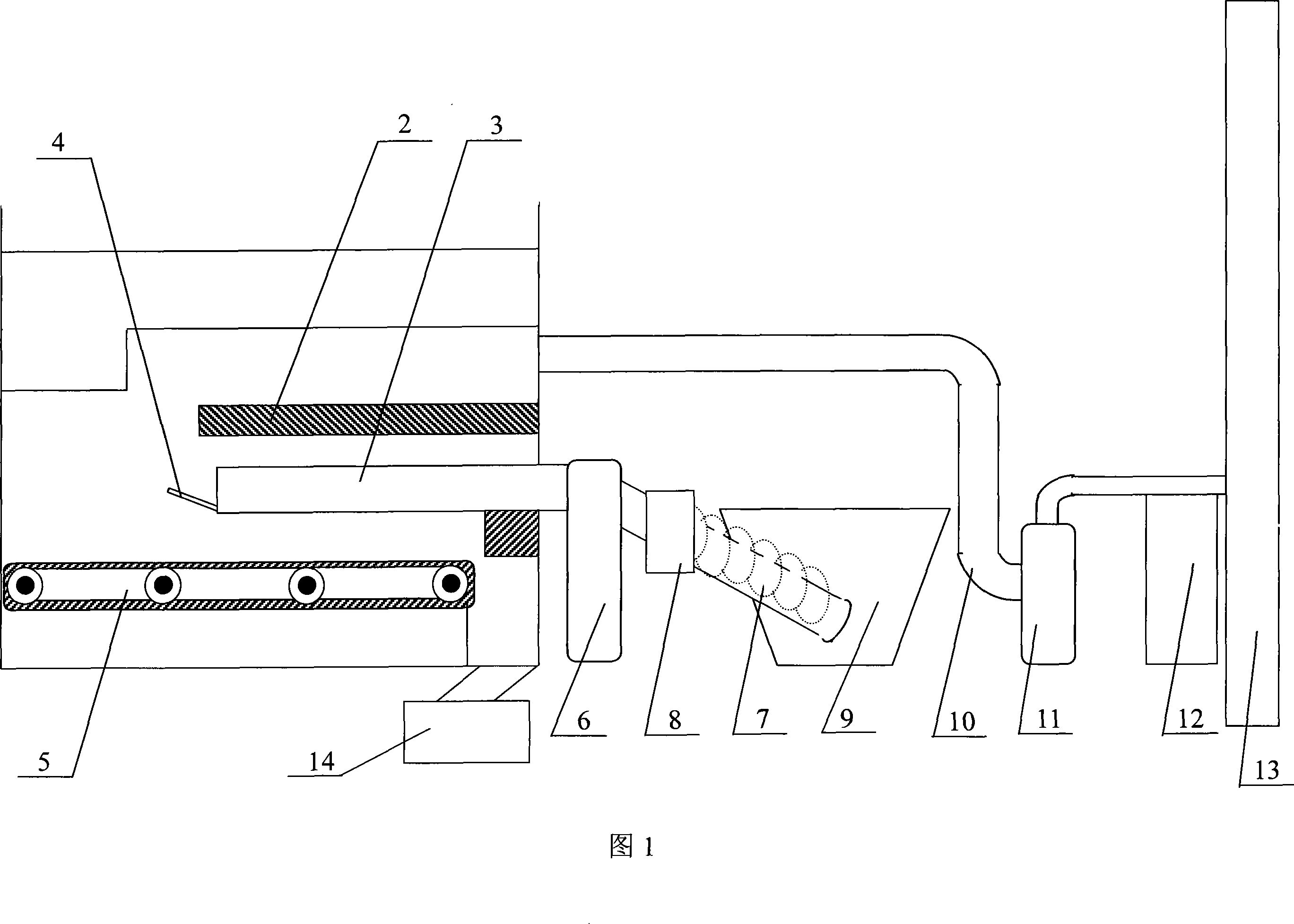

[0027] Embodiment 1, referring to Fig. 1, plant powder type fuel boiler, it comprises furnace body 1, is provided with chain fire grate 5 near the bottom of combustion chamber in furnace body 1, is provided with feed port, flue mouth on furnace body 1 wall And the ignition port, a slag outlet is provided under the furnace body 1, the flue leading wall 2 is fixed on the furnace wall in the furnace body 1, located between the flue port and the feed port and parallel to the chain grate 5, and the fan feeds One end of the pipeline 3 extends into the combustion chamber from the feed port, and the other end is connected to the feeding box 8 and the feeding machine 7 through the fan 6 outside the furnace body 1. The feeding machine 7 is driven by a speed-regulating motor to drive the screw auger The rod is connected with the material box 9, and the powdery fuel is quantitatively transferred to the material box 8; the slag outlet of the furnace body 1 is connected with the screw slag o...

Embodiment 2

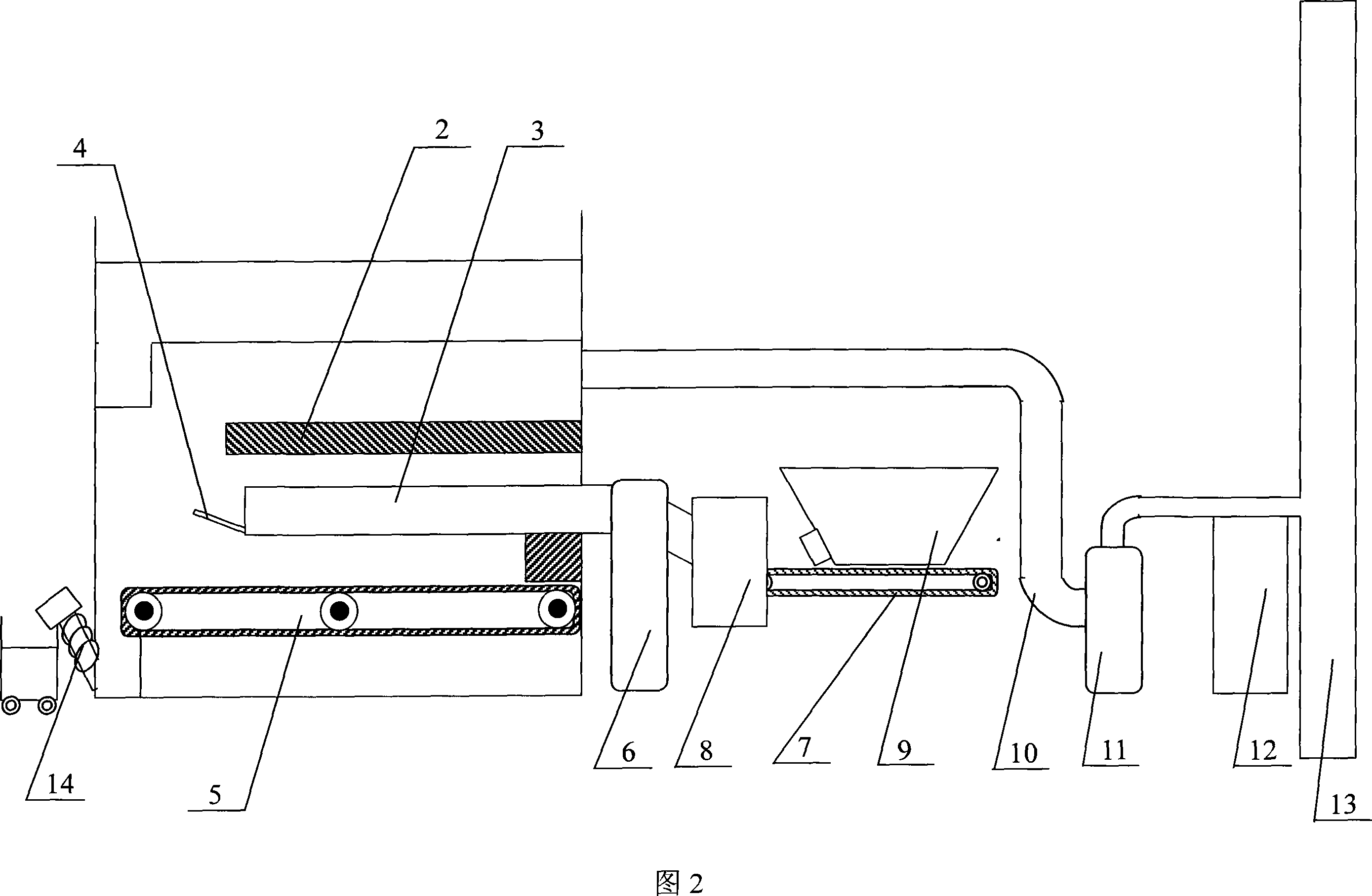

[0031] Embodiment 2, referring to Fig. 2, plant powder type fuel boiler, it comprises furnace body 1, is provided with chain fire grate 5 near the bottom of combustion chamber in furnace body 1, is provided with feed port, flue mouth on furnace body 1 wall And the ignition port, a slag outlet is provided under the furnace body 1, the flue leading wall 2 is fixed on the furnace wall in the furnace body 1, located between the flue port and the feed port and parallel to the chain grate 5, and the fan feeds One end of the pipeline 3 extends into the combustion chamber from the feed inlet, and the other end is connected with the feeding box 8 and the feeding machine 7 through the fan 6 outside the furnace body 1. The material box 9 is connected, and the powdered fuel is quantitatively transferred to the upper material box 8; the slag outlet of the furnace body 1 is connected with the screw slag machine 14, and the slag machine 14 is installed at the slag outlet of the furnace body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com