Spiral step falling distribution type separating tower column plate

A separation tower, distributed technology, applied in distillation separation, separation methods, chemical instruments and methods, etc., can solve the problems of reduced effective utilization area, poor efficiency and operation flexibility, etc., to maintain uniformity and improve relative flow rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

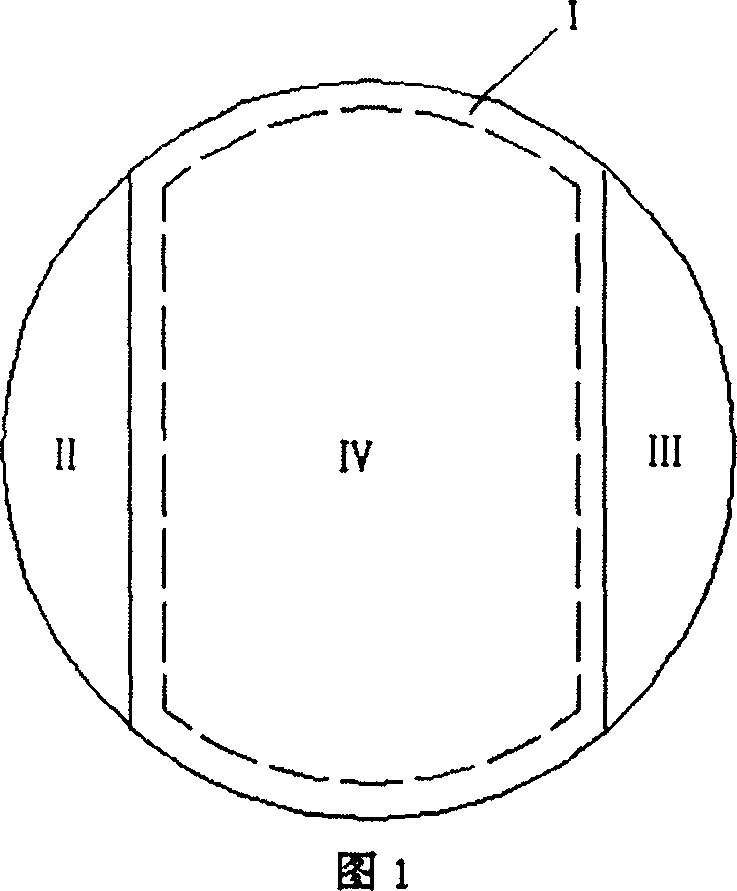

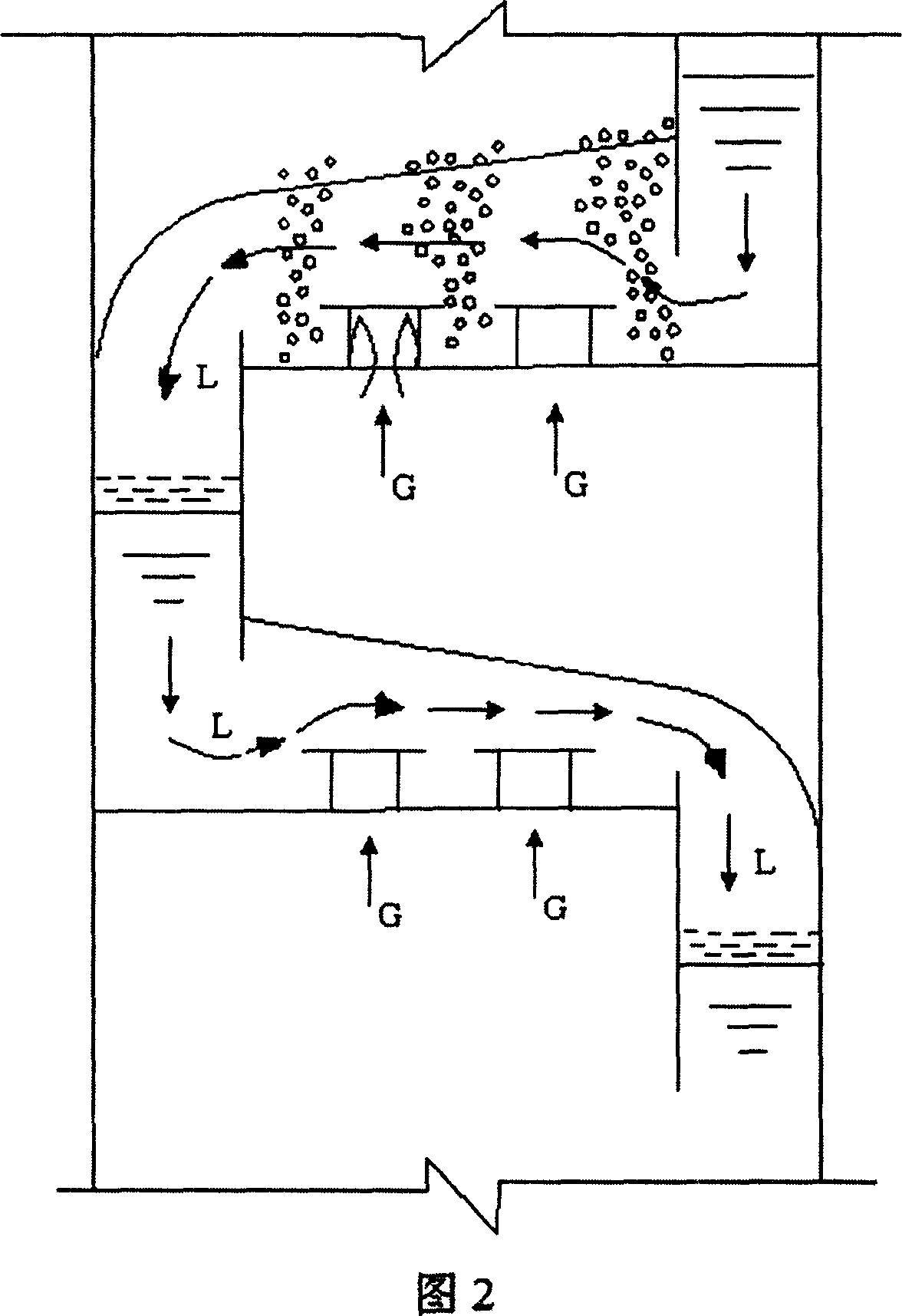

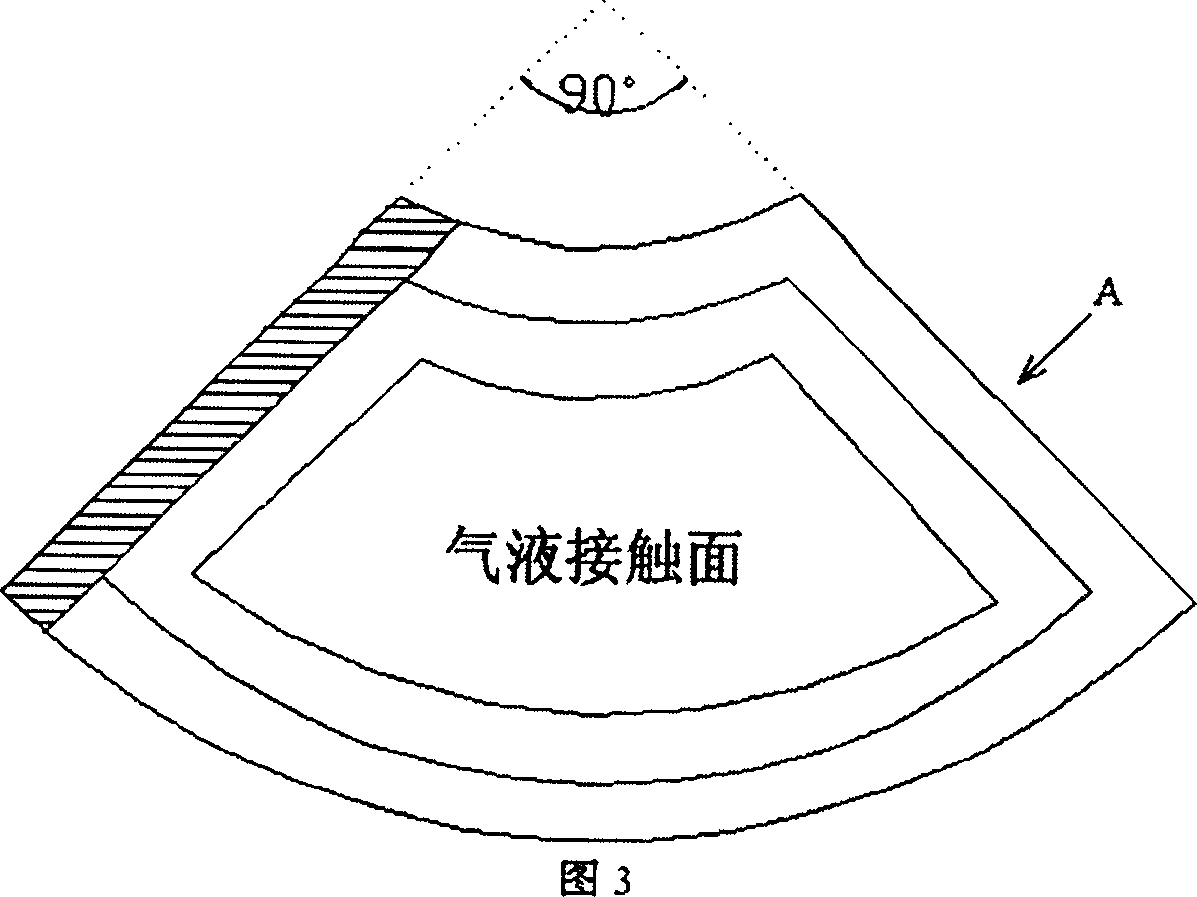

Embodiment 1

[0030] For the ethanol-water rectification separation system, the diameter of the experimental tower used is 400mm. Originally, 5 traditional float valve trays were used for experiments. The ratio of the total cross-sectional area is about 82%, and the F1 type float valve is used. Adopt spiral step descending distributed separation column tray of the present invention, remove the circle of 1 / 9 area from the center of tray tray of equal size, then cut into equal parts into n=5 pieces, obtain 25 fan-shaped trays (1), press The spiral ladder method is welded to the support tube with the same diameter as the circle cut off from the tray. The total effective mass transfer area of the tray is about 11% higher than that of the original tray, and the opening rate of the single plate is higher than that of the traditional valve tray. 10%, and the period of liquid flowing through the tray becomes longer, which is more conducive to the exchange between gas and liquid. It has been meas...

Embodiment 2

[0032] Air-water system, rectifying tower experimental tower diameter 800mm, respectively adopt traditional tray and fixing method and the sector tray and fixing method described in the present invention; The ratio of the mass transfer area to the total area of the tower is about 70%, and the installation height between the trays is 300mm. When fixing by spiral ladder descending method, cut each traditional tray into n=4 fan-shaped trays (1), the ratio of the center cut part to the total area of the tray is 1:16, and the installation height between the fan-shaped trays (1) 75mm, the outlet of the overflow weir (2) adopts a tooth shape, the angle α between the tooth bottom line and the horizontal plane is 1°, the effective mass transfer area is increased by nearly 22% compared with the traditional monolithic tray, and the degree of liquid backmixing on the plate is obvious drop, the liquid level drops by nearly 50%, the entrainment of mist drops by nearly 40%, and the separ...

Embodiment 3

[0034]Ethanol-water system, the diameter of the experimental tower is 800mm, the ratio of the cut part of the center of the traditional tray to the total area is 1:16, and then it is equally divided into n=6 fan-shaped trays (1), a total of 6×10=60 pieces The fan-shaped tray (1) (the original tower is 10 trays), the overflow weir (2) adopts a flat head weir, and the angle α between the line connecting the top edge of the weir height and the horizontal plane is 2°, and every 3×6=18 blocks A downcomer (6) is arranged on the fan-shaped tray, and the area of the downcomer (6) accounts for 1 / 2 of the area of the fan-shaped tray (1), and the area of the fan-shaped tray (1) below it is increased by 1 / 2 as the receiving Liquid tray, that is, cut the fan-shaped tray with the downcomer (6) into 1 / 8 size when cutting the traditional tray, and cut the fan-shaped tray with the liquid receiving tray into 3 / 8 size after the transformation. Compared with the original tray, the effective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com