Novel coupling film separating method and device used in gas separation

A gas separation membrane and gas separation technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of poor chemical stability, complexity of olefin carriers, and restricting the development of industrialization process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Example 1 Theoretical simulation of the separation performance of ethylene / ethane passing through the separation unit

[0062] The composite gas separation membrane with polyetherimide (PEI) porous membrane as the base membrane and polydimethylsiloxane (PDMS) as the composite separation layer material is used as the gas separation membrane of the gas separation membrane bag. The carrier solution is 4M AgNO 3 solution. The loss and renewal of the carrier solution is not considered in the simulation, and the flow velocity of the carrier solution in the channel of the carrier solution is 0m / s. The raw gas is pure ethylene and ethane. Separation performance of composite gas separation membranes with ethylene and ethane in AgNO 3 The physical properties in the carrier solution are shown in Table 1. The thickness (d) of the carrier solution channel was 300 μm. Ethylene is carried out in the form of dissolution and diffusion in the composite gas separation membrane, in th...

Embodiment 2

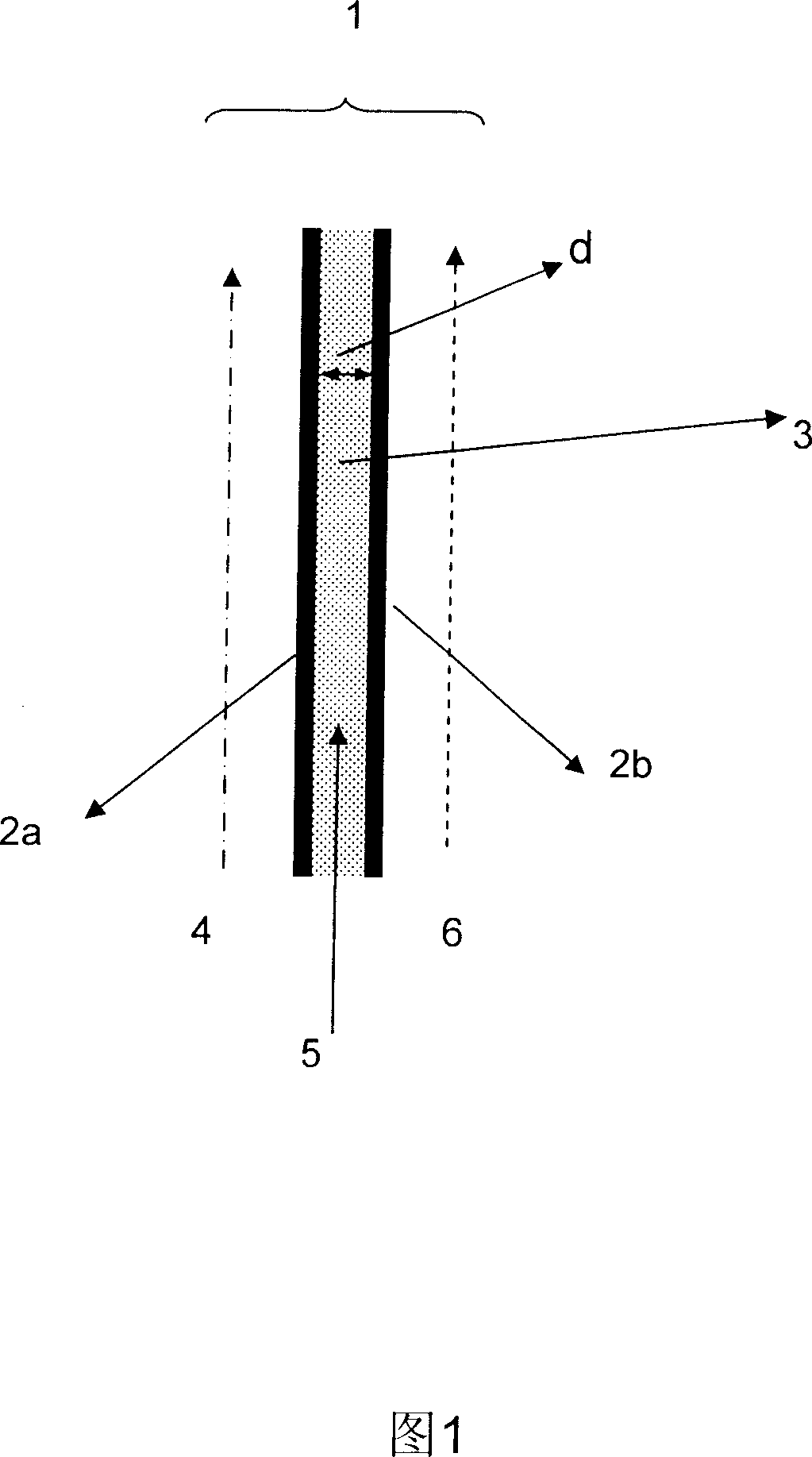

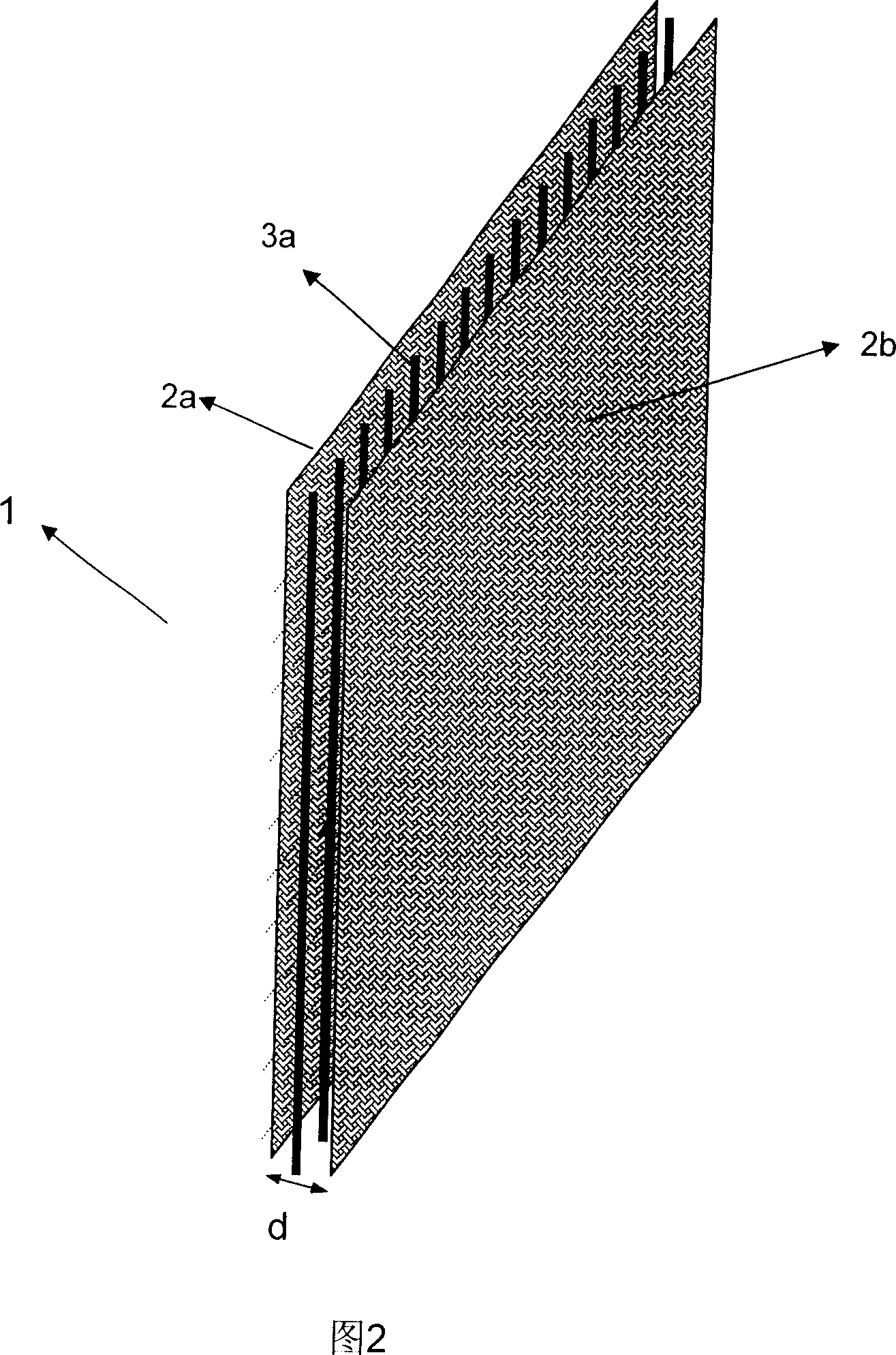

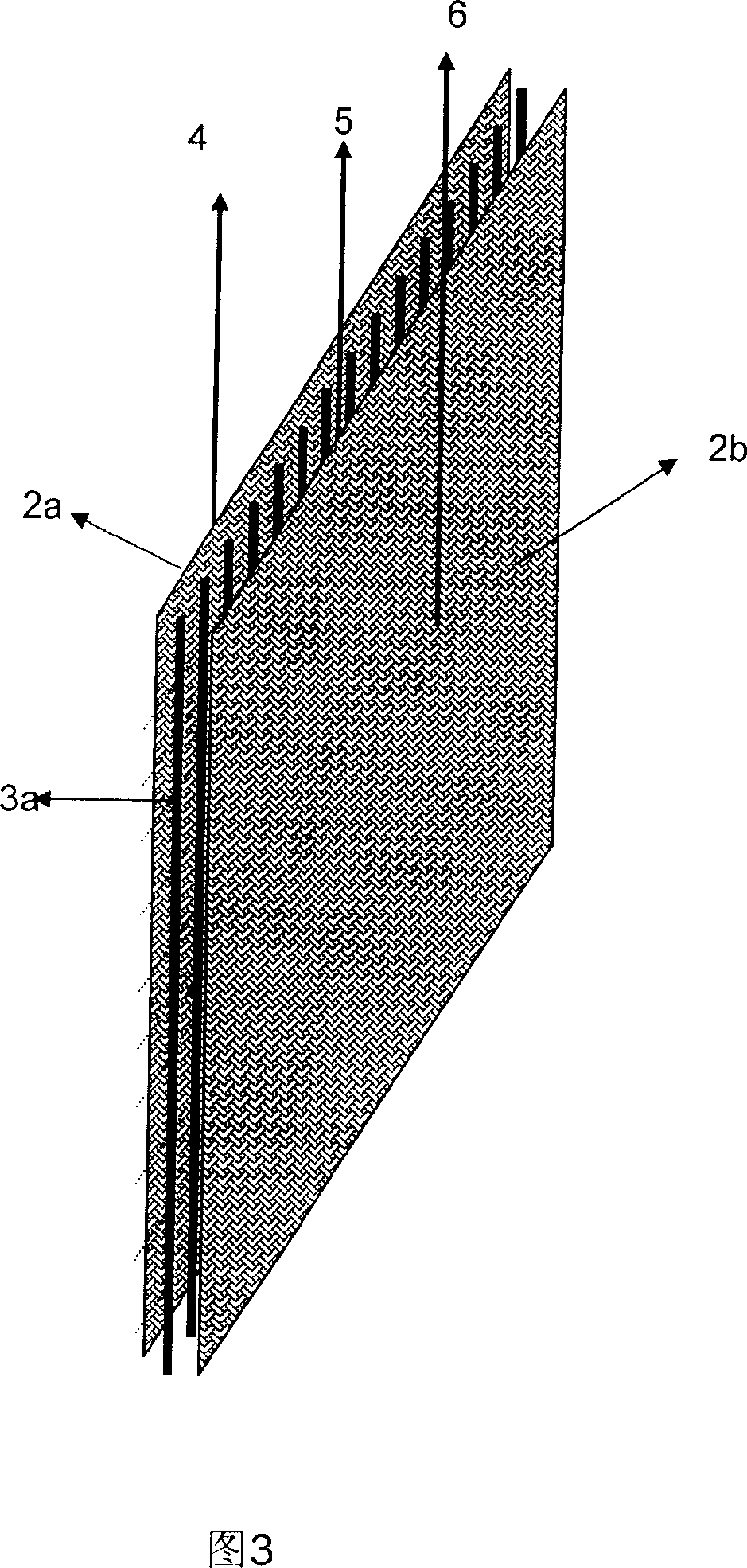

[0063] Example 2 Sandwich gas separation membrane bag

[0064] In the present invention, the gas separation membrane bag is defined as a basic separation unit, forming a sandwich structure of gas separation membrane-carrier solution-gas separation membrane. Figure 9 depicts a schematic diagram of the structure of a basic gas separation membrane bag. A carrier solution channel with a certain thin layer thickness (d) is formed between the gas separation membranes 2a and 2b, and the carrier solution flow 5 flows in the channel at a certain speed to replenish and renew the carrier solution. A spacer 3a of a certain thickness may be placed between the gas separation membranes to support the gas separation membranes. At the same time, the thickness of the carrier solution, that is, the distance (d) between the gas separation membranes can be adjusted by the thickness of the spacer 3a between the gas separation membranes. The carrier solution 3 is filled in the space between the ga...

Embodiment approach 3

[0068] Embodiment 3 Separation device

[0069] Several gas separation membrane bags can be stacked to produce a plate-and-frame membrane separation unit or a roll-type membrane separation unit. A certain distance is maintained between adjacent gas separation membrane bags to form passages for raw gas or permeate gas. Figure 13 illustrates a superimposed schematic diagram of the membrane elemental separation elements for the preparation of the membrane separation unit. The M th gas separation membrane bag and the M+1 th gas separation membrane bag form a raw gas channel 7 . Its spacing (df) can be adjusted through the net or frame. The M+1th gas separation membrane bag and the M+2th gas separation membrane bag form a permeate gas channel 8 . Its spacing (dp) can also be adjusted through a mesh or frame. The M+2 basic membrane separation element and the M+3 basic membrane separation element form the raw gas channel 7 . Raw material gas channels and permeate gas channels app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com