Synchronous control method for stern hydraulic workbench lifting

A working platform, synchronous control technology, applied in the direction of using feedback control, lifting frame, lifting device, etc., can solve the problems of difficult hydraulic multi-cylinder high-precision synchronization, poor dynamic quality and adaptability, inconsistent cylinder stroke speed, etc. Achieve the effect of solving the problem of high-precision synchronous lifting, novel control ideas, and improved stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

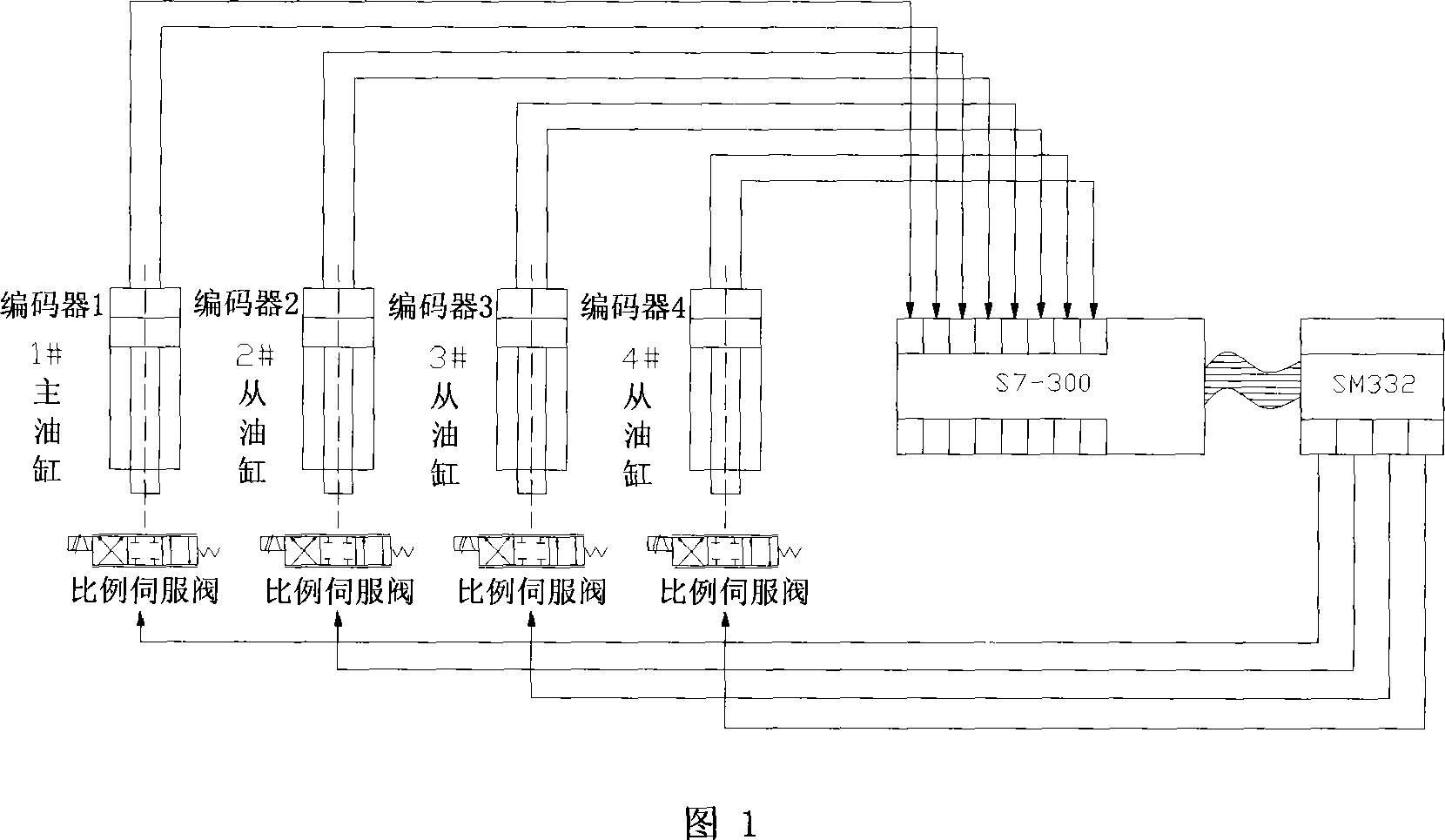

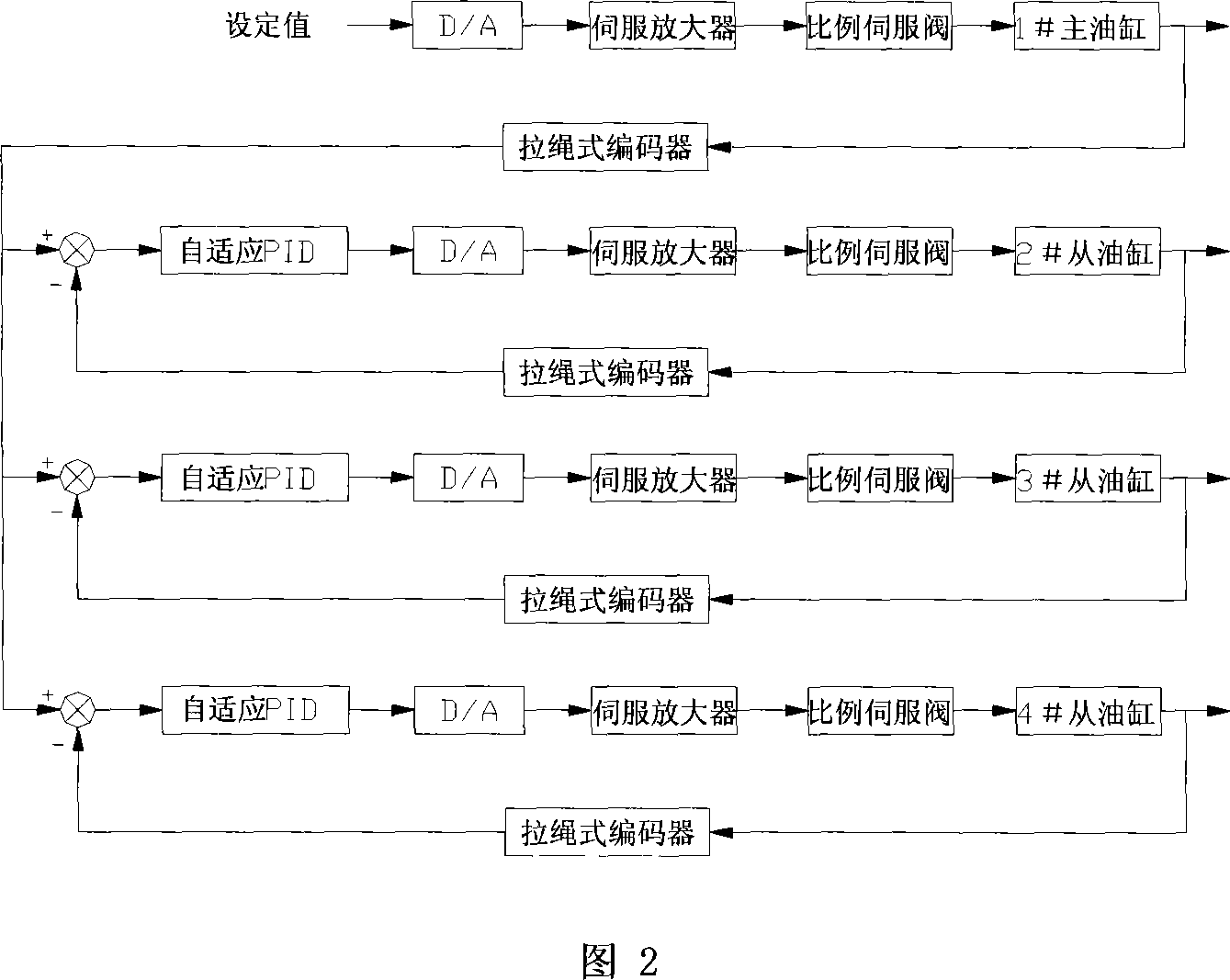

[0020] The present embodiment is carried out on the 250-ton stern hydraulic working platform. As shown in Figures 1 and 2, this embodiment adopts Siemens S7-300 series PLC as the control core of the system, the output of the analog output module SM332 controls the proportional servo valve, and the pull-rope linear displacement sensor is fixed on the moving part of the piston rod. The sensor is installed on the casing of the box. When the cylinder piston moves up and down, it drives the pull rope to make a reciprocating linear motion, and its precise position signal is output by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com