Method of separating and purifying o/p-dihydroxy benzene prepared by phenol hydroxylation

A technology for hydroxylation of phenol and hydroquinone, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of increasing energy consumption for de-catechol, equipment manufacturing, and maintenance costs, and achieves The effect of energy consumption reduction, carbonization prevention, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

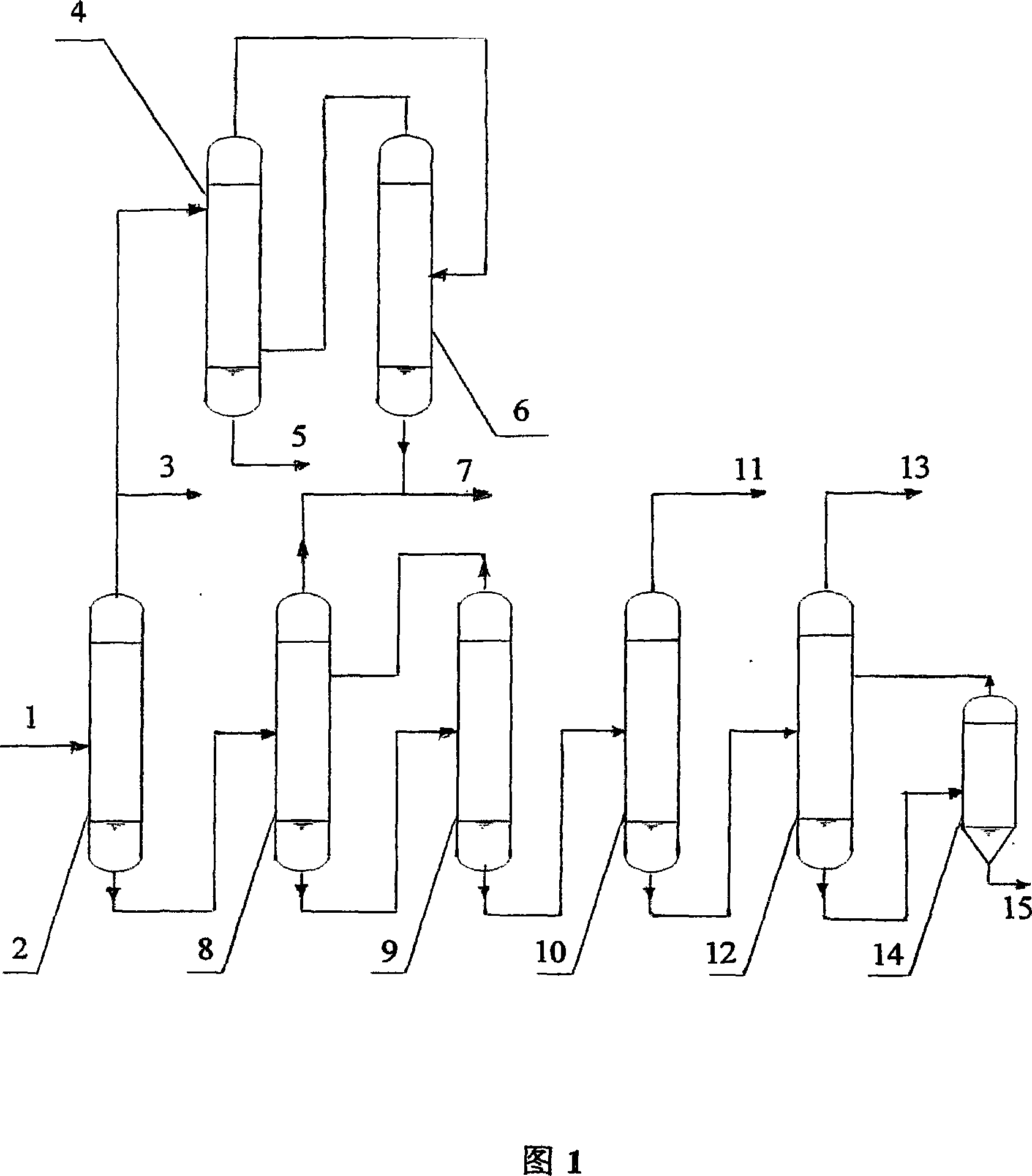

[0024] The raw material liquid is sent into the dehydration tower 2 at 211.9kg / h, and the composition of the raw material is shown in Table 1.

[0025]The dehydration tower 2 is operated under normal pressure, the reflux ratio is 0.2, and the temperature of the tower kettle is 185-190°C. An aqueous solution 3 containing 10.4% phenol is obtained at the top of the tower, 38% of which is sent to the extraction tower 4 to recover phenol 7, and the rest is reused in the circulating reaction system. The composition of the output from the tower kettle is shown in Table 2.

[0026] composition

water

phenol

Quinol

tar

Content / %

37.8

52.8

4.5

2.7

2.2

[0027] composition

water

phenol

Catechol

Quinol

tar

Content / %

0.8

83.1

7.7

4.6

3.8

[0028] The 3 fractions of the phenol aqueous solution are sent to the rotary disk extraction c...

Embodiment 2

[0039] The raw material liquid is sent into the dehydration tower 2 at 211.9kg / h, and the composition of the raw material is shown in Table 7.

[0040] composition

water

phenol

Catechol

Quinol

tar

Content / %

57.8

32.8

4.5

2.7

2.2

[0041] composition

water

phenol

Catechol

Quinol

tar

Content / %

0.3

73.6

12.5

7.5

6.1

[0042] The dehydration tower 2 is operated under normal pressure, the reflux ratio is 0.5, and the temperature of the tower kettle is 185-190°C. A 10.0% aqueous solution containing phenol fraction is obtained at the top of the tower, 38% of which is sent to the extraction tower 4 to recover phenol, and the rest is reused in the circulating reaction system. The composition of the output from the tower kettle is shown in Table 8.

[0043] The phenol aqueous solution fraction is sent to the rotary disk extraction column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com