Method of reducing resistance of anode carbon block set

An anode carbon block and resistance technology is applied in the field of improvement of the internal structure of the anode carbon block group, which can solve the problems of reducing power efficiency and increasing power consumption per ton of aluminum, so as to improve power efficiency, reduce power consumption per ton of aluminum, and reduce iron and carbon. The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

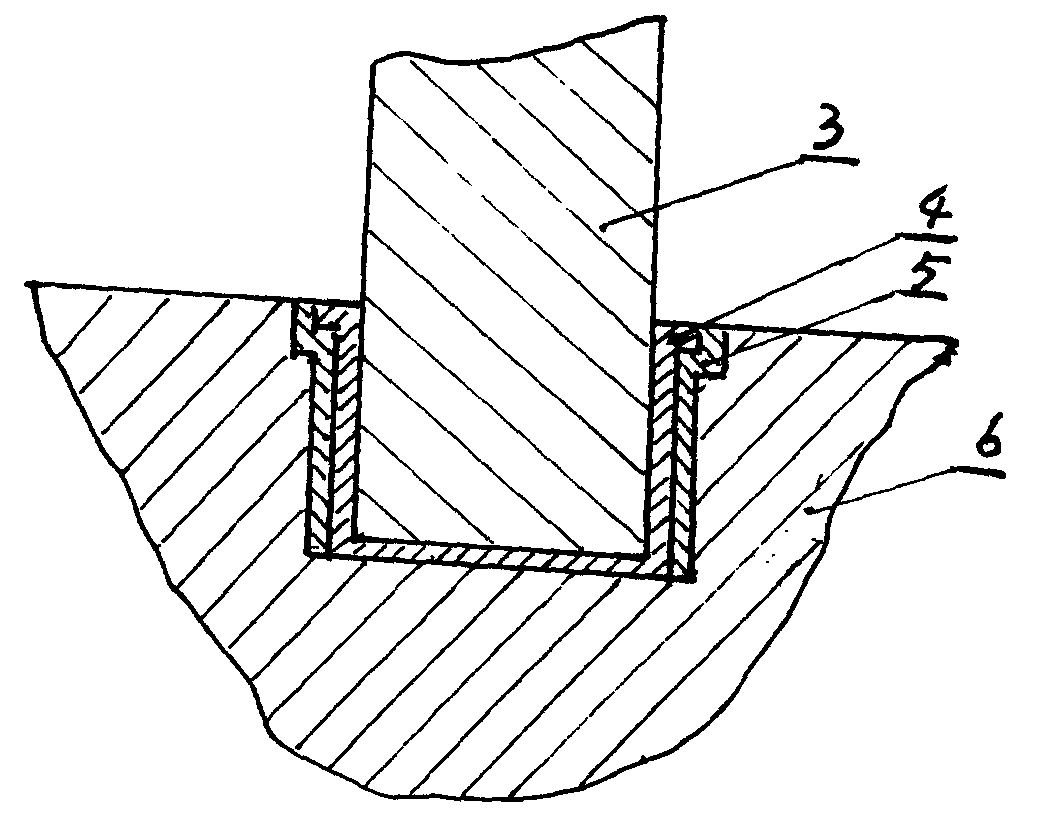

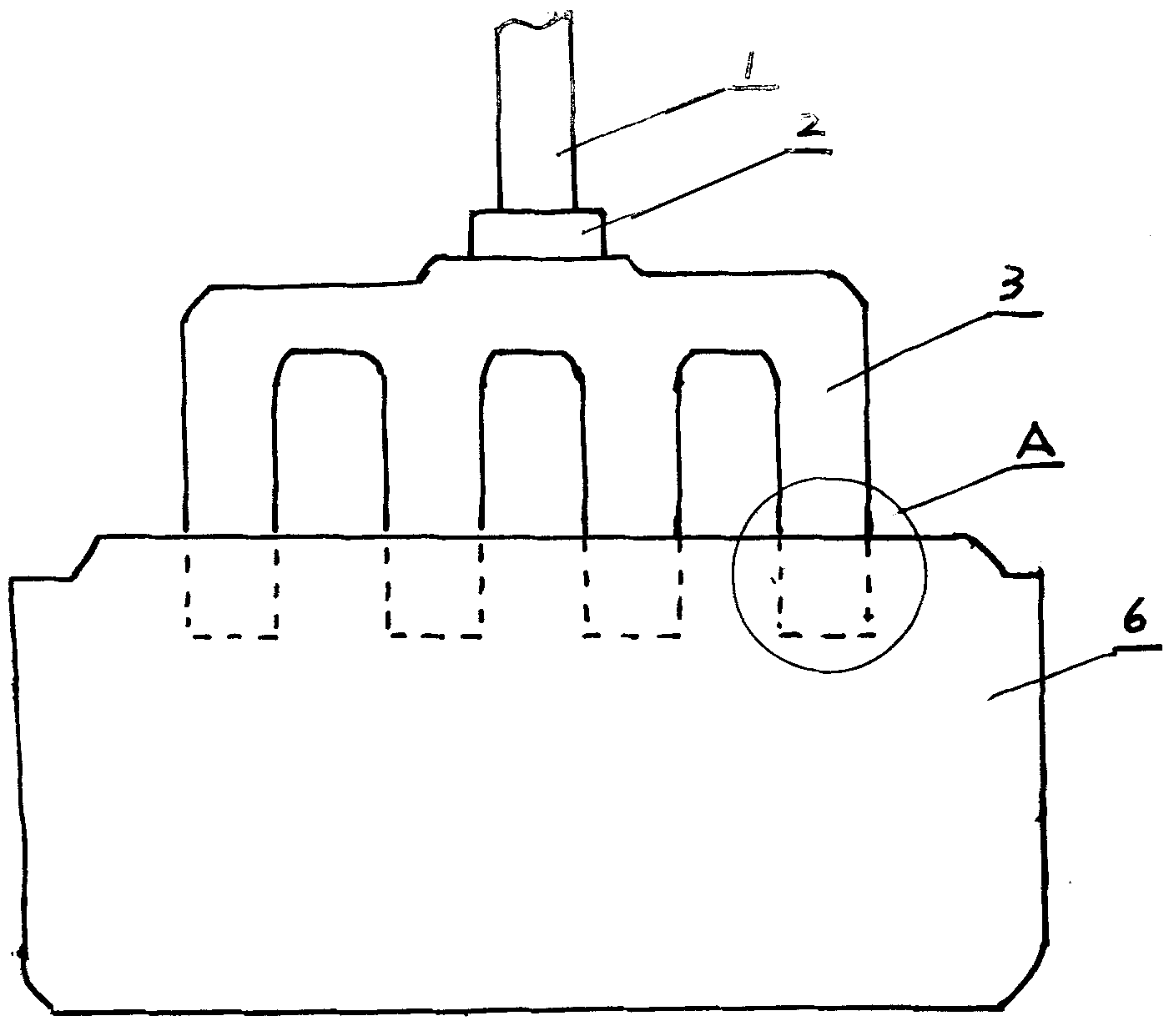

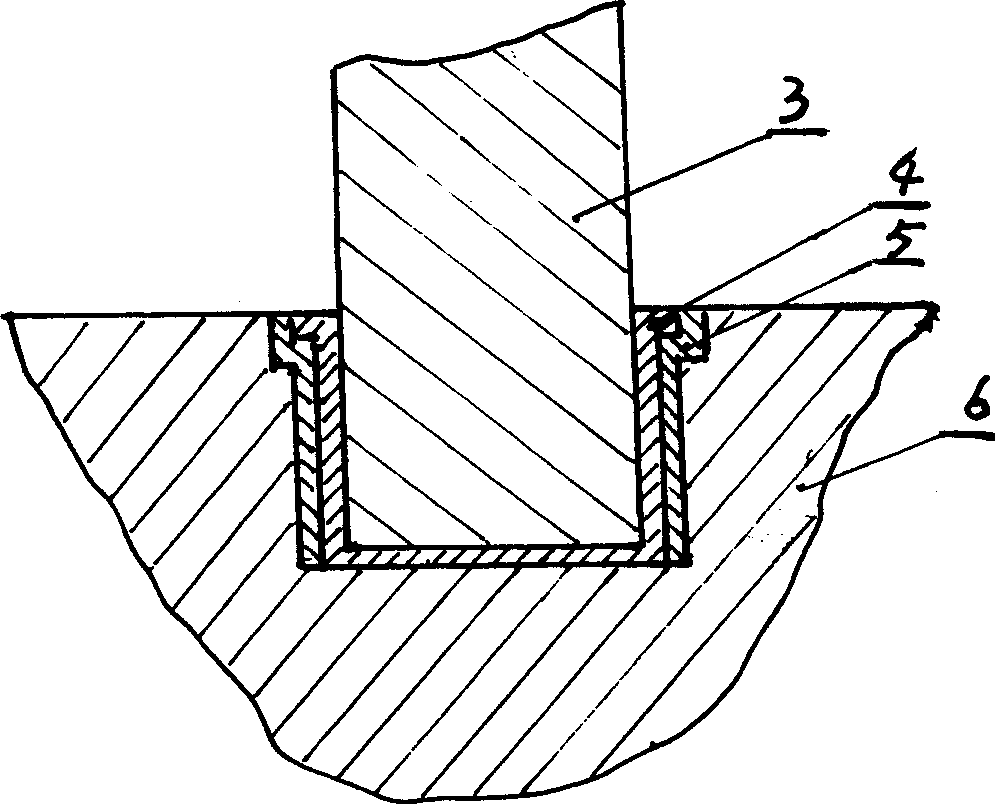

[0008] The anode carbon block group shown in accompanying drawing 1 and 2 is to form solid conductor (5) after pouring conductive slurry in the gap between the carbon bowl of phosphorus iron ring (4) and carbon block (6) and the cavity Partial cross-sectional view of the longitudinal side, the other longitudinal side is the same, but the length is different, omitted. Generally, the upper part of the anode carbon block group is an aluminum guide rod (1), and the lower part is connected with an aluminum-iron explosive block (2), an anode steel claw (3) and a carbon block (6), and the upper part of the carbon block (6) has a carbon Bowl, the legs of the anode steel claws (3) stretch into the carbon bowl, and there is a phosphorus iron ring (4) between the anode steel claws (3) and the carbon bowl. The conductive paste can be of many kinds, and it is prepared by adding the fine powder of the conductor into the solvent. The solvent should have good fluidity and volatility. For exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com