Modified polyolefin-based resin for treating glass fiber, surface-treated glass fiber and fiber-reinforced polyolefin-based resin

一种聚烯烃类树脂、酸改性聚烯烃的技术,应用在薄料处理、运输和包装等方向,能够解决界面研究、研究例子少、未能得到优异性能等问题,达到高可靠性、振动疲劳强度提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0129] (I-4) Preparation method of acid-modified polyolefin resin

[0130] As a method for preparing acid-modified polyolefin resins (polyolefin resins containing functional groups), Japanese Patent Application Laid-Open No. 8-143739, Japanese Patent Application Publication No. 2002-20560, Japanese Patent Application Publication No. 7-316239, Known methods described in Japanese Patent Laid-Open No. 8-127697 and Japanese Patent Laid-Open No. 7-232324.

[0131] The preparation method is not particularly limited. When the maleic acid modified polypropylene resin is prepared, for example,

[0132] (1) Reacting organic peroxides, maleic acid, and polypropylene in a solvent (solution method);

[0133] (2) Use Banbury mixer or extruder to melt and mix organic peroxide, maleic acid and polypropylene (melting method);

[0134] (3) Methods such as reacting maleic acid with thermally decomposed polypropylene (thermal decomposition method), (1) solution method, (3) thermal decomposition metho...

preparation example 1

[0292] Preparation Example 1: Acid-modified polypropylene resin for treating glass fiber

[0293] (1) Preparation of maleic acid modified polypropylene (EM)

[0294] (1-1) Modification method-1: Melting method (EM-1~9, EM-11 and EM-12)

[0295] As shown in Table 2 below, polypropylene, maleic acid, and organic peroxide were put into a twin-screw extruder with vents, and melt-kneaded under specified conditions to obtain maleic acid-modified polypropylene.

[0296] The components that can be extracted with boiling methyl ethyl ketone contained in the obtained maleic acid-modified polypropylene are removed by the following purification method or washing method.

[0297] (1-2) Purification method (EM-1~8)

[0298] The maleic acid-modified polypropylene obtained above was heated (about 130°C) while stirring in p-xylene to completely dissolve it, and the solution was poured into methyl ethyl ketone for reprecipitation. After filtration, vacuum drying (130°C x 6 hours) was performed.

[...

manufacture example 2

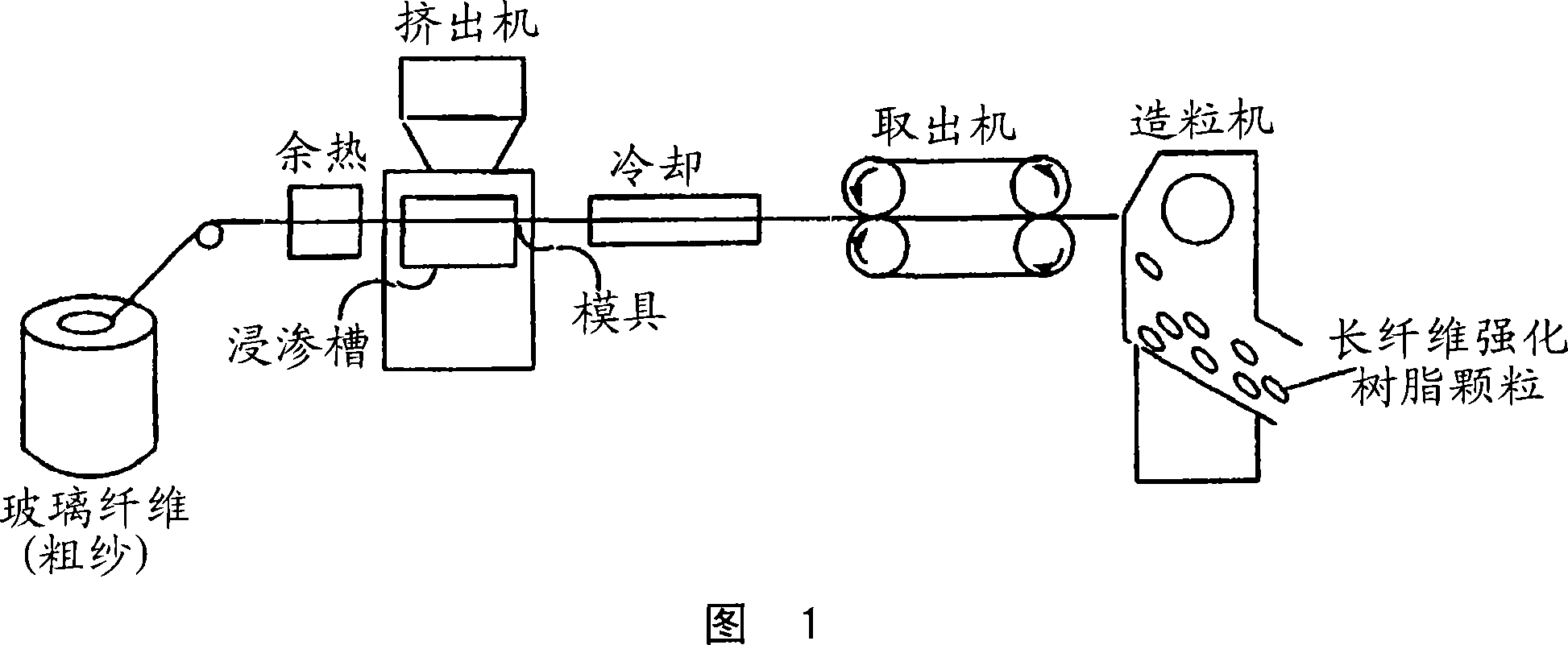

[0364] Production Example 2: Production of surface-treated glass fiber (GFEM)

[0365] As shown in Table 4 below, a sizing agent containing maleic acid-modified polypropylene and a silane coupling agent for glass fiber treatment prepared by the above-mentioned production example 1 was used to treat E-glass fibers with a diameter of 17 μm (specific gravity 2.55 g / cm 3 ) After heating and drying, the roving is made.

[0366] [Table 4]

[0367] Sizing agent

Of treated glass fiber

EM adhesion amount

(Mass%)

(CP)

Surface treatment resin

(EM)

Proportion

EM / CP

GFEM-1

CP-1

EM-1

6

0.40

GFEM-2

CP-1

EM-1

6

0.40

GFEM-3

CP-2

EM-1

6

0.40

GFEM-4

CP-1

EM-2

6

0.40

GFEM-5

CP-1

EM-3

6

0.40

GFEM-6

CP-1

EM-4

6

0.40

GFEM-7

CP-1

EM-5

6

0.40

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com