Open-pored polyurethane foam without skin formation, formulation for the production thereof and use thereof as a carrier material for cell and tissue cultures or medicaments

A technology of polyurethane foam and formulation is applied in the field of formulation of open-cell polyurethane foam to achieve good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

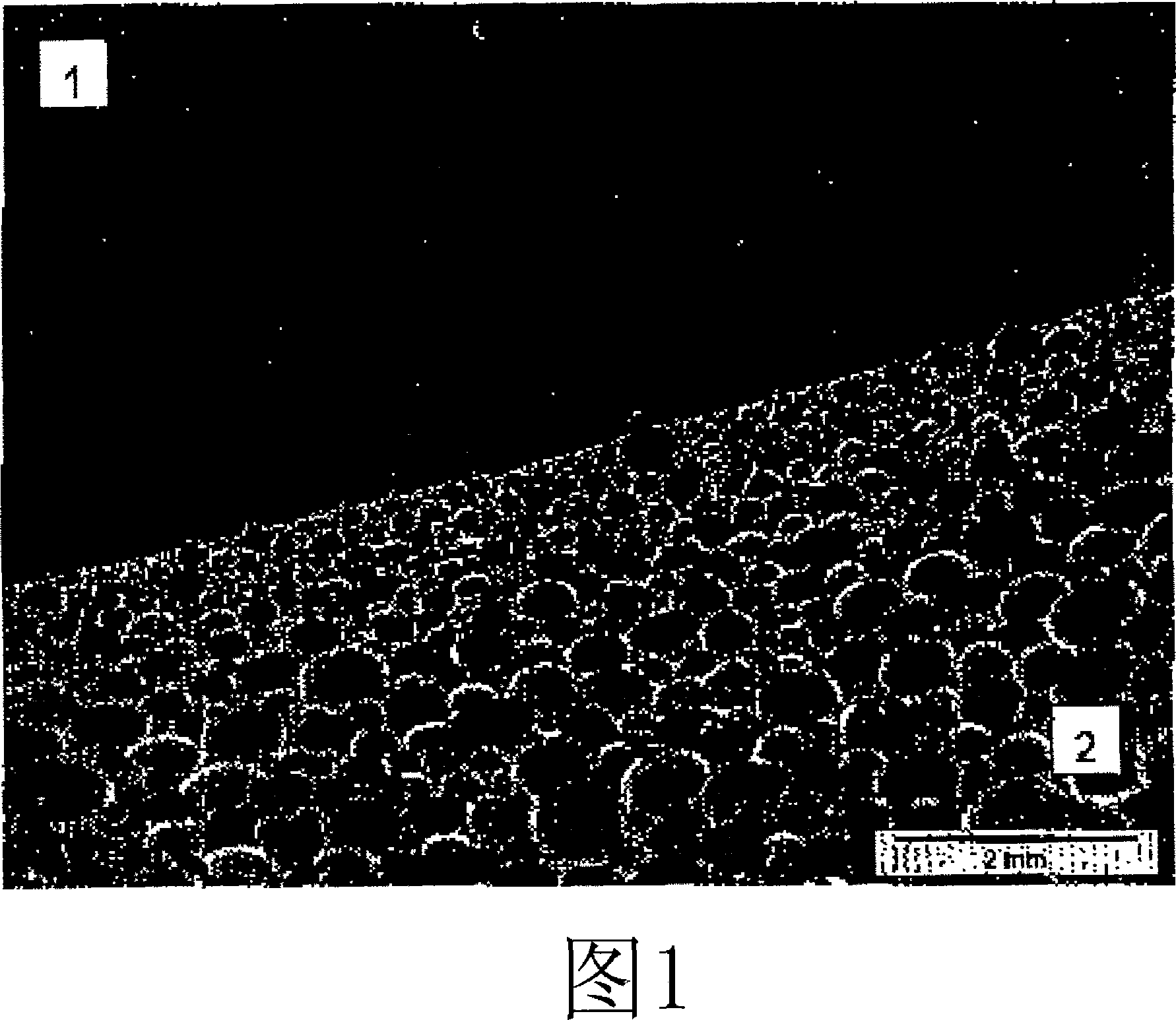

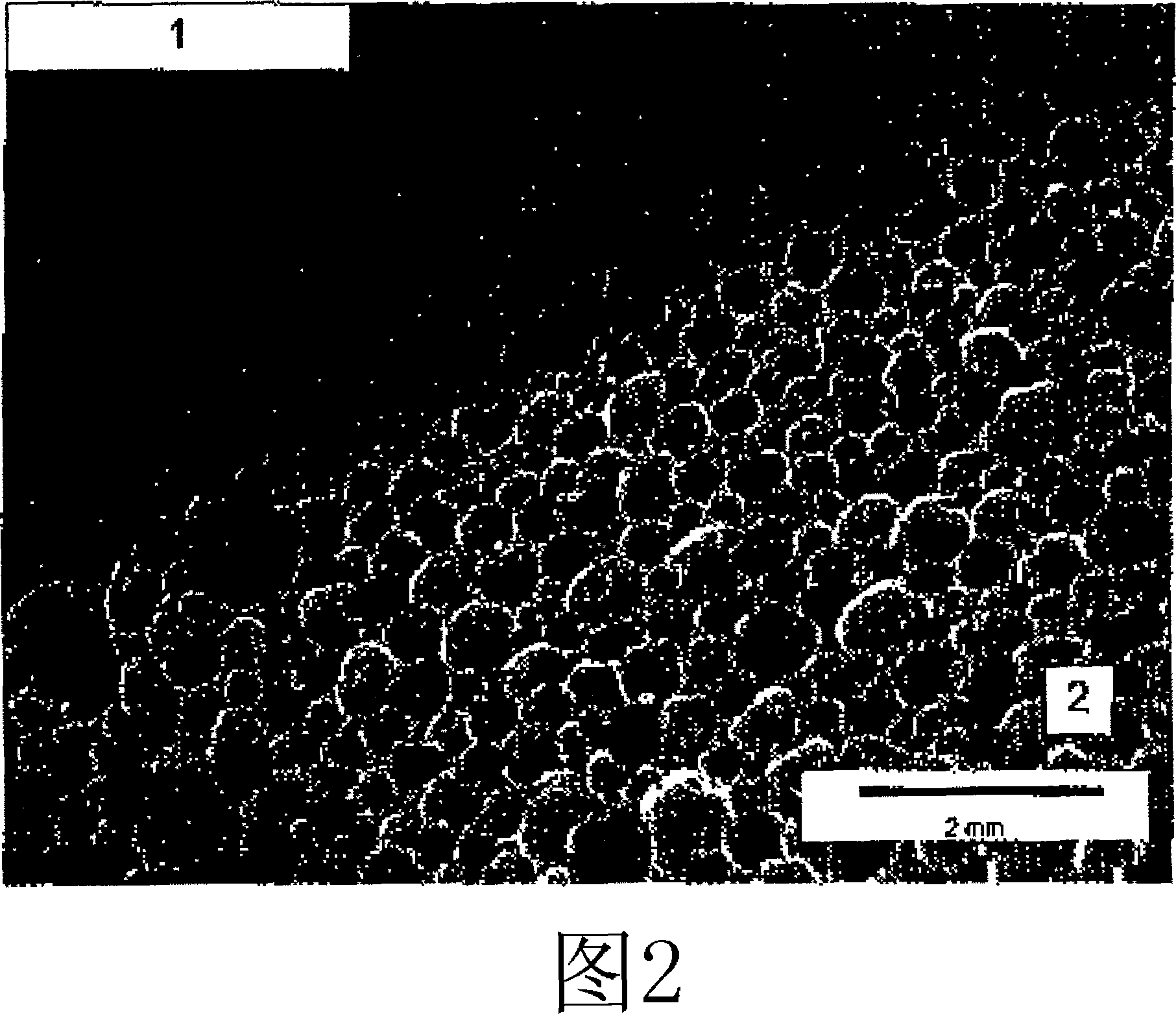

[0056] 24% polycaprolactone diol (M n =1,250), 20% polycaprolactone triol (M n =900), 36% isophorone diisocyanate, 1.6% polyethylene glycol-block-polypropylene glycol-block-polyethylene glycol (M n =14,600), 4% triethanolamine, 0.08% water, 2.5% dextrose (equivalent to 3.9% based on polyol component containing all components except diisocyanate), 0.25% The formulation of diazabicycloundecene and 11.57% cyclohexane was thoroughly mixed at 60°C and then heated to 75°C for 4 hours in a petri dish. The resulting shaped articles have uniform porosity. Figure 2 clearly shows that the interconnectivity of the pores is well developed. In contrast to Comparative Example 1, in this case the pores are also open on the surface. After foam preparation, it was placed in boiling water for 1 hour to improve its hydrophilicity. They can then be easily loaded, for example, with a fibrin adhesive containing cell cultures such as chondrocytes, fibroblasts or osteoblasts.

example 2

[0058] The formulation as described in Example 1 was cast in a silicone mold with only one door. Silicone molds have been fabricated from stereolithographic models of the human ear. The mold was preheated to 70°C and this temperature was maintained for 8 hours for curing. A uniformly foamed shaped article is obtained. The pores are open on the surface and are interconnected with internal pores. In the case of such shaped articles, the hydrophilicity is also improved by boiling in water or saline. The shaped objects obtained can be easily filled with a mixture of cells, fibrin adhesive and various growth factors for the preparation of implants.

example 3

[0060] Example 3 demonstrates the suitability of the biocompatible nucleating agent tricalcium phosphate in the form of nanoparticles in formulations according to the invention.

[0061] Disperse 40% tricalcium phosphate nanoparticles as nucleating agent in polycaprolactone diol (M n =2000). A preparation containing 14.0% of the dispersion and 21.3% of polycaprolactone diol (M n =2,000), 21.3% polycaprolactone triol (M n =900), 17.7% isophorone diisocyanate, 1.8% polyethylene glycol-block-polypropylene glycol-block-polyethylene glycol (M n = 14,600), 2.1% triethanolamine, 0.07% water, 2.1% dextrose (equivalent to 2.55% based on polyol component including all components except diisocyanate), 1.4% The formulation of octanol, 0.21% diaminobicycloundecene and 18.02% cyclohexane was mixed thoroughly at 55°C and then heated to 75°C for 4 hours in a petri dish. The resulting shaped articles have uniform porosity. The pores are well interconnected and the pores are open on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com