Heat circulation device for central baking tobacco leaves

A thermal cycle device and tobacco leaf technology are applied in the fields of tobacco, tobacco preparation, application, etc., which can solve the problems affecting the production of high-quality products of tobacco enterprises, lack of economic compensation for hard work, and increase the consumption of coal resources, and achieve a unified tobacco leaf. Roasting standard, improving tobacco leaf quality, good saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

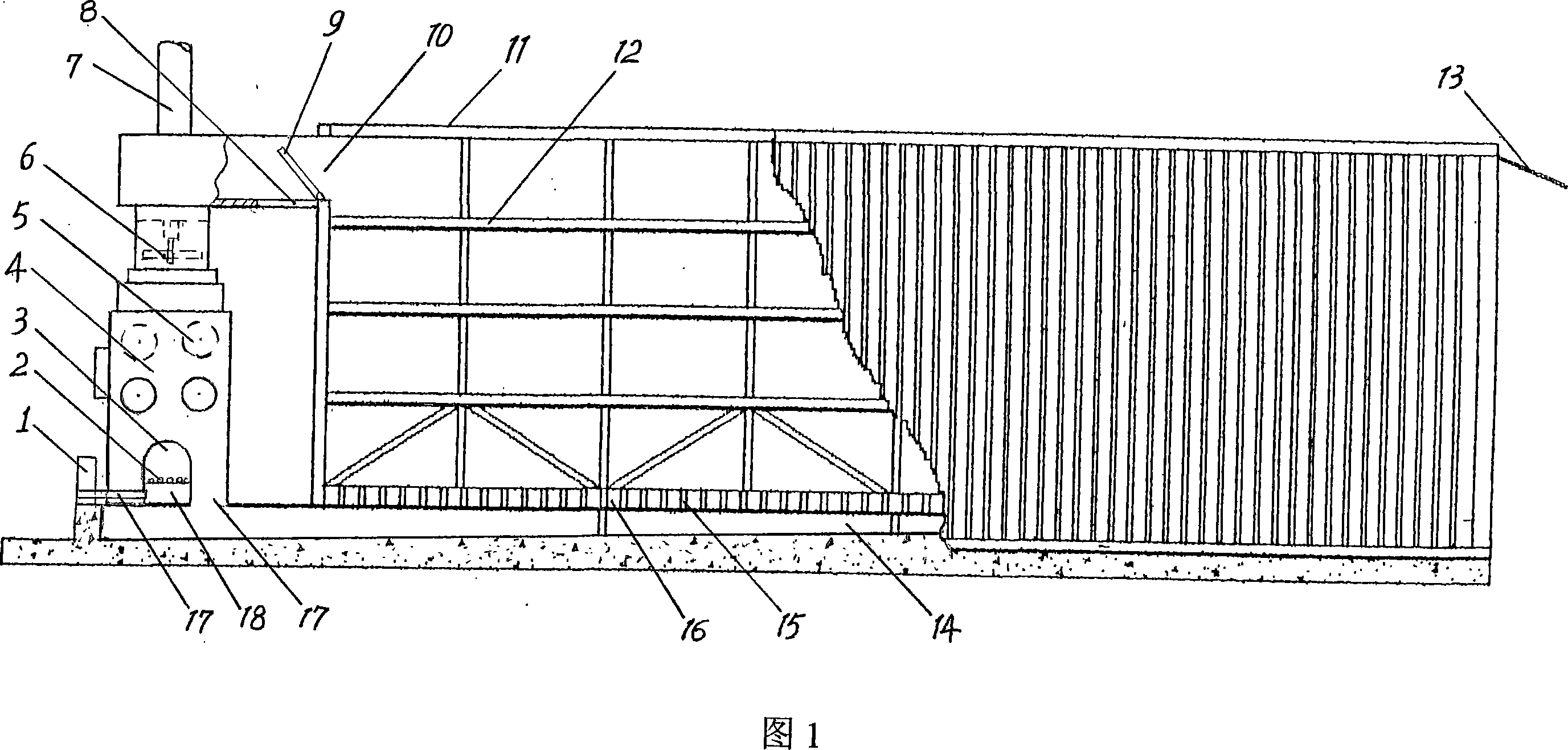

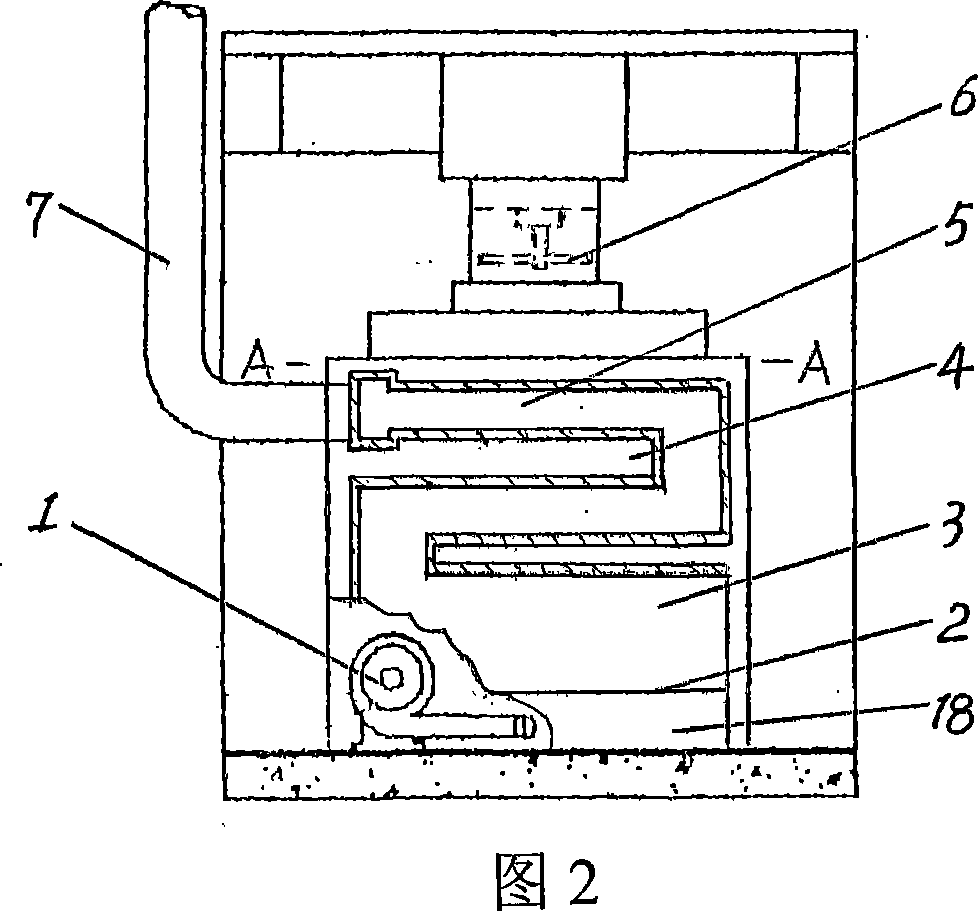

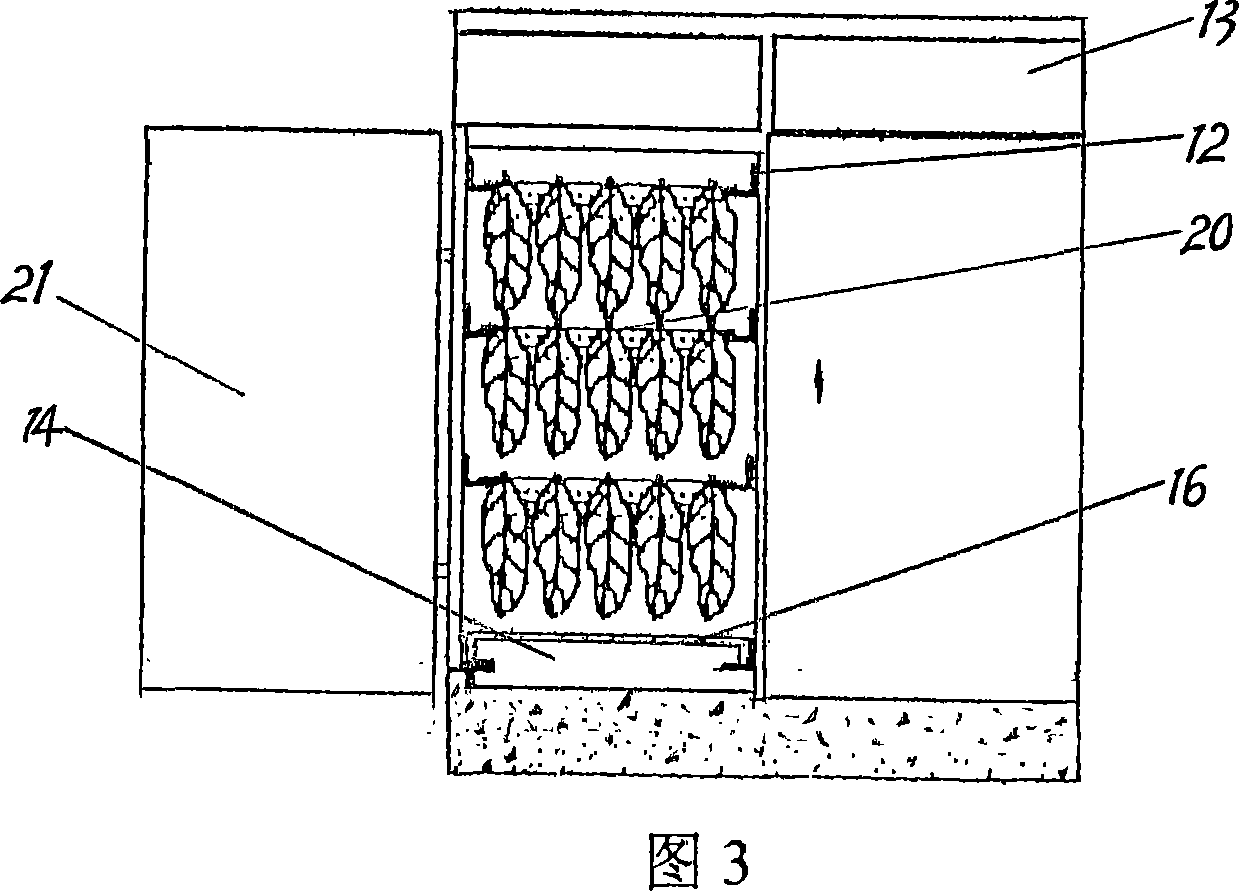

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] The coal-fired stove 3 is provided with a grate 2, and the bottom of the grate 2 is provided with an ash bin 18 and a tuyere 19, and the tuyere 19 is connected with the blower 1, so as to provide combustion-supporting air for combustion in the stove 3 as required. Above the stove 3 is Heat exchanger 4, a flue gas pipe 5 is arranged inside the heat exchanger 4, one end of the flue gas pipe 5 communicates with the stove 3, and the other end of the flue gas pipe 5 communicates with the chimney 7, so that the flue gas generated by the combustion of the stove 3 enters the smoke The gas pipe 5, after heat exchange with the air outside the flue gas pipe, is discharged from the chimney 7, the top of the heat exchanger 4 is provided with a fan 6 and an air inlet 8, and the bottom is provided with a hot gas outlet 17, so that the air enters the heat exchanger 4 The hot ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com