Preparation method of methyl ethylamine

A technology for methylethylamine and formylethylamide, which is applied in the field of preparation of methylethylamine, can solve problems such as being unsuitable for industrial production, and achieve the effects of simple and easy-to-obtain starting materials, stable and controllable quality, and simple and easy reaction operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

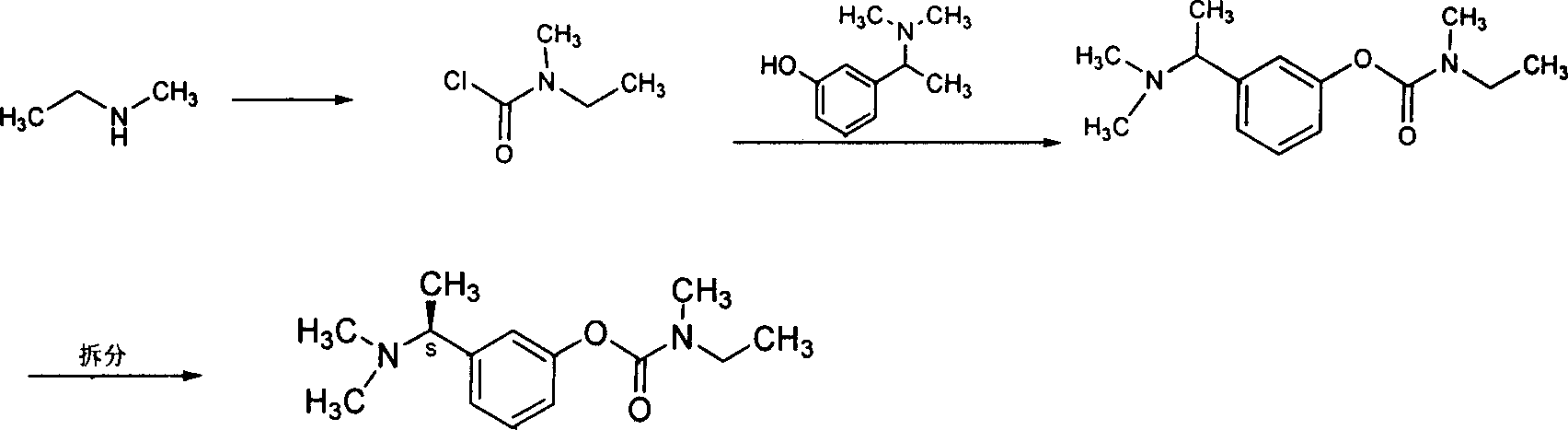

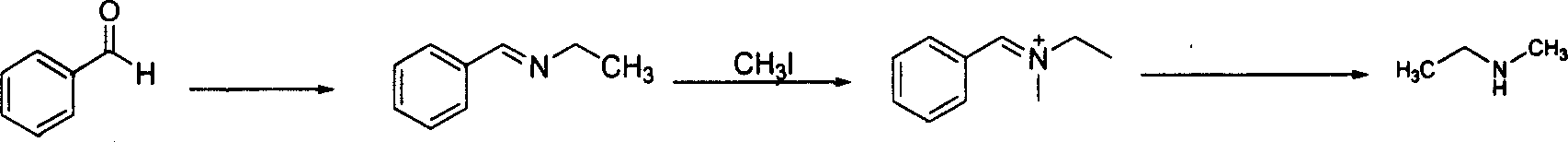

Method used

Image

Examples

Embodiment 1

[0020] Embodiment one: the preparation of formyl ethylamide

[0021] Add 7.5 L of methyl formate to the reaction kettle and cool to about 0°C. Maintaining less than 10°C, add 650g of ethylamine dropwise. After the dropwise addition was completed, the mixture was slowly heated to reflux for 4 hours. After the reaction was completed, the reaction solution was concentrated. Add toluene and concentrate under reduced pressure 250 mL x 3 times to obtain light yellow oil. equimolar yield.

Embodiment 2

[0022] Embodiment two: the preparation of formyl ethylamide

[0023] 15 L of ethyl formate was added to the reaction kettle. Maintain a solution of 1300 g of ethylamine in 1.5 L of ethanol dropwise at less than 10 ° C. After the dropwise addition was completed, the reaction was carried out at room temperature for 20 hours. After the reaction was completed, the reaction solution was concentrated. Add toluene and concentrate under reduced pressure 500 mL x 3 times to obtain light yellow oil with equimolar yield.

Embodiment 3

[0024] Embodiment three: the preparation of formyl ethylamide

[0025] Add 1.5 L of ethyl formate to the reaction kettle and cool to about 0°C. Maintain a solution of 1300 g of ethylamine in 1.5 L of ethanol dropwise at less than 10 ° C. After the dropwise addition was completed, the mixture was heated to reflux for 4 hours. After the reaction was completed, the reaction solution was concentrated. Add toluene and concentrate under reduced pressure 500 mL x 3 times to obtain light yellow oil with equimolar yield.

[0026] Embodiment two: the preparation of methylethylamine

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com