High efficiency chilled high intensification piston of diesel engine

A diesel engine and piston technology, which is applied in the field of high-strength diesel engine pistons, can solve the problems of affecting the cooling effect, misalignment, and obstruction of lubricating oil flowing into the oil chamber, so as to improve the oil supply efficiency, ensure the working reliability, and improve the cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

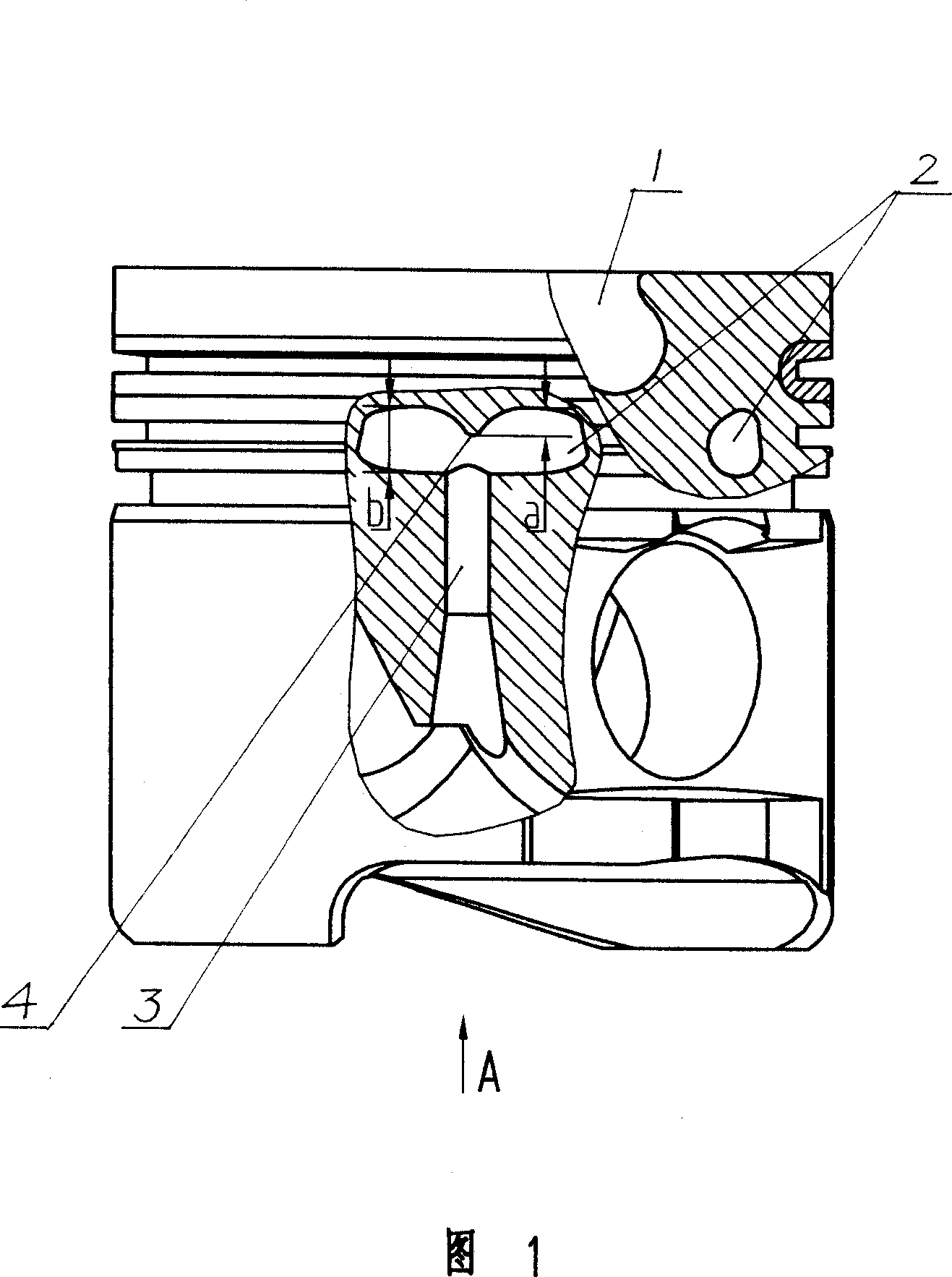

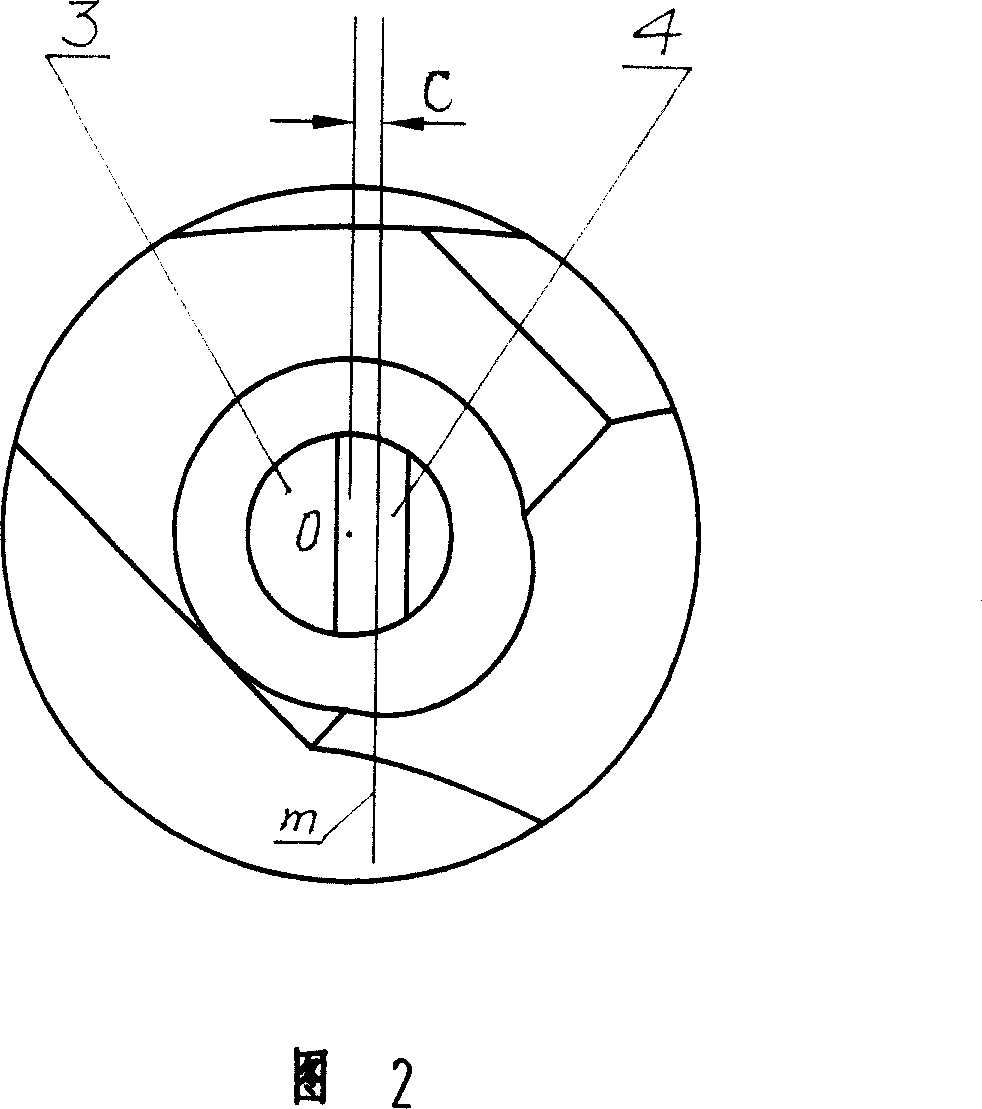

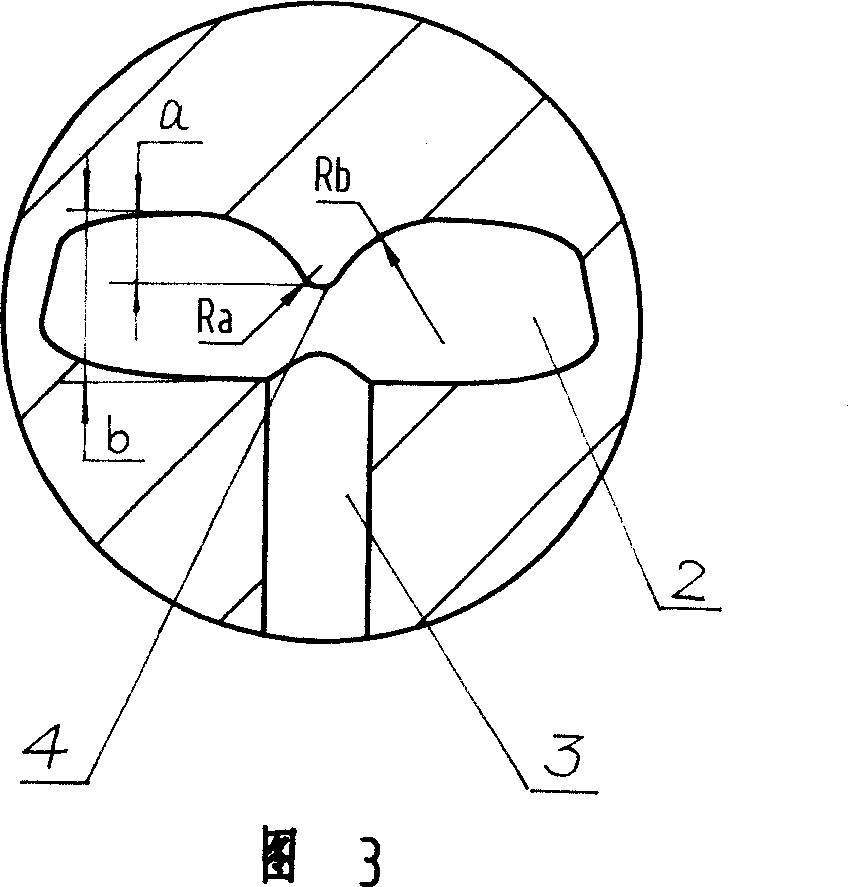

[0013] Example 1: Referring to Figures 1, 2, and 3, the high-efficiency cooling high-strength diesel engine piston has an annular internal cooling oil chamber 2 located below the combustion chamber 1, and one side of the bottom of the piston has an axial shaft communicating with the internal cooling oil chamber. There is an oil inlet hole 3 and an oil return hole on the other side. In the inner cooling oil chamber facing the oil inlet hole, there is a shunt protrusion 4 along the radial direction of the piston. The fillet radius Ra of the shunt protrusion is 1.5mm. The height a of the convex point is 1 / 4 times of the height b of the oil cavity. The two sides of the cross section of the convex point are arc lines, and the radius Rb of the arc is 10mm. The center of the convex point ridge area is the center of the rounded corner of the convex point. The straight line m where the projected line segment of the line segment is relative to the piston top plane deviates from the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com