Dispensing system for alkali metals capable of releasing a high quantity of metals

A distribution system, alkali metal technology, applied in the direction of distribution device, special distribution device, metal material coating process, etc., can solve the problems of increasing the temperature of quartz crystal, losing the precision of processing control, and the interference of deposit thickness measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

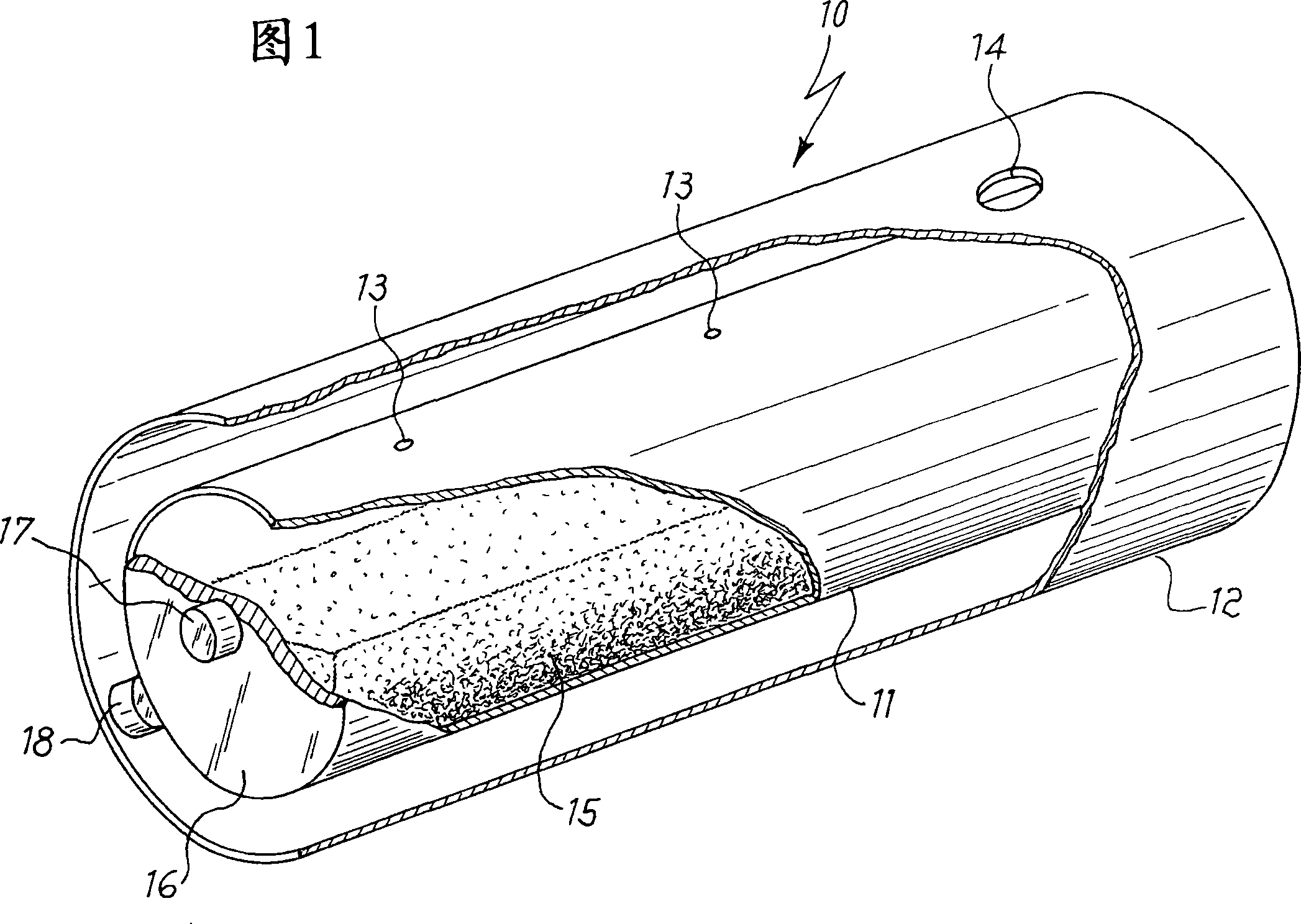

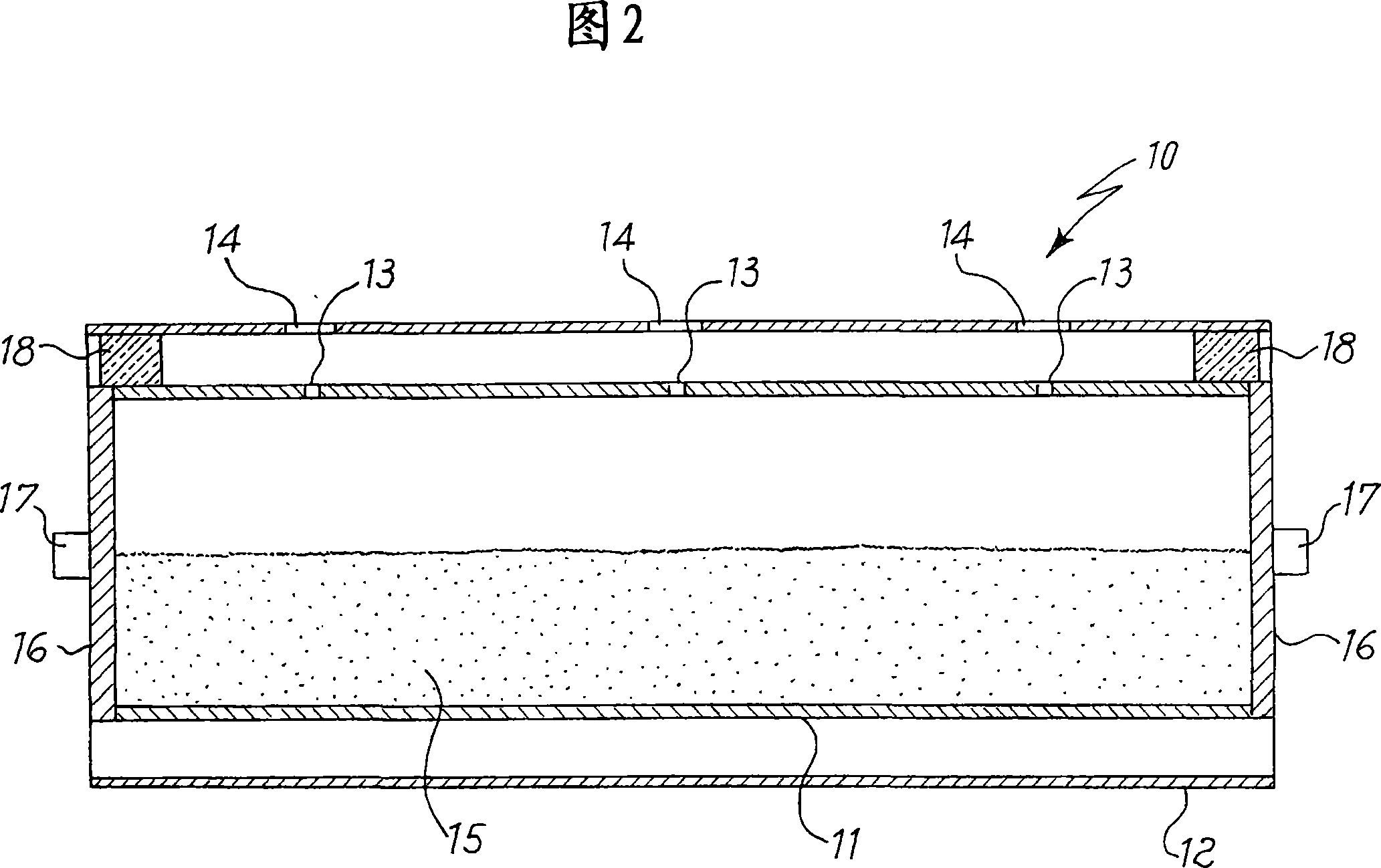

[0016] The containers of the present invention may have any shape. For example, the container may have an elongated shape with a trapezoidal cross-section (this shape is also known in the art as a "boat"), with extensions at the ends specifically for connecting electrical terminals for heating; containers of this type For example, it has been described in the applicant's patent US6753648. In this case, the shield surrounds at least the larger surface of the container, possibly with openings corresponding to said extensions at the ends of the container; the shield is shaped such that at least between the first and second openings In the area, the distance between the container and the shielding body is as small as possible, which is compatible with the requirements of easy manufacturing, emptying the formed space and avoiding contact between the container and the shielding body caused by thermal deformation, which is described below will be discussed in detail.

[0017] One o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com