Method for compensating round angle of metal bump for semiconductor chip electric contact

A technology of metal bumps and compensation methods, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as corner deformation into rounded corners, and achieve the effects of quality improvement, easy implementation, and improved front appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

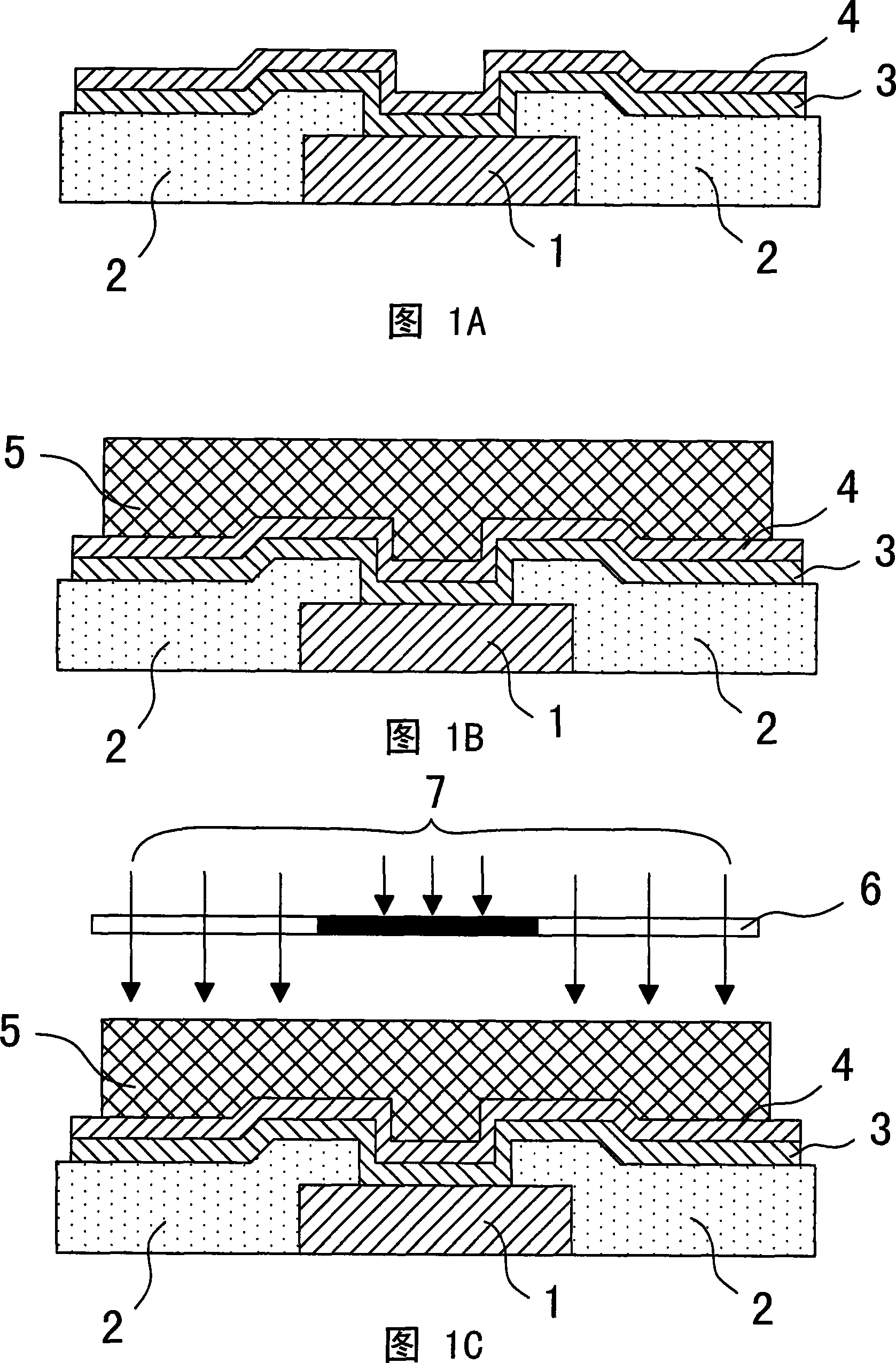

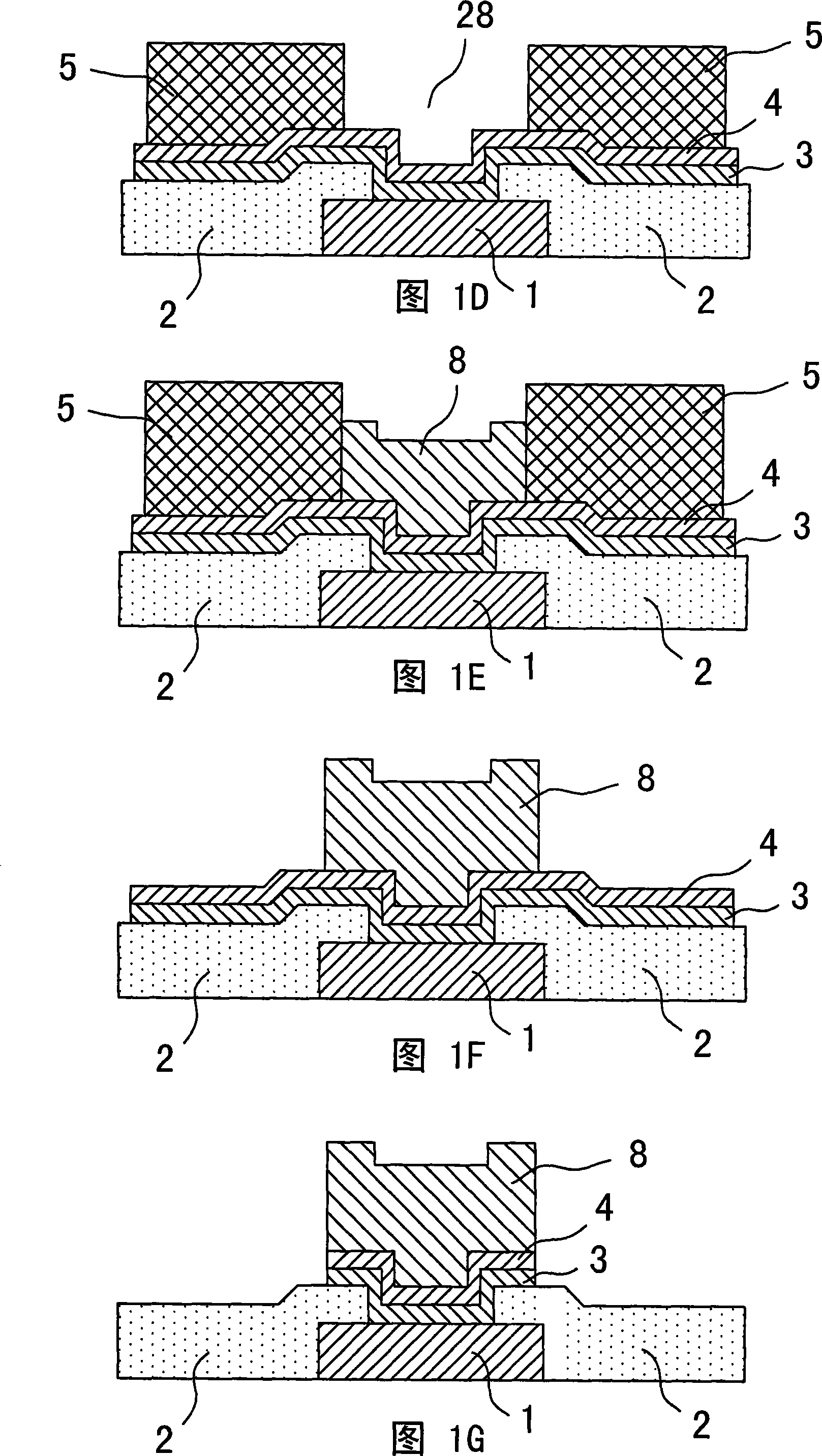

Method used

Image

Examples

Embodiment 1

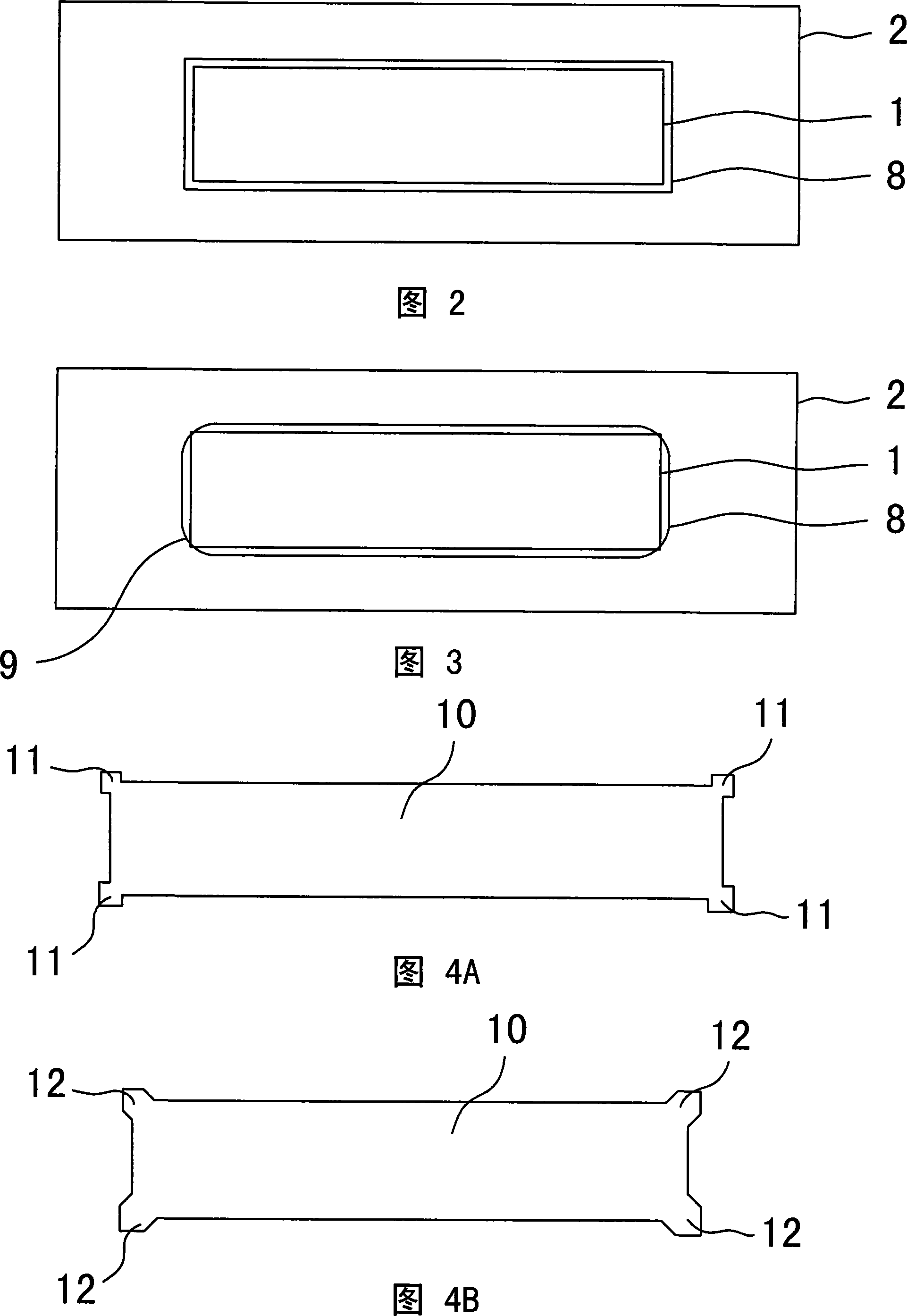

[0056] Embodiment 1: A method for rounding corner compensation of a rectangular gold bump. During the manufacturing process of a rectangular gold bump combined with photolithography and electroplating, the four theoretically designed corners of the bump pattern on the mask are turned outward Extend and increase the size of the window to make up for the defects caused by insufficient developer replenishment during the development process, that is, the inward shrinkage deformation produces rounded corners, so as to ensure that the corners of the actually produced gold bumps are right angles. There are four types of specific implementation methods:

[0057] 1. As shown in FIG. 4A, in the mask design, the four right angles of the rectangular gold bump pane 10 are partially enlarged in proportion, and the compensation angle 11 is extended to the outside to increase the window size. The shape is shown in Figure 4A. The compensation angle 11 is still a right angle. Fig. 4B is anoth...

Embodiment 2

[0063] Embodiment 2: A method for round corner compensation of a prismatic gold bump, and the specific implementation methods include the following four types:

[0064] 1. As shown in FIG. 8 , in the mask design, the two acute angles of the prismatic gold bump pane 16 are partially enlarged proportionally, and the compensation angle 17 is extended outward to increase the window size. The two obtuse angles are partially enlarged in proportion, and a compensation angle 18 is extended to the outside to increase the size of the window.

[0065] 2. As shown in Figure 9, in the mask design, the two acute angles of the prismatic gold bump pane 16 are partially expanded outwards, and the compensation angle 19 is extended outwards to increase the size of the window, and the compensation angle 19 The angle is smaller than the theoretical design angle. The two obtuse angles adopt the method of local expansion to the outside, and extend the compensation angle 20 to the outside to increas...

Embodiment 3

[0068] Embodiment 3: As shown in FIG. 12 , a method for round corner compensation of a right-angled triangular gold bump, in the mask design, a right angle of the right-angled triangle pane 25 is partially enlarged in proportion to extend outward The compensation angle 26 increases the size of the window, and the compensation angle 26 is still a right angle. The two acute angles are locally enlarged in proportion, and the compensation angle 27 is extended to the outside to increase the size of the window. The angle of the compensation angle 27 is equal to the theoretical design angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com