Apparatus and process for forming low-pressure and large-capacity digital-controlled extruding pouring plastic

A forming equipment and large-capacity technology, which is applied in the field of low-pressure and large-capacity CNC extrusion plastic injection molding equipment and forming technology, can solve the problems of high equipment cost, demanding processing capacity, range and material requirements, and long investment recovery period. Simple structure, convenient extrusion capacity, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

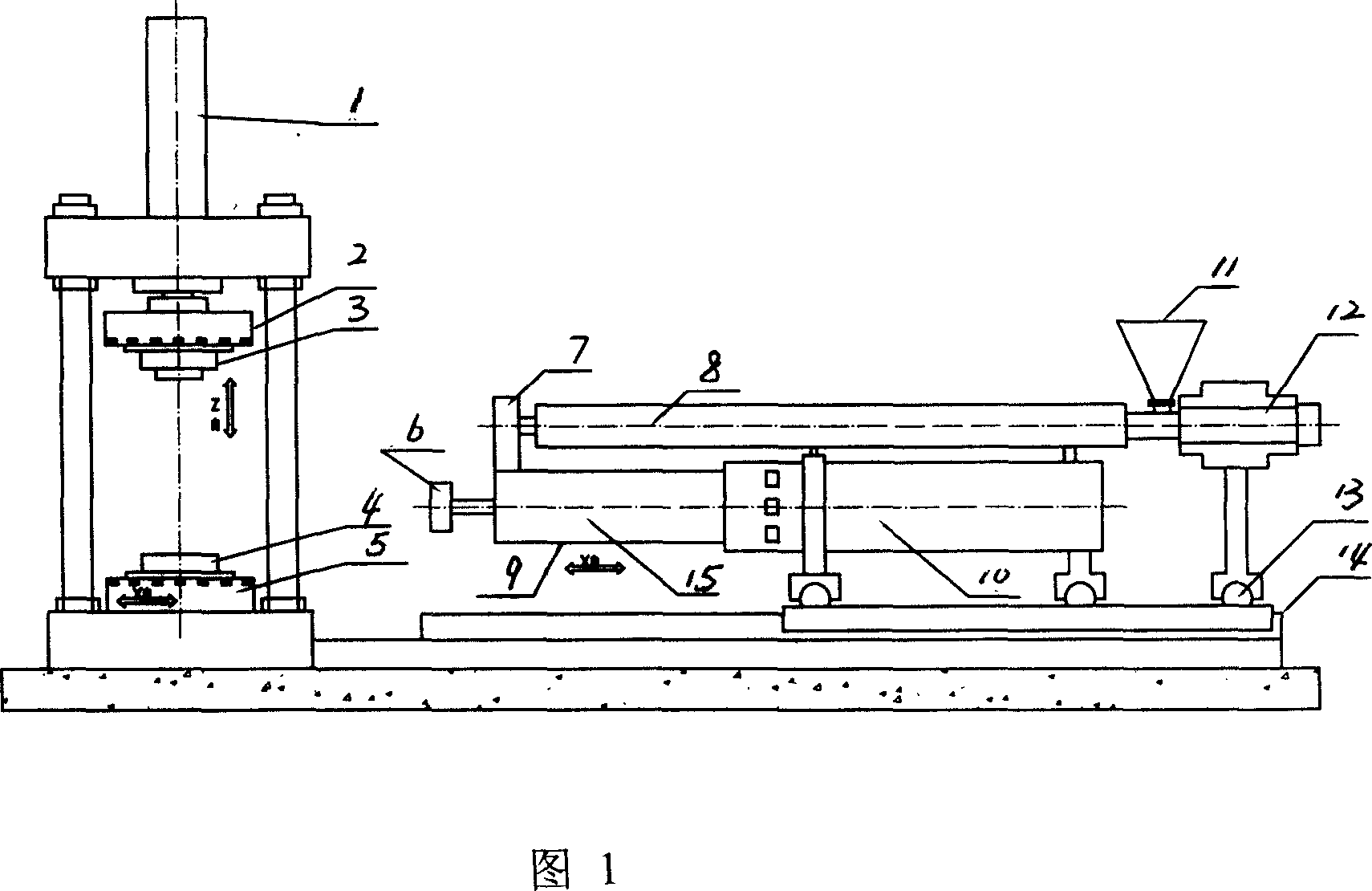

[0009] Embodiment 1: with reference to accompanying drawing 1. Low-pressure and large-capacity CNC extrusion plastic molding equipment, which includes a vertical mold clamping mechanism, the material storage extrusion cylinder 9 is processed and manufactured according to the existing technology and installed on rails 14 and 13 that can be moved by CNC in the X and Y horizontal directions. Material extrusion cylinder 9 is composed of nozzle valve 6, material storage cylinder 15 and extrusion oil cylinder 10. The piston in extrusion oil cylinder 10 and the inner wall of material storage cylinder 15 form a piston structure. Nozzle valve 6 communicates with the outlet of material storage cylinder 15. . The plasticizing screw 8 is processed and manufactured according to the prior art and is located on the material storage extrusion cylinder 9 and communicates with the storage material extrusion cylinder 9 through the valve 7. The screw in the plasticization screw 8 is a single-scre...

Embodiment 2

[0010] Example 2: Low-pressure and large-capacity CNC extrusion plastic injection molding process. Plastic enters the screw from the hopper, and after being plasticized by the plasticizing screw, it enters the storage tank through the valve through the screw rotation. After the storage is completed, the storage is squeezed out of the cylinder. The nozzle valve moves to the top of the mold cavity of the lower mold in the vertical mold clamping mechanism, and the oil cylinder pushes its piston to squeeze the material in the storage cylinder into the mold cavity quantitatively through the nozzle valve according to the instructions of the digital control system, and then exit the storage material extrusion Out of the cylinder, the upper and lower molds in the vertical mold clamping mechanism clamp and maintain pressure, and at the same time enter the next cycle of material storage. After the pressure is maintained, the mold is opened, and the manipulator enters the cavity to take ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com