Synthesis of densified siloxate ceramic by liquified polysiloxane

A technology of liquid polysiloxane and hydrogen polysiloxane, which is applied in the field of liquid polysiloxane to synthesize dense silicon carbon ceramics, can solve problems such as complex process and sample cracking, and achieve simple and controllable process, easy preparation, The effect of easy control of the shape of the ceramic body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

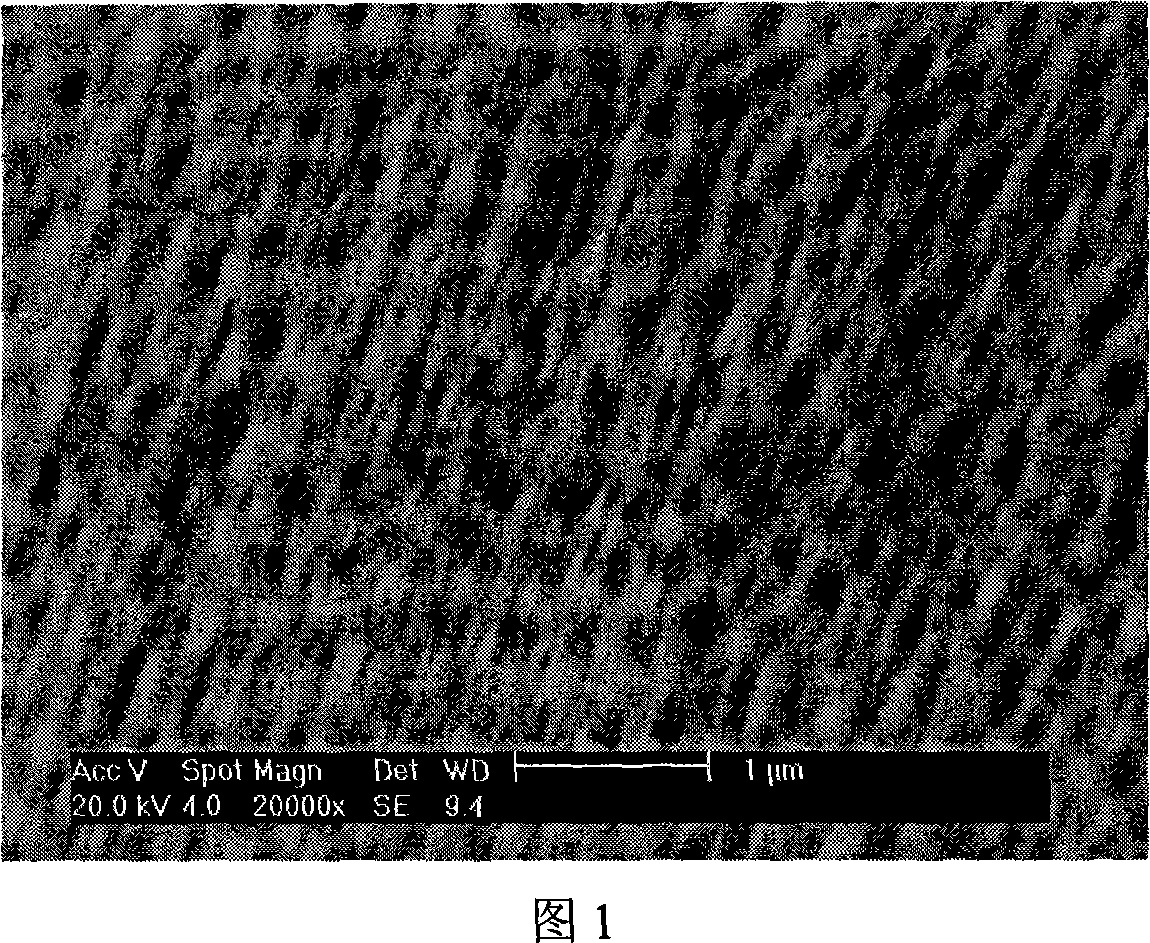

[0019] Using 10g of hydrogen-containing polysiloxane and 10g of tetramethyltetravinylcyclotetrasiloxane with magnetic stirring, add 0.2g of vinylsiloxane platinum complex catalyst dropwise, mix well and pour into the mold, at 20 Place it at ℃ for 48 hours to form a cross-linked body, then place it at 80℃ for 6 hours and then demould directly to prepare a green body with a circular diameter of 2.3cm. Under the protection of an argon atmosphere, the heating rate is raised to 1000 ℃, after holding for 1h, the temperature was lowered to 20℃ at a cooling rate of 2℃ / min to obtain dense SiOC amorphous ceramics. The cross-sectional appearance of this ceramic is shown in accompanying drawing 1.

Embodiment 2

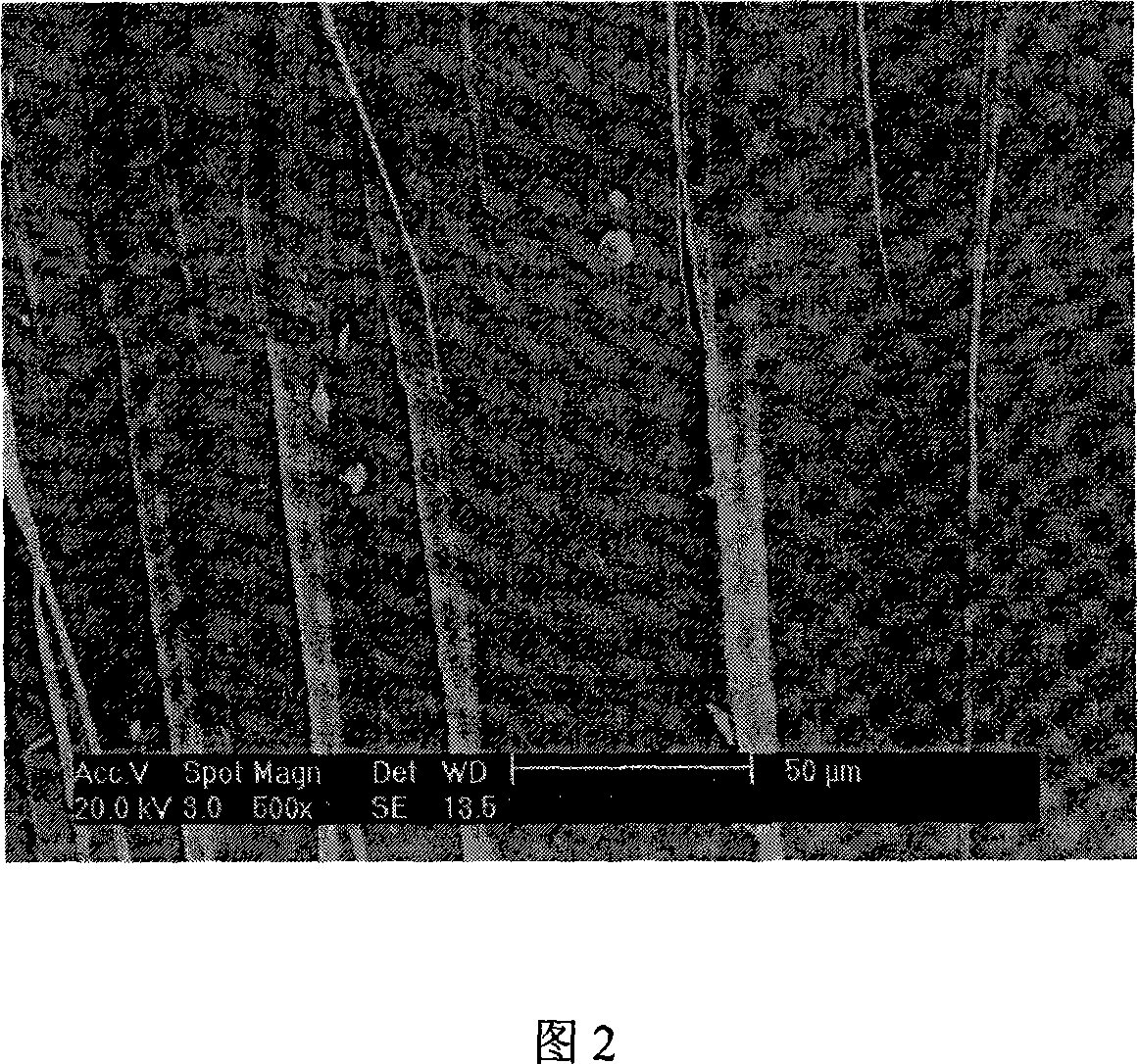

[0021] Adopt 10g of hydrogen-containing polysiloxane and 5g of tetramethyltetravinyl cyclotetrasiloxane, while stirring magnetically, add 0.15g of vinylsiloxane platinum complex catalyst dropwise, mix well and pour into the mold Preliminarily form a cross-linked body at 50°C, and then place it at 100°C for 6 hours after demoulding, then raise the temperature to 800°C at a heating rate of 1°C / min in a nitrogen atmosphere, and then cool down to 800°C at a cooling rate of 2°C / min after holding for 2 hours. At 20°C, dense silicon-oxycarbon-carbon amorphous ceramics were obtained. The cross-sectional appearance of this ceramic is shown in accompanying drawing 2.

Embodiment 3

[0023] Adopt 5g of hydrogen-containing polysiloxane and 10g of tetramethyltetravinylcyclotetrasiloxane, while stirring magnetically, add 0.15g of vinylsiloxane platinum complex catalyst dropwise, mix well and pour into the mold Place at 80°C for 6 hours, dry and remove the mold, in a nitrogen atmosphere, increase the temperature at a rate of 2°C / min to 1000°C, and after holding for 4 hours, lower the temperature to 20°C at a rate of 2°C / min to obtain dense SiOC amorphous ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com