Process for freezing and crystallizing triformol continuouslly by sleeved crystallizer

A technology of paraformaldehyde and freeze crystallization, which is applied in the field of freeze crystallization of paraformaldehyde, can solve the problems of increased adsorption, high content of fine crystals, system paralysis, etc., and achieves improved heat transfer capacity, large specific surface area, and increased capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

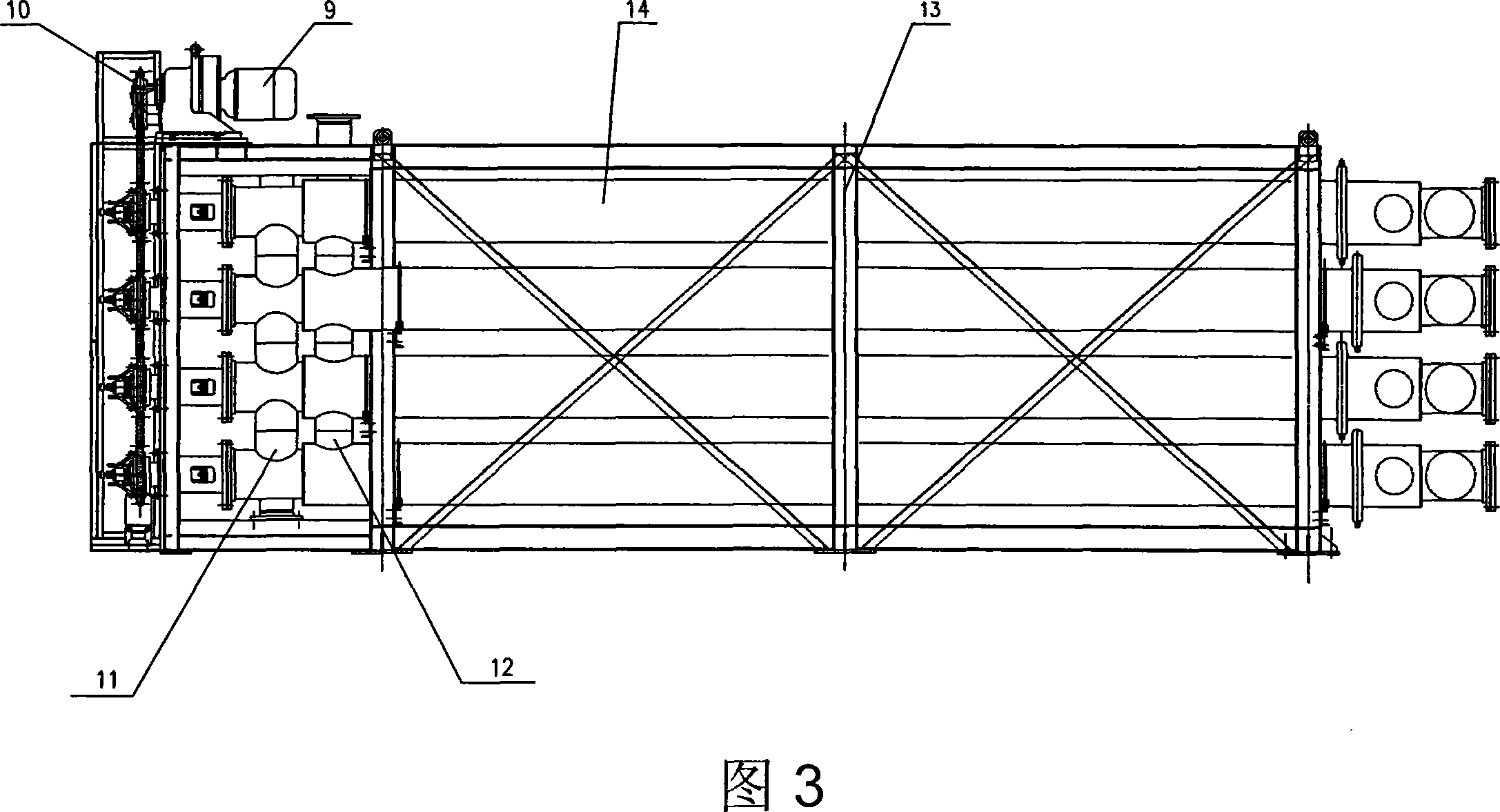

[0028] The specific structure of the process of the present invention and the sleeve-type crystallizer used in the process will be further described below in conjunction with the accompanying drawings. The following examples take the polyoxymethylene plant with an annual output of 10,000 tons as the basis for selecting equipment and process parameters.

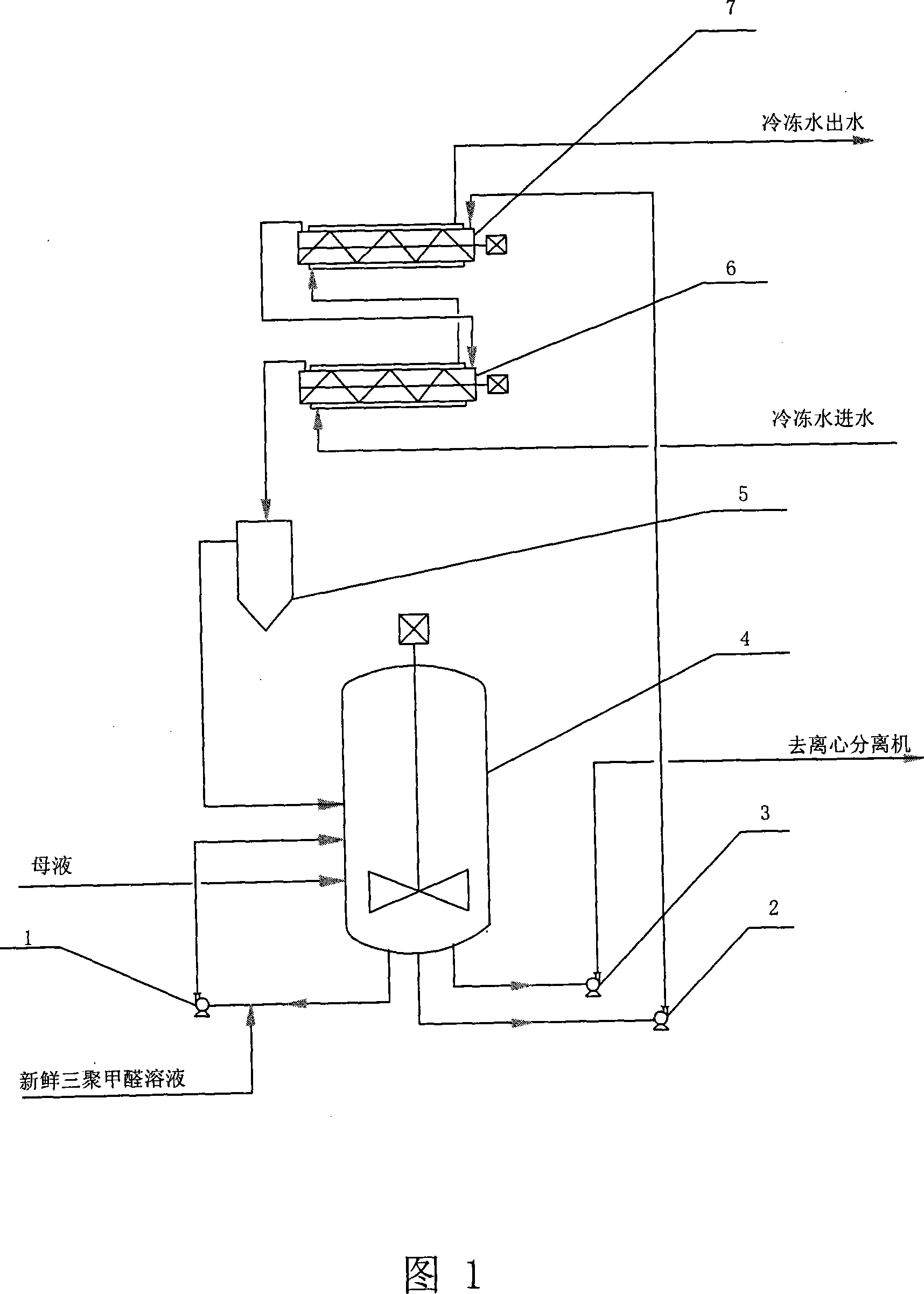

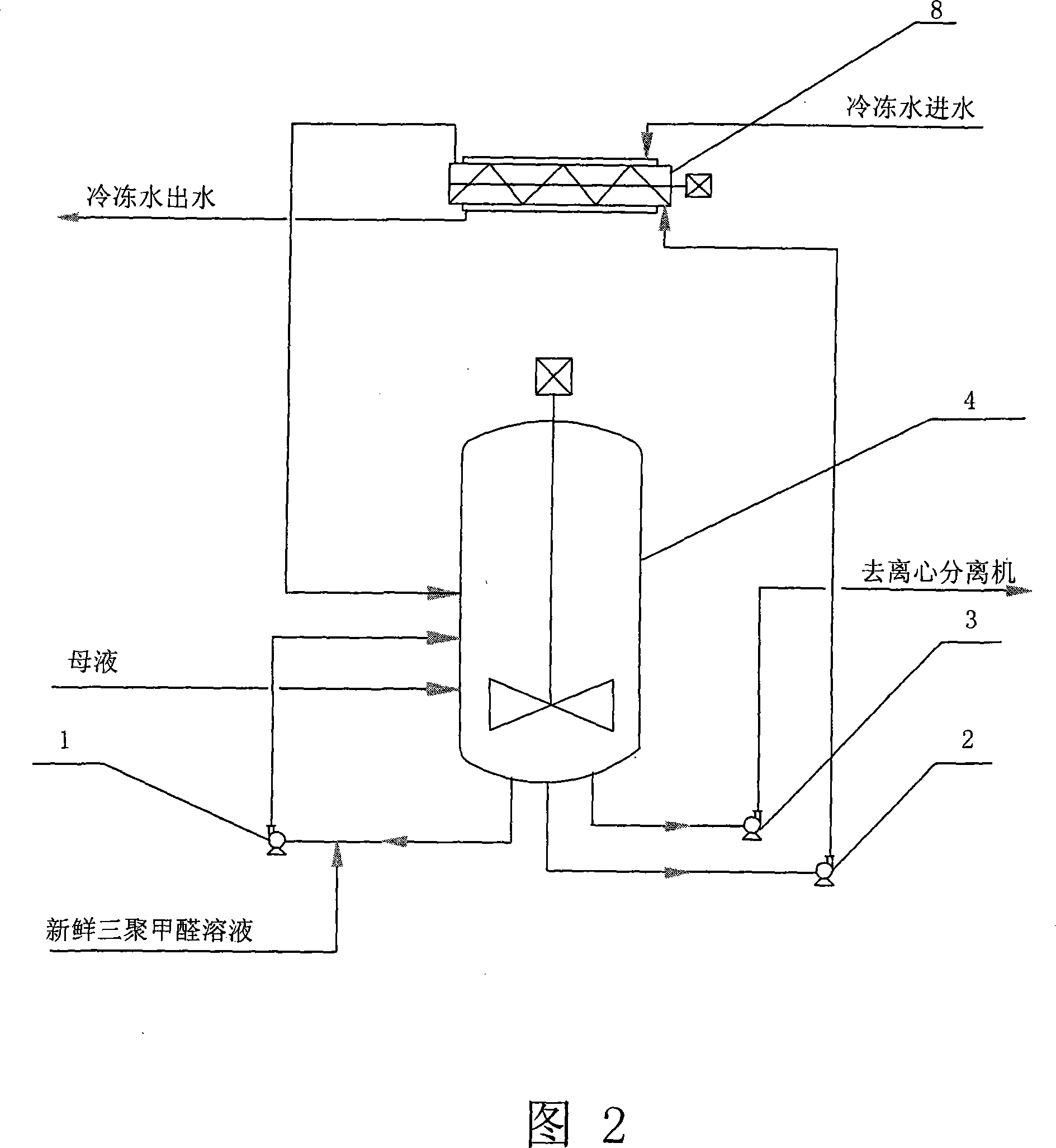

[0029] The process flow of this embodiment is as shown in Figure 1: the fresh paraformaldehyde solution from the front system enters the circulating loop formed by the circulation pump I1, the rear crystallizer 4 and the connecting pipe fittings and mixes with the paraformaldehyde suspension; in the rear crystallizer 4 Part of the paraformaldehyde suspension is transported by the ring pump II2 to the casing type crystallizer 8 for heat exchange with chilled water to form a paraformaldehyde crystal nucleus, and the paraformaldehyde suspension after the heat exchange is returned to the rear crystallizer 4 for trimerization The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com