Filter-pressing process for producing malt extract during production of beer

A production process and wort technology, applied in the field of automatic diaphragm wort filter press, can solve the problems of difficulty in ensuring levelness, affecting the effect of filtration, increasing manufacturing difficulty, etc. The effect of running elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

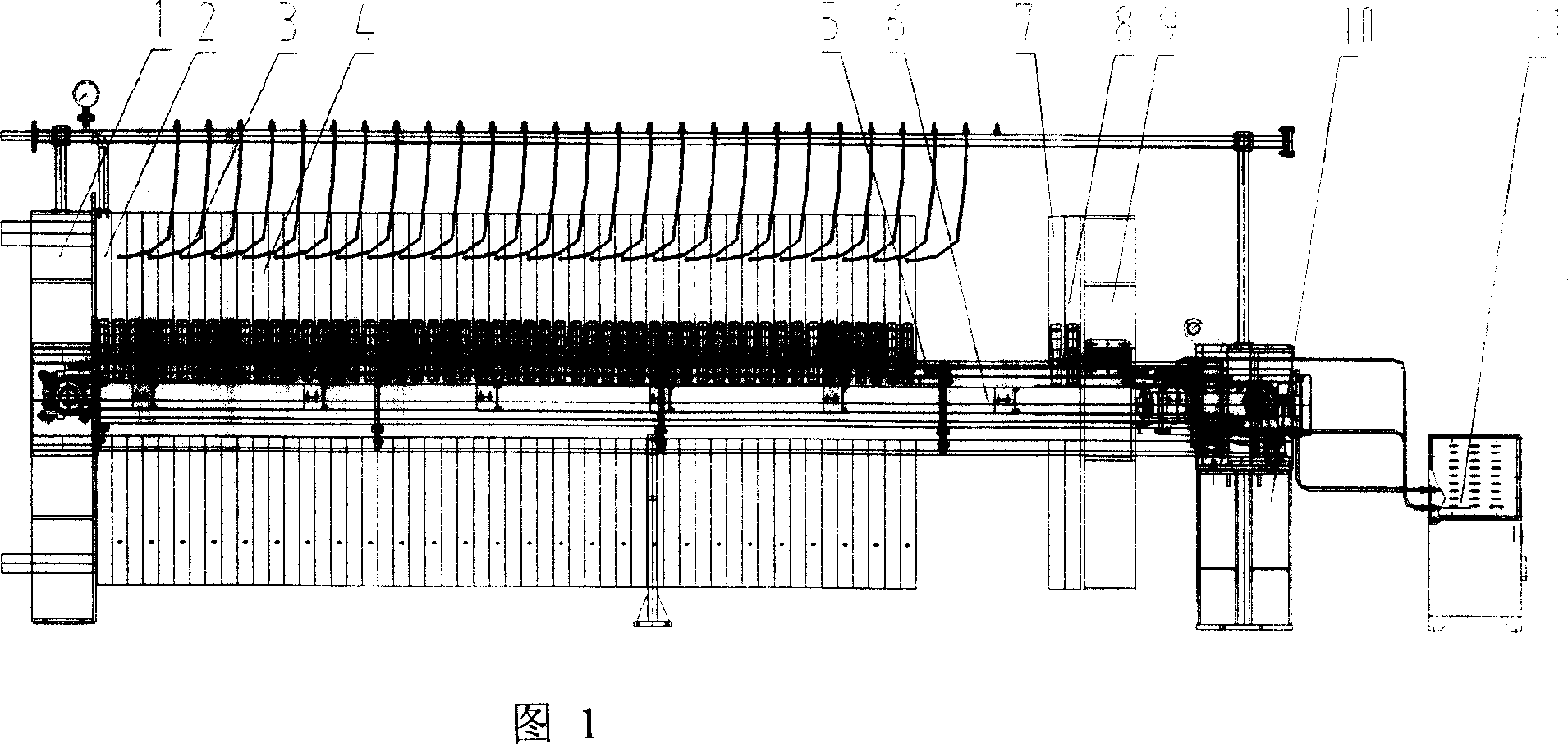

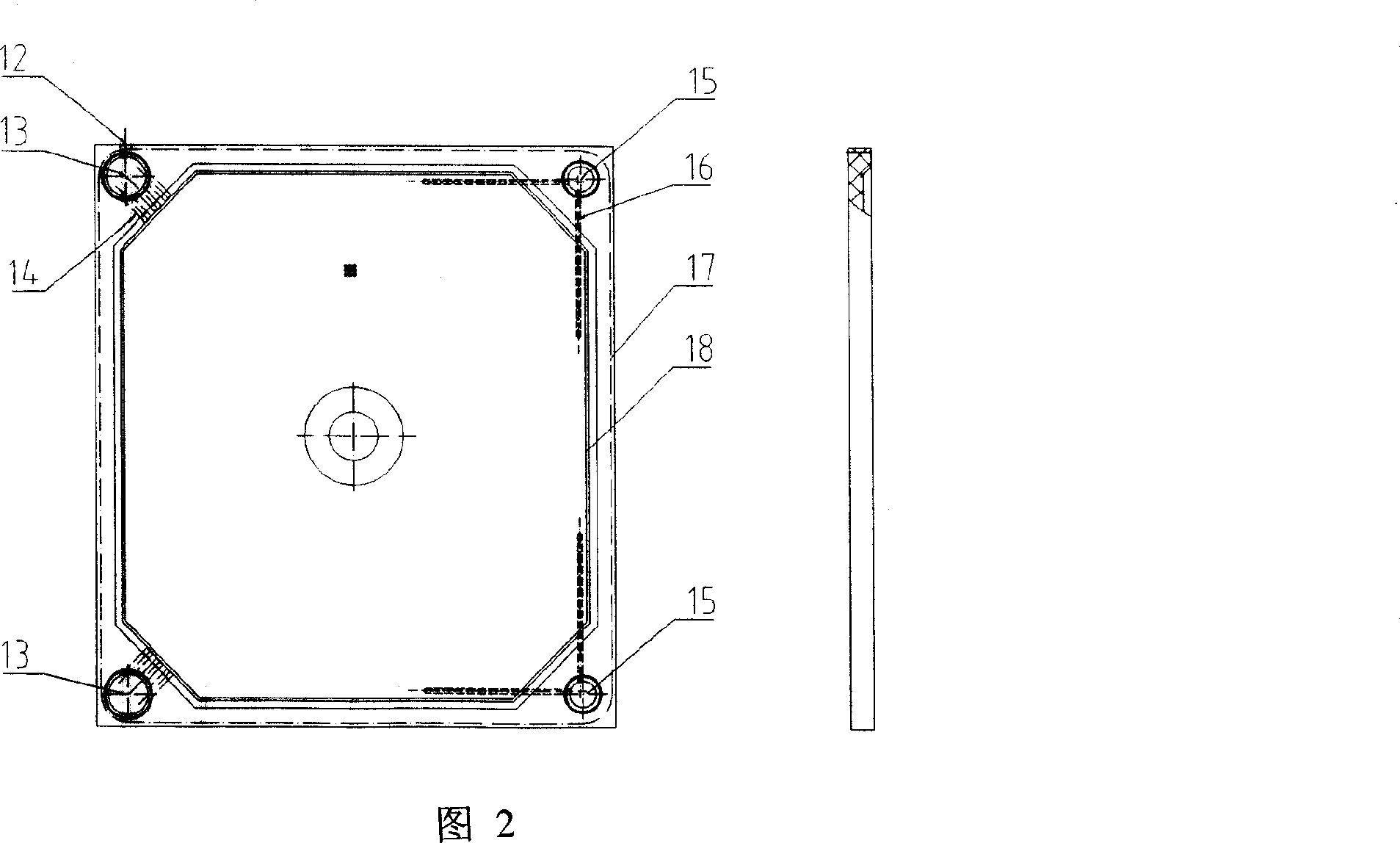

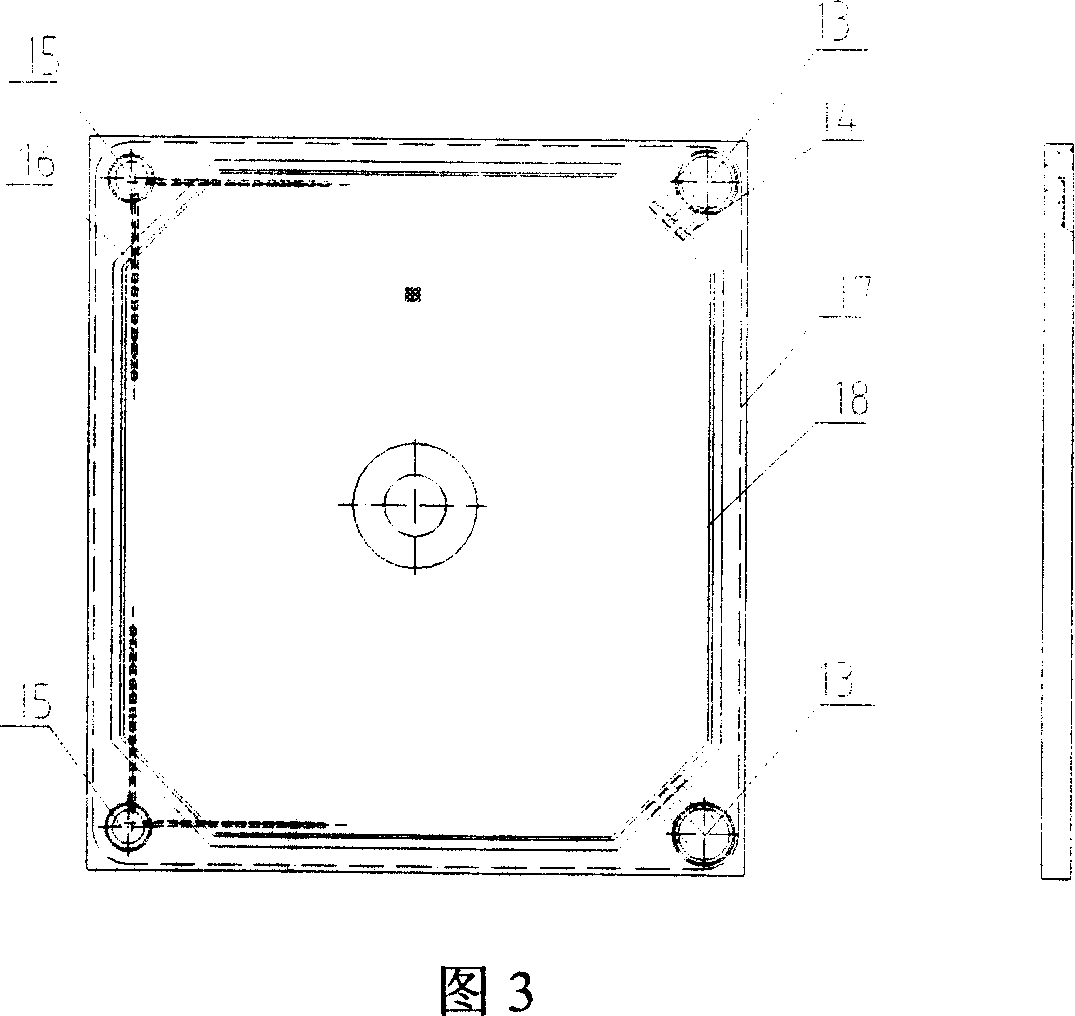

[0018]Embodiment 1: with reference to accompanying drawing 1~6. Fully automatic diaphragm wort filter press, which includes a frame part, a filter part, a pull plate part, a hydraulic part and an electrical control part. The frame part is mainly composed of a thrust plate 1, a compression plate 9, an oil cylinder seat 10 and a main beam 6 etc. parts are formed, and its manufacturing process is prior art, does not describe here. The filter part is composed of the filter plate 4, the diaphragm plate 3 and the filter cloth arranged on the main beam in a certain order. The filter plates and the diaphragm plates are arranged alternately to form several independent filter units—filter chambers. A sealing surface O-ring 17 is embedded around the filter plate 4 between the thrust plate 1 and the pressing plate 9, and the sealing surface contacts between the filter plate and the diaphragm plate. The automatic plate-drawing mechanism part is made up of hydraulic motor, manipulator 5, t...

Embodiment 2

[0020] Embodiment 2: On the basis of embodiment 1, the pressure filtration process of producing wort by mash mash in the beer production process, (1) close the wort filter press, and the hydraulic system automatically compresses the pressure plate and maintains it automatically At a certain pressure level, the filter press enters the state of automatic pressure maintenance; 1) The hydraulic system automatically compresses the pressure plate and maintains it within the pressure range of 15MPa-18MPa, and the entire filter press is in a closed state; (2) Hot water Quickly inject the mash into the filter press through the pump and pass through the feed hole to preheat the filter plate of the filter press to prevent the temperature from decreasing and the viscosity increasing when the mash enters the filter press. At the same time, the mash entering the filter press does not mix with Air contact to avoid oxygen absorption of wort; (3) The mash is quickly filled into the filter press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com