Integrated corn processing

A technology of corn and corn syrup, which is applied in the petroleum industry, lighting and heating equipment, combustion methods, etc., and can solve problems such as energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

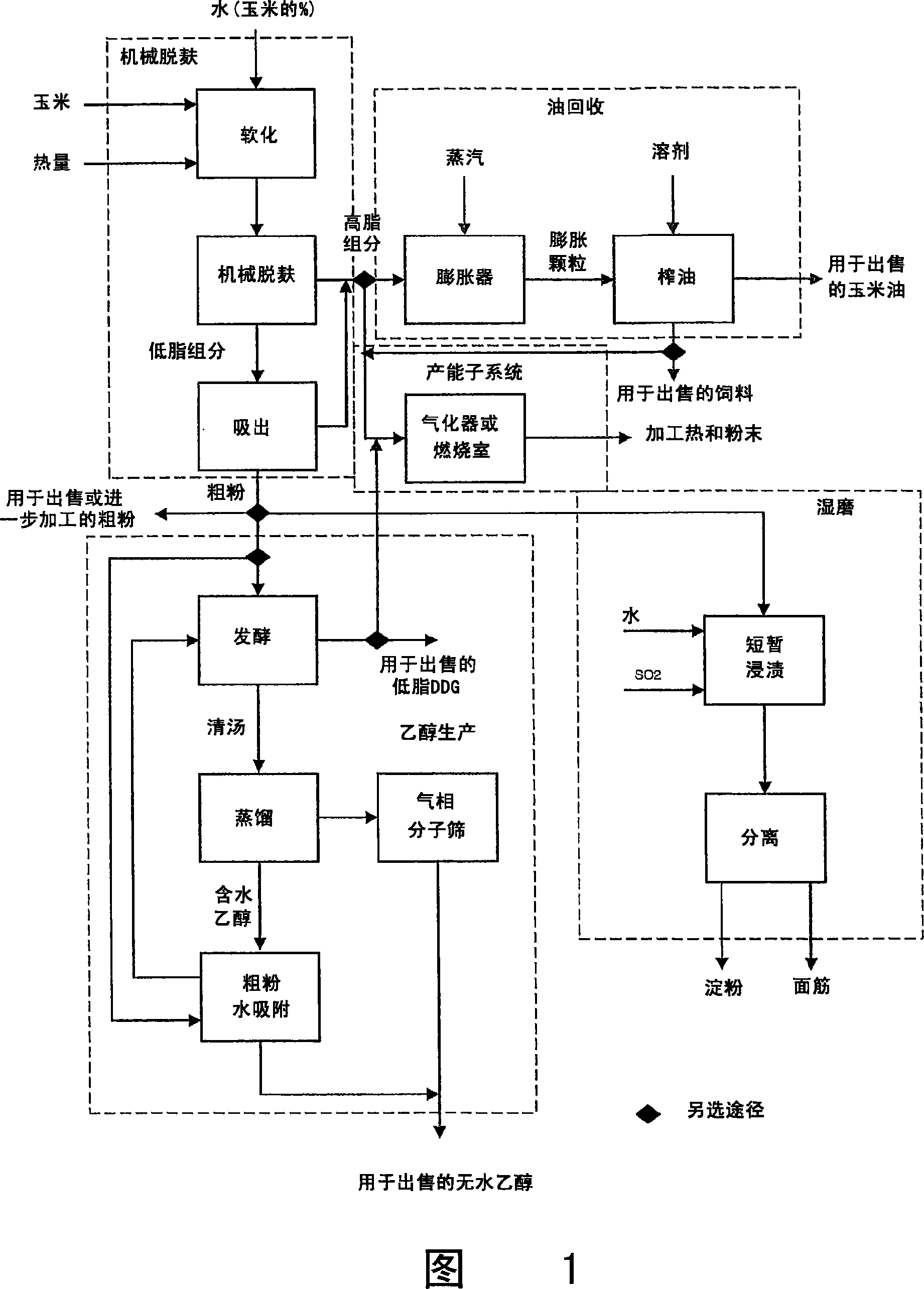

Image

Examples

Embodiment I

[0064] Example I - Separation

[0065] The basic steps for separating high-oil corn from low-oil corn HOF and LOF, or HSF and LSF are basically the same. The specific examples provided below are for high oil corn.

[0066] High Oil Corn Kernel 1 (LH310 (Inbred, Holdens Foundation Seeeds) x HOI 001) stored in a blade mixer with a steam jacket was metered, see U.S. Patent Publication Nos. 2003 / 018269 and 2003 / 0172416, incorporated herein by reference. Reference) and High Oil Corn Kernel 2 (Top Cross Blend seed corn, purchased in spring 2003, harvested in fall 2003, Indiana), with a retention time of about 7 minutes. Heat at 90°F to soften the corn. The softened corn is then sent to a Buhler-L unit (Buhler GmbH, Germany) where the hulls and softer tissues are ground into a low oil fraction ("LOF") and mixed with a high oil fraction ("HOF") separate. The analysis results of grain, HOF and LOF are shown in Table I-1.

[0067] moisture

[0068] These results show th...

Embodiment II

[0069] Embodiment II-oil extraction

[0070] A. High oil corn

[0071] Expanded collets were produced by HOF expansion of yellow dent variety #2 corn with a DFEA-220 expander (Buhler GmbH, Germany). Moisture is added to the expansion tank in the form of steam. The rate of steam addition was 6.0-6.8%. Cooling the expanded HOF in a horizontal ambient air cooler reduced the moisture content to 10.13-12.45%. The HOF expands to make it suitable for delivery to a full scale solvent extractor.

[0072] A full-scale extraction process was performed on two truck loads of expanded HOF with 23-32% HOF in the truck. The remainder is wet milled pressed germ cake. It takes 3.5 hours to unload the load from the wagons into the wet-milled germ stream. The mixture was pressed using a shallow bed Crown III oil press. The processing capacity of the oil press is 1000T / day.

[0073] The table below shows the results at different sampling points during the experiment:

[0074] F...

Embodiment IV

[0111] US Patent Nos. 6,313,328 and 6,388,110 describe an industrial scale process for processing whole corn kernels having a total oil content of at least about 8% by weight comprising the steps of chipping the kernels and extracting the corn oil from the kernel chips. US Patent No. 6,610,867 describes a method of extracting corn oil to form corn meal. The method generally includes the steps of: crushing whole corn kernels having a total oil content of about 3-30% by weight, and extracting corn oil from the crushed kernels. (This method does not use slices). The extraction step is performed on all fractions of the whole kernel (in any form), including fractions with a low oil content. In contrast, the fractionation process of existing methods produces a high oil component and a low oil component. The low-oil component avoids the oil extraction process and can be directly fed or used for other applications. Only the high oil fraction is pressed and extracted. This process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com