Combined oil shale dry distillation gas chemical chain hydrogen producing and power generating system and process

A combined power generation and oil shale technology, applied in inorganic chemistry, petroleum industry, special form of dry distillation, etc., can solve problems such as waste of resources, low energy efficiency, and poor economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

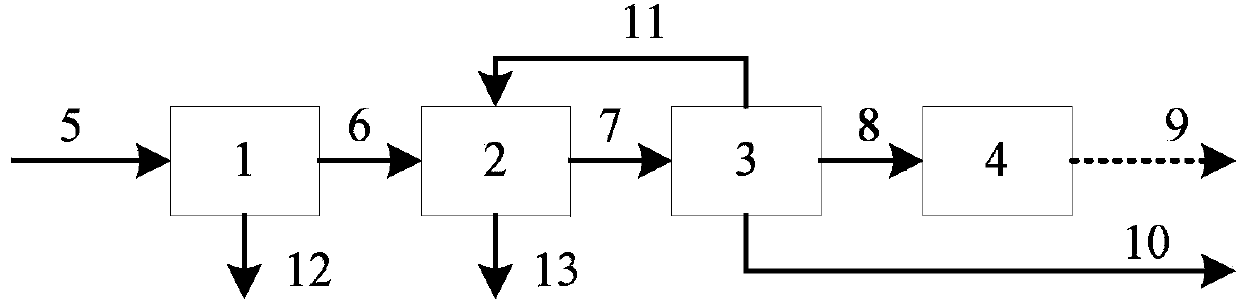

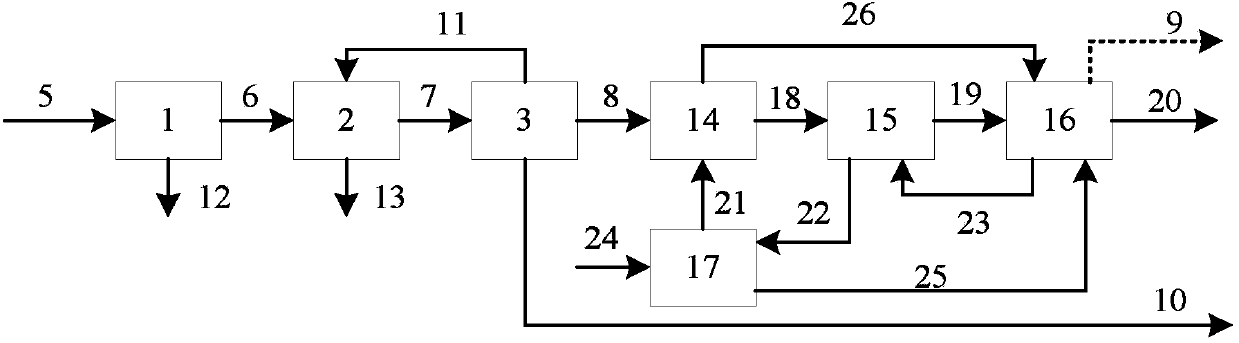

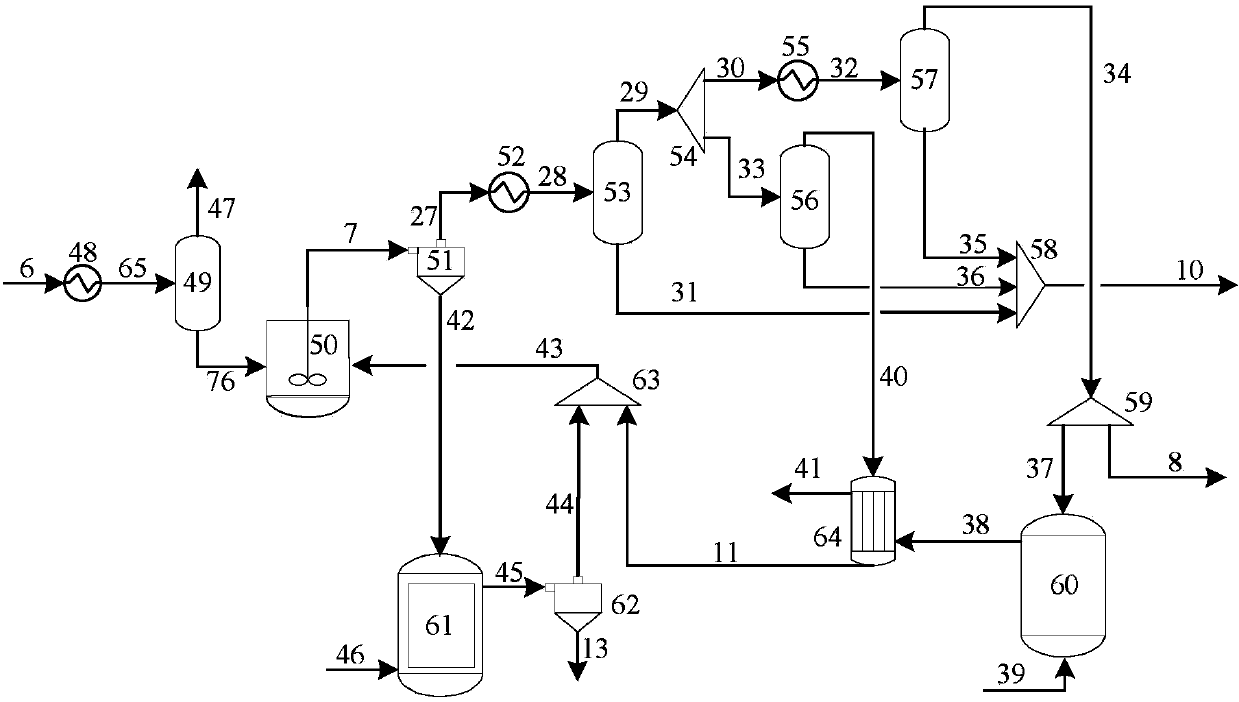

Method used

Image

Examples

Embodiment 1

[0095] The specific implementation of the oil shale and associated coal comprehensive utilization technology of the present embodiment is as follows:

[0096] The flow rate of oil shale raw materials entering the process of the present invention is 375t / h, of which 300t / h enters the oil shale carbonization unit, and the flow rate of clastic shale is 75t / h. The mass ratio of air to water vapor in the feed to the gasification reactor 61 of the oil shale carbonization unit 2 is 1.13. The industrial analysis and elemental analysis of oil shale raw materials are shown in Table 1. The process flow chart of oil shale dry distillation gas chemical chain hydrogen production combined power generation is shown in figure 2 .

[0097] Table 1 Elemental analysis of industrial analysis of oil shale raw materials

[0098]

[0099] (M, FC, V, and A in the table represent the contents of water, fixed carbon, volatile matter and ash in oil shale respectively, ar represents the received ba...

Embodiment 2

[0111] The specific implementation of the oil shale and associated coal comprehensive utilization technology of the present embodiment is as follows:

[0112] The flow rate of oil shale raw materials entering the process of the present invention is 365t / h, of which 275t / h enters the oil shale carbonization unit, and the flow rate of clastic shale is 50t / h. The mass ratio of air to water vapor in the feed to the gasification reactor 61 of the oil shale carbonization unit 2 is 1.20. The industrial analysis and elemental analysis of oil shale raw materials are shown in Table 2. The process flow chart of oil shale dry distillation gas chemical chain hydrogen production combined power generation is shown in figure 2 .

[0113] Table 2 Elemental analysis of industrial analysis of oil shale raw materials

[0114]

[0115] (M, FC, V, and A in the table represent the contents of water, fixed carbon, volatile matter and ash in oil shale respectively, ar represents the received ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com