Abstraction of pilose antler releasing somatomedin (DEER GHRF) and preparation method thereof

A technology of deer antler and extract, which is applied in the field of deer antler extract rich in growth hormone releasing hormone, can solve the problems of not finding and extracting growth hormone releasing hormone, waste of resources, limiting dosage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, the pretreatment of deer antler

[0026] Take 0.5kg of fresh velvet antler, use a cryostat to cut the velvet antler into slices with a thickness of 1-2mm, then add an appropriate amount (200mL) of pre-cooled deionized water to pulverize with a homogenizer at 4°C, and perform the homogenization operation until homogenized End when no tissue clumps are visible in the pulp. The obtained product was centrifuged at 5000 revolutions per minute (rpm) for 20 minutes, and the supernatant was collected. Add 200 mL of pre-cooled deionized water to the centrifugal pellet, resuspend the pellet and centrifuge again at 5000 rpm for 20 minutes, and take the supernatant. Then, repeat the above resuspension and centrifugation process once, and take the supernatant. The supernatants obtained by each centrifugation were combined to obtain 580 mL of pretreated deer antler extract.

Embodiment 2

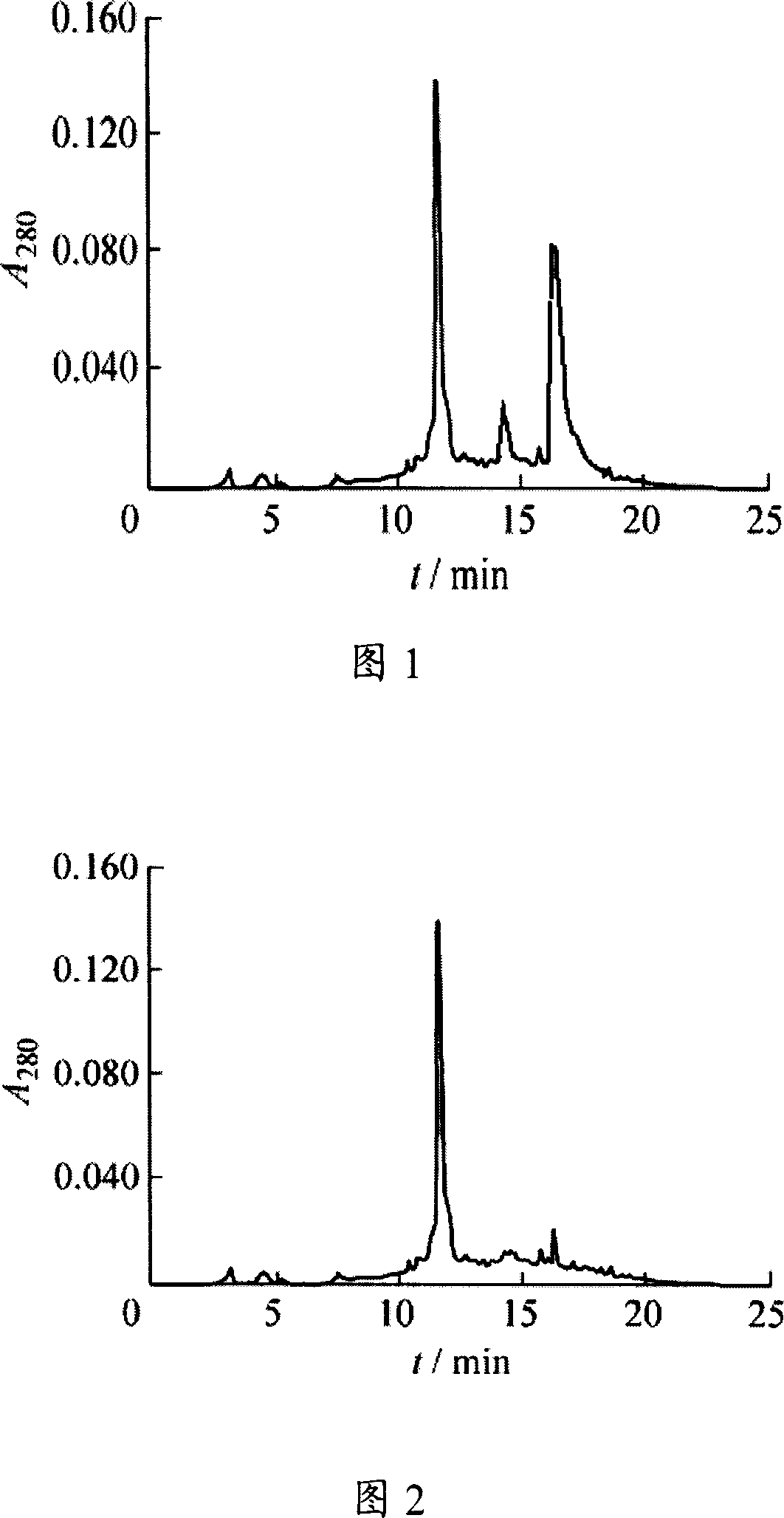

[0027] Embodiment 2, the chromatographic purification of velvet antler growth hormone releasing hormone and the preparation of its freeze-dried agent

[0028] Get the velvet antler extract that obtains in 580mL embodiment 1 and carry out 2 ultrafiltrations. An ultrafiltration membrane (purchased from Millopore, Ultrapore) with a molecular weight cut-off of 10 kDa was used for the first ultrafiltration, and the filtrate was retained. Then the filtrate was subjected to ultrafiltration with an ultrafiltration membrane with a molecular weight cut-off of 1 kDa (purchased from Millopore, Ultrapore), and the filtrate was discarded. Use 200mL pre-cooled deionized water to elute the substance retained by the ultrafiltration membrane, and keep the eluate for later use. Then the ultrafiltration membrane was eluted with 200 mL of pre-cooled deionized water, the ultrafiltration membrane was discarded, and the obtained two eluates were combined, put into a dialysis bag, and concentrated wi...

Embodiment 3

[0029] Embodiment 3, the detection of growth hormone releasing hormone

[0030] Antler GH-releasing hormone was detected according to "Molecular Cloning Test Guide" (Science Press, 2002) and the GHRH activity detection method of Velicelebi G et al. The biological activity of GHRH is detected by the ability of the primary cultured mouse anterior pituitary cells to secrete growth factors, by comparing with the GHRH standard substance (purchased from Bachem Company), adding the velvet antler growth hormone releasing hormone solution obtained in Example 2 In the experimental group, it has a good promoting effect on the ability of the primary cultured mouse anterior pituitary cells to secrete growth factors, reaching 96% of the activity of the GHRH standard product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com