Non-virus nano nucleic acid transferring composite for curing gristle defection by injecting in joint cavity and preparing method thereof

A complex, joint cavity technology, applied in the field of non-viral nano-nucleic acid transport complex and its preparation, can solve the problems of large molecular weight, limited application, high solution viscosity, etc., to increase water solubility, reduce viscosity, and enhance biocompatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

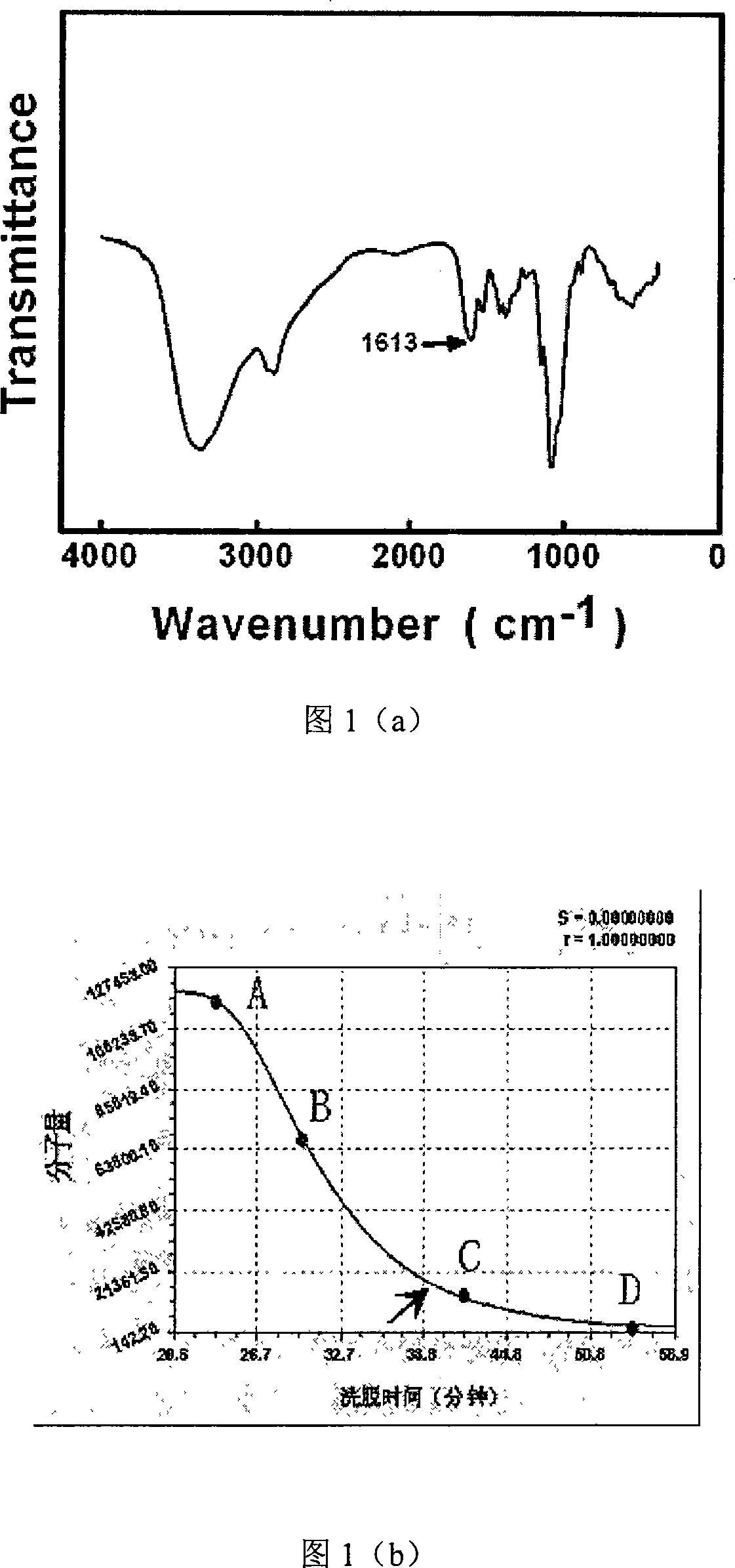

[0053] The preparation of embodiment 1 low molecular weight chitosan

[0054]Get 5g commercially available high molecular weight chitosan (St.Louis, MO, USA, molecular weight is about 150KDa, 85% deacetylation) in the 250ml round bottom flask, add the 4M HCl of 125ml, 100 ℃ of oil baths 15 hours, simultaneously Stir. After cooling, filter with double-layer lens-cleaning paper to obtain 85ml of solution, add an equal volume of absolute ethanol to the solution, mix well, and freeze overnight at 4°C. Then centrifuge at 10000rpm for 10 minutes and discard the supernatant. Add 50ml of 50% ethanol to the pellet to wash, resuspend, and centrifuge at 10000rpm for 10 minutes. Repeat the above washing, suspension and centrifugation process three times. The precipitate was dried, dissolved in 15 ml of double distilled water, and finally freeze-dried to obtain a white powdery solid, which was low molecular weight chitosan. The composition of the product was determined by elemental ana...

Embodiment 2

[0055] The preparation of embodiment 2 low molecular weight chitosan

[0056] Get 5g commercially available high molecular weight chitosan (St.Louis, MO, USA, molecular weight is about 150KDa, 85% deacetylation) in the 250ml round bottom flask, add the 4M HCl of 140ml, 100 ℃ of oil baths 25 hours, simultaneously Stir. After cooling, filter with double-layer lens-cleaning paper to obtain 90 ml of solution, add an equal volume of absolute ethanol to the solution, mix well, and freeze overnight at 4°C. Then centrifuge at 10000rpm for 10 minutes and discard the supernatant. Add 50ml of 50% ethanol to the pellet to wash, resuspend, and centrifuge at 10000rpm for 10 minutes. Repeat the above washing, suspension and centrifugation process three times. The precipitate was dried, dissolved in 15 ml of double distilled water, and finally freeze-dried to obtain a white powdery solid, which was low molecular weight chitosan. The composition of the product was determined by elemental a...

Embodiment 3

[0057] The preparation of embodiment 3 low molecular weight chitosan

[0058] Get 5g commercially available high molecular weight chitosan (St.Louis, MO, USA, molecular weight is about 150KDa, 85% deacetylation) in the 250ml round bottom flask, add the 4M HCl of 110ml, 100 ℃ of oil baths 10 hours, simultaneously Stir. After cooling, filter with double-layer lens-cleaning paper to obtain 90 ml of solution, add an equal volume of absolute ethanol to the solution, mix well, and freeze overnight at 4°C. Then centrifuge at 10000rpm for 10 minutes and discard the supernatant. Add 50ml of 50% ethanol to the pellet to wash, resuspend, and centrifuge at 10000rpm for 10 minutes. Repeat the above washing, suspension and centrifugation process three times. The precipitate was dried, dissolved in 15 ml of double distilled water, and finally freeze-dried to obtain a white powdery solid, which was low molecular weight chitosan. The composition of the product was determined by elemental a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com