Ultraviolet and high temperature aging resistant organic silicon epoxy resin composition used for luminescent diode encapsulation

A silicone epoxy resin, epoxy resin technology, applied in other chemical processes, chemical instruments and methods, electrical components and other directions, can solve the problems of low UV resistance and high temperature aging performance, and achieve excellent UV resistance and high temperature aging. performance, reduction of initial coloration or decrease in UV and high temperature aging resistance, effect of improved UV and high temperature aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

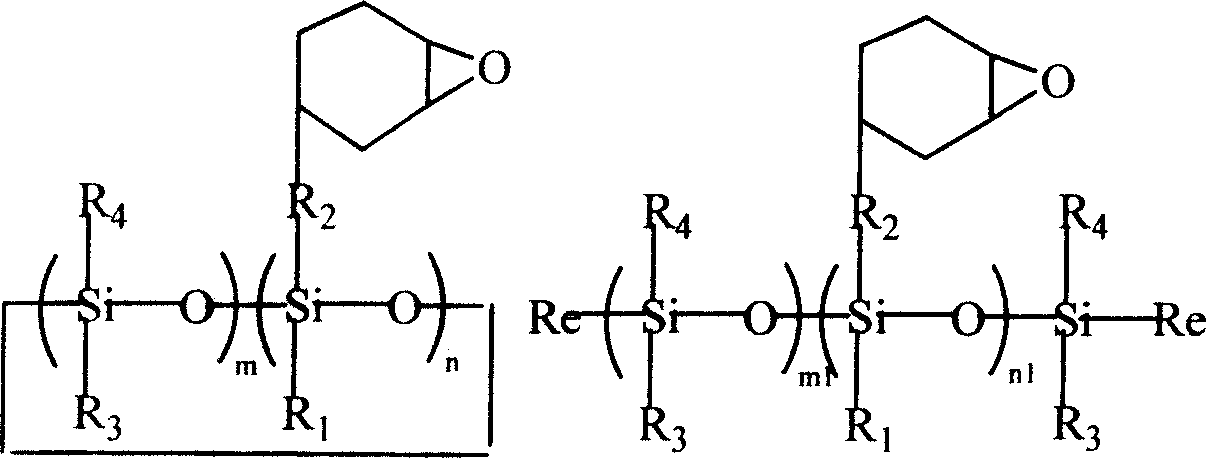

[0033] Embodiment 1: the synthesis of organosilicon epoxy resin A

[0034]24.8 grams (0.2 mol) of 4-vinylcyclohexyl 1,2 epoxy compound, 18.0 grams (0.075 mol) of tetramethyltetrahydrocyclotetrasiloxane, and 40 ml of toluene were added to a 300 ml three-necked flask. The temperature of the system is raised to 70-75° C., and 5-10 ppm (based on the total weight of the reactant) chloroplatinic acid catalyst is added to react for 5 hours. After completion of the reaction, 0.002 g of dimercaptobenzothiazole was added and stirred for 10 minutes. Then, the solvent and unreacted reactants were removed with a rotary evaporator at 2 mmHg / 80° C. to obtain 41.6 grams of colorless and transparent epoxy resin A, with a yield of about 97%.

Embodiment 2

[0035] Embodiment 2: the synthesis of silicone epoxy resin B

[0036] 24.8 grams (0.2 mol) of 4-vinylcyclohexyl 1,2 epoxy compound, 24.0 grams (0.1 mol) of tetramethyltetrahydrocyclotetrasiloxane, and 50 ml of toluene were added to a 300 ml three-necked flask. The temperature of the system is raised to 70-75° C., and 5-10 ppm (based on the total weight of the reactant) chloroplatinic acid catalyst is added to react for 5 hours. After completion of the reaction, 0.002 g of dimercaptobenzothiazole was added and stirred for 10 minutes. Then, the solvent and unreacted reactants were removed with a rotary evaporator at 2 mmHg / 80° C. to obtain 46.5 grams of colorless and transparent epoxy resin B, with a yield of about 95%.

Embodiment 3

[0037] Embodiment 3: the configuration of catalyst

[0038] Add 2g bisphenol A epoxy resin and 0.04g aluminum acetylacetonate to a 20ml beaker. Put the beaker in an oven at 120°C, take it out after the aluminum acetylacetonate is dissolved in the epoxy resin, and cool it down to room temperature for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com