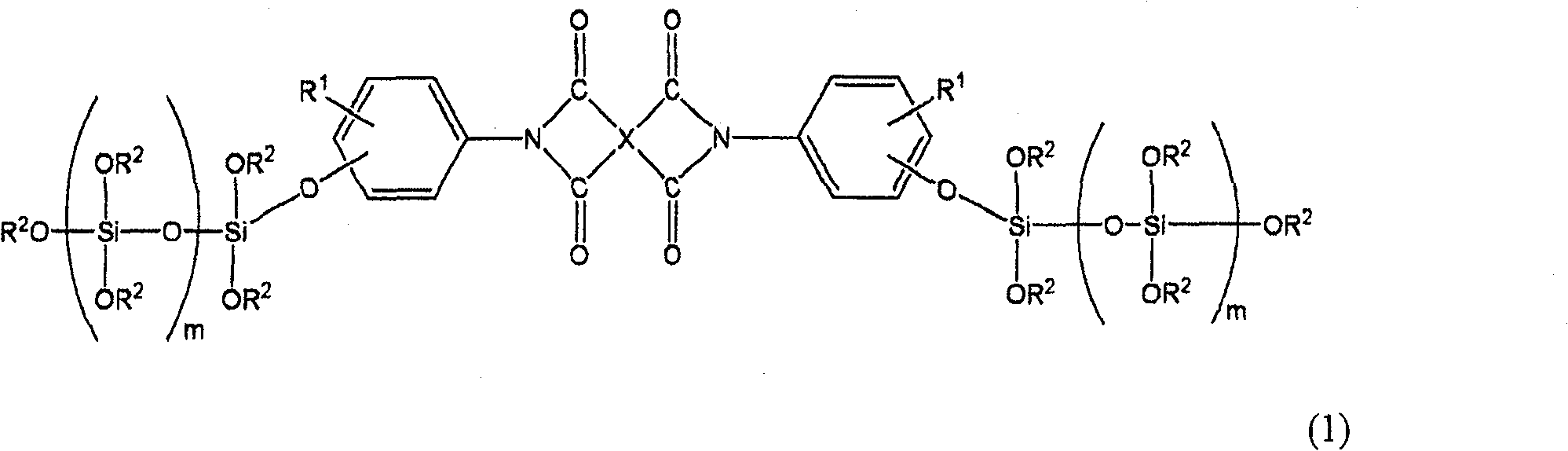

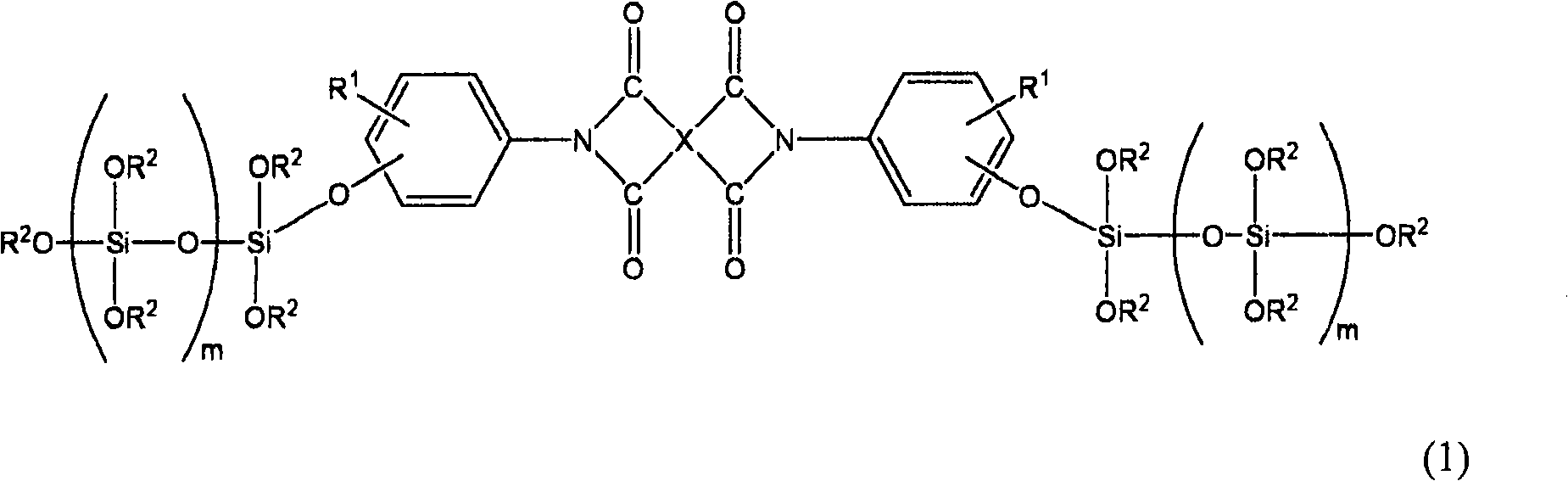

Resin composition based on polyimide siloxane

A technology of polyimide siloxane and resin composition, which is applied in the direction of coating, etc., can solve the problems of resin mechanical strength reduction, unsatisfactory solvent removal, and electrical performance degradation, and achieve the effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

[0143] Using the combinations and amounts (parts by mass) shown in Table 3 and Table 4 to mix the compositions comprising polyimidesiloxane and solvent prepared in Synthesis Examples 1-5 above, Synthesis Examples 6-8 above The methoxysilyl-containing bisimide compound prepared in , and tetraisopropoxytitanium as a condensation reaction catalyst: Ti(O-iPr) 4 , and the obtained mixture was thoroughly stirred, thus obtaining the polyimidesiloxane-based resin composition of the present invention.

[0144] Subsequently, the performance of each polyimidesiloxane-based resin composition of Examples 1-10 was evaluated using the following test.

[0145] [Adhesive strength measurement]

[0146] The polyimidesiloxane-based resin composition was applied to a glass substrate and left at 23° C. and 60% humidity for 72 hours to allow the solvent to evaporate, thus forming a tape with a size of 10 mm×150 mm and an average film thickness of 50 μm shape film.

[0147] The lengthwise tip of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com