Tensile and compressive stressed materials for semiconductors

A technology of stress materials and tensile stress, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, metal material coating technology, etc., and can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

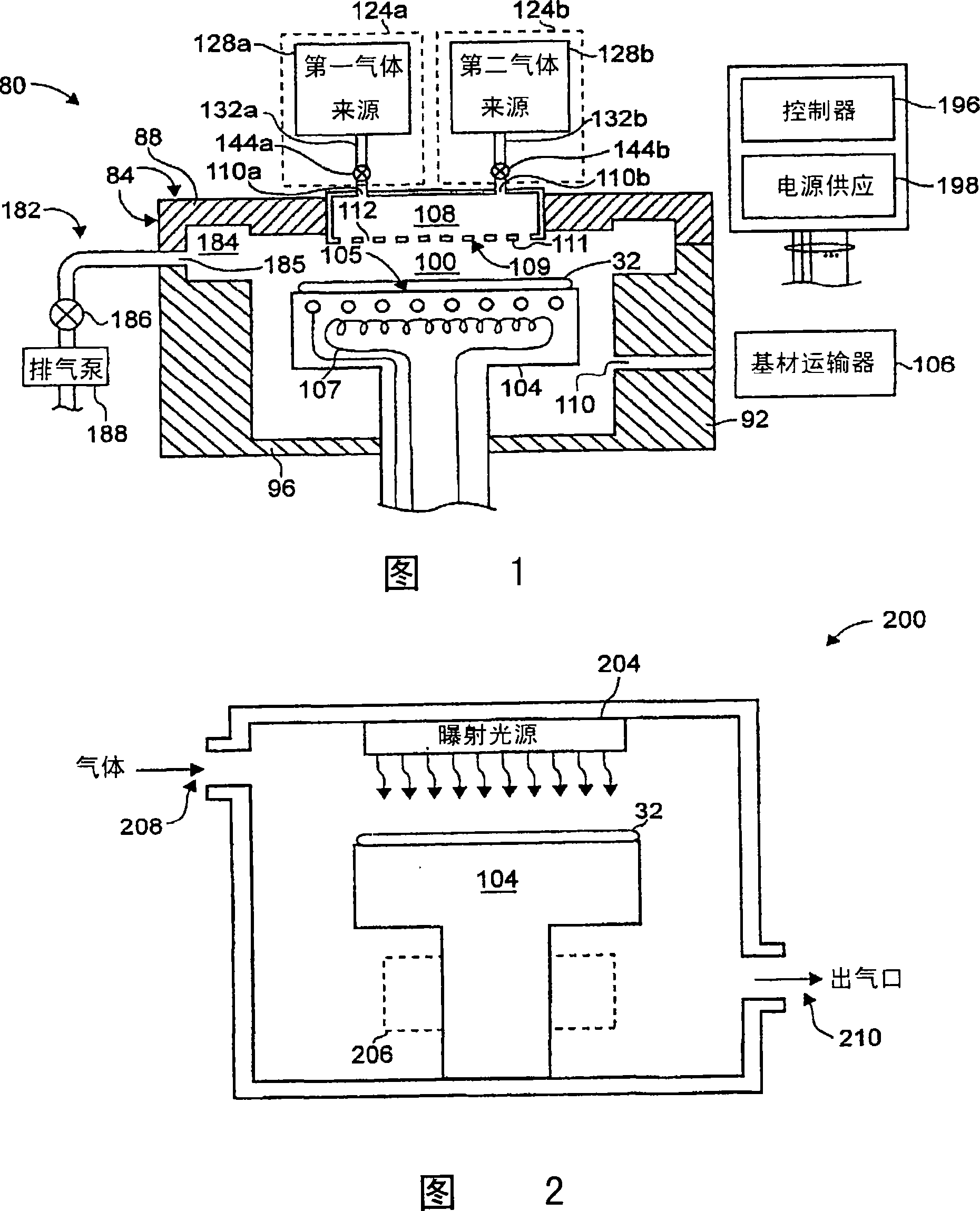

[0060] FIG. 1 schematically illustrates an embodiment of a substrate processing chamber 80 for depositing stressed materials in accordance with the present invention. This demonstration chamber is used to illustrate the invention, but other chambers may be used by those skilled in the art. Accordingly, the scope of the present invention should not be limited to the exemplary embodiment of the chamber or other features mentioned herein. Generally, the chamber 80 is used as a plasma-assisted chemical vapor deposition (PE-CVD) chamber for processing a substrate 32 (eg, a silicon wafer). For example, a suitable process chamber is the Producer manufactured by Applied Materials of Santa Clara, California, USA. SE type room. The chamber 80 includes sealing walls 84 , including a top cover 88 , side walls 92 , and a bottom wall 96 , which seal off a processing zone 100 . The chamber 80 also includes a gasket (not shown) surrounding the processing zone 100 as a gasket for at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com