Antistatic agent composition

A technology of antistatic agent and composition, which is applied in the field of antistatic agent composition, can solve problems such as difficult uniform coating and difficult acquisition, and achieve excellent design performance, excellent color fastness, and excellent durability of antistatic effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

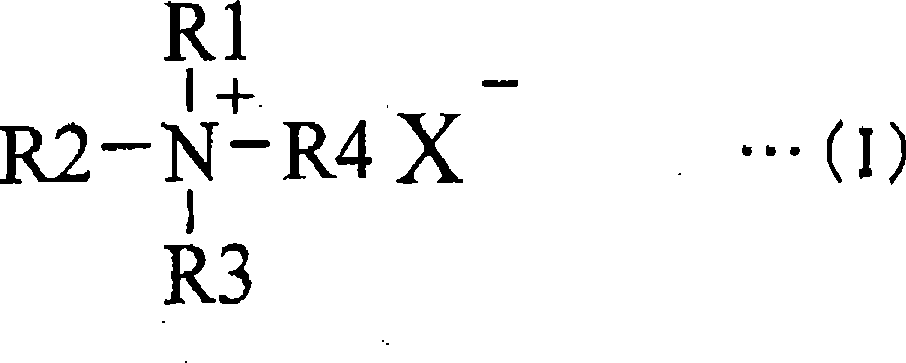

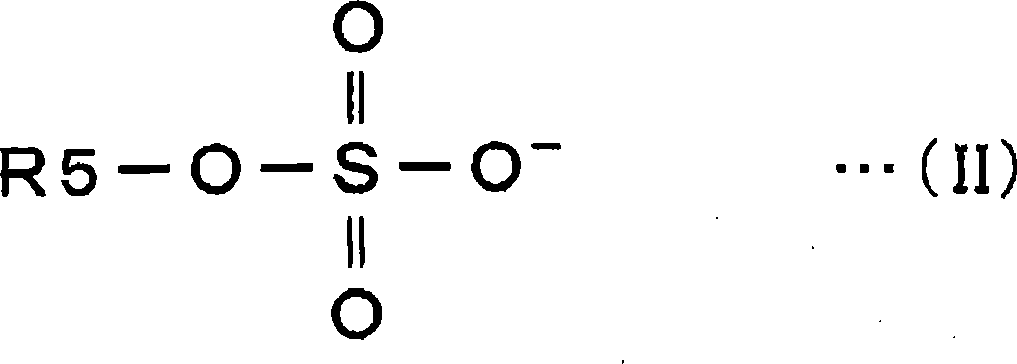

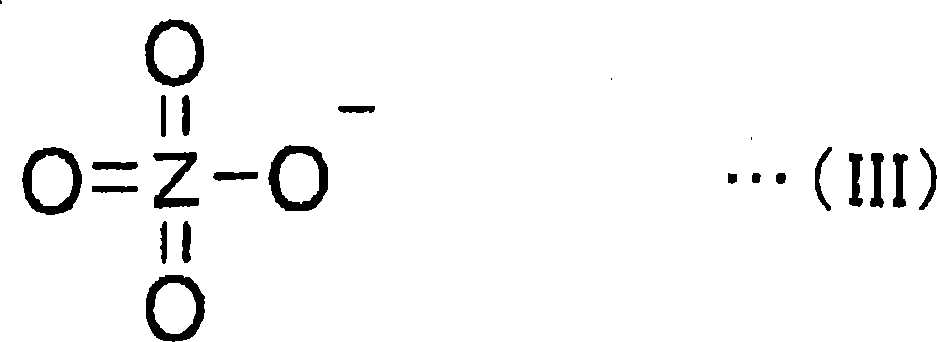

Method used

Image

Examples

Embodiment 1

[0090] 2.0 parts by mass of component A1 (aqueous polyacrylic acid solution manufactured by Aldrich Co.) was diluted with 79.5 parts by mass of ion exchange water, and 10.0 parts by mass of component B1 (aqueous solution of trimethyloctadecylammonium chloride) was added, and then mixed. In addition, 8.5 parts by mass of component C2 (aqueous carbodiimide resin dispersion) was added, and then mixed to obtain an antistatic agent composition.

[0091] Dip the nonwoven fabric into the obtained antistatic agent composition, and use the nonwoven fabric to wipe the surface of the plastic plate (multi-layer light diffusion plate), thereby coating the surface of the plastic plate with the antistatic agent composition, and then drying, Form an antistatic film. In addition, the plastic plate (heat treatment for crosslinking) was heat-treated at 80° C. for 20 minutes to obtain a plastic material (plastic optical element) coated with an antistatic agent composition on the surface.

Embodiment 2 to 5

[0093] In the same manner as in Example 1, except that the composition was replaced with each composition shown in Table 1, an antistatic agent composition was obtained. In the same manner as in Example 1, a plastic material (plastic optical element) coated with the antistatic agent composition on the surface was obtained.

[0094] Table 1

[0095] Example 1

Embodiment 6 to 9 and comparative example 1

[0097] In the same manner as in Example 1, except that the composition was replaced with each composition shown in Table 2, an antistatic agent composition was obtained. In the same manner as in Example 1, a plastic material (plastic optical element) coated with the antistatic agent composition on the surface was obtained.

[0098] Table 2

[0099] Example 6

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com