Method for preparing high Nb-Ti-Lu porous material

A technology of high niobium titanium aluminum and porous materials, applied in the field of intermetallic compounds, to achieve the effects of low density, improved service life and service environment, and high service temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

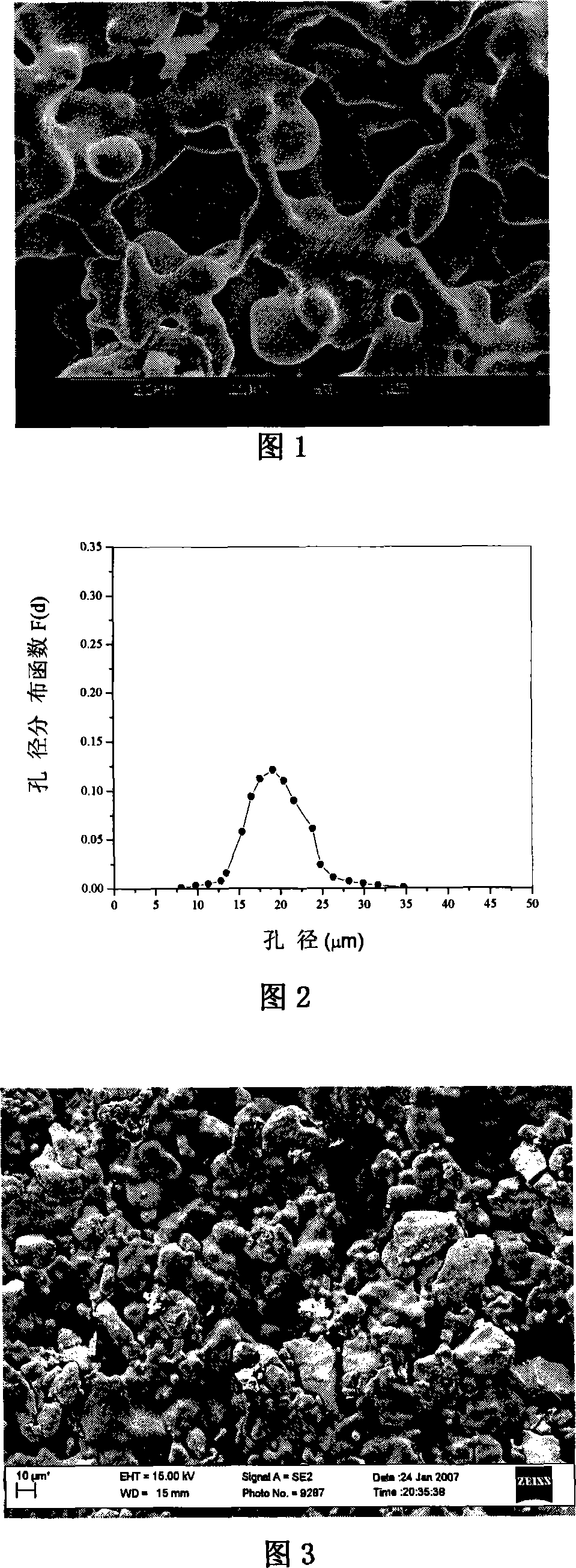

[0017] Example 1: Ti powder and Al powder with a particle size of 40-75 μm, and Nb powder with a particle size of 5-25 μm are used, and the proportions are carried out according to the composition of Ti-48AI-6Nb (at.%). Pressing is carried out at the bottom, and a sheet-like cold compact with a diameter of 33 mm and a thickness of 2 to 3 mm is pressed out. Sintering adopts a two-stage reaction synthesis process, and the vacuum atmosphere is controlled at 1 × 10 -2 ~1×10 -3 pa. The low temperature reaction sintering temperature is 600℃, the holding time is 120min, the high temperature sintering is 1350℃, the holding time is 180min, and the pressing pressure is 1.2KPa. After the reaction was completed, the cooling rate was controlled at 30°C / min. The high-niobium-titanium-aluminum porous material obtained in this way has a pore structure with uniform pore distribution, different sizes and a labyrinth-like pore structure, as shown in Figure 1. The framework of the sintered bo...

Embodiment 2

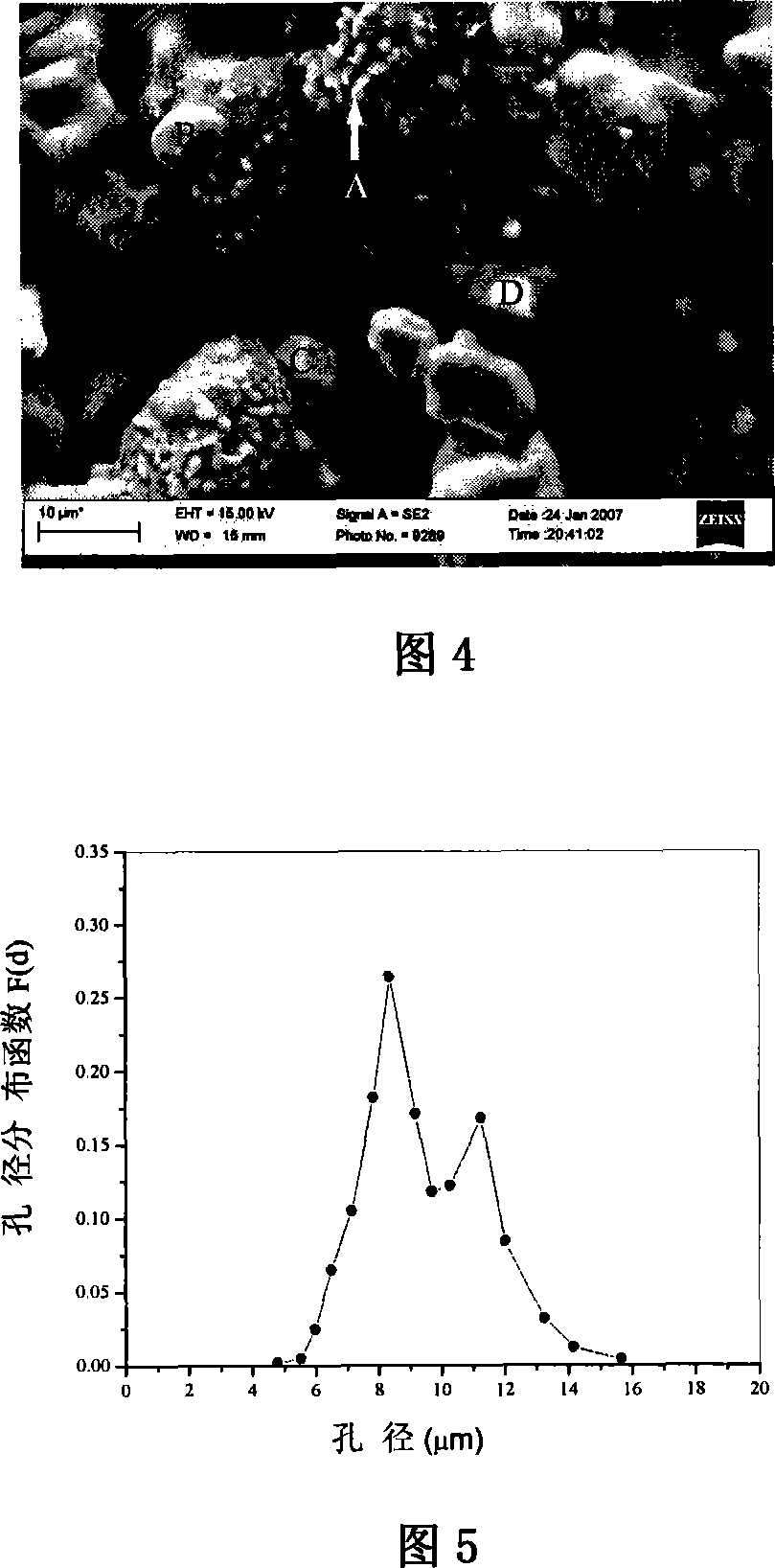

[0018] Example 2: Ti powder and Al powder with a particle size of 75-150 μm and Nb powder with a particle size of 5-25 μm are used, and the proportions are carried out according to the composition of Ti-48Al-8Nb (at.%). Pressing is carried out at the bottom, and a sheet-like cold compact with a diameter of 33 mm and a thickness of 2 to 3 mm is pressed out. Sintering adopts a two-stage reaction synthesis process, and the vacuum atmosphere is controlled at 1 × 10 -2 ~1×10 -3 pa. The low temperature reaction sintering temperature is 550°C, the holding time is 150min, and the high temperature sintering is 1350°C, and the holding time is 180min. The pressing pressure was 2.1KPa. After the reaction was completed, the cooling rate was controlled at 40°C / min. The high niobium titanium aluminum porous material obtained in this way has a pore structure with uniform pore distribution, different sizes and a labyrinth-like pore structure. The sintered body skeleton consists of γ / α 2 ...

Embodiment 3

[0019] Example 3: Ti powder and Al powder with a particle size of 10-25 μm and Nb powder with a particle size of 5-25 μm are used, and the proportions are carried out according to the composition of Ti-48Al-6Nb (at.%). Pressing is carried out at the bottom, and a sheet-like cold compact with a diameter of 33 mm and a thickness of 2 to 3 mm is pressed out. Sintering adopts a two-stage reaction synthesis process, and the vacuum atmosphere is controlled at 1 × 10 -2 ~1×10 -3 Pa. The low temperature reaction sintering temperature is 600 ℃, the holding time is 120 min, and the high temperature sintering is 1335 ℃, and the holding time is 180 min. The pressing pressure was 1.6KPa. After the reaction was completed, the cooling rate was controlled at 30°C / min. The high niobium titanium aluminum porous material obtained in this way has a pore structure with uniform pore distribution, different sizes and a labyrinth-like pore structure. The sintered body skeleton consists of γ / α 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com