Spherical multi-freedom altrasonic electric machine of single vibrator longtitude bend sandwich changer type

An ultrasonic motor and transducer technology, which is applied in the directions of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. , small driving torque, etc., to achieve the effect of three-dimensional proportional coordination of configuration, simple structure and large output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

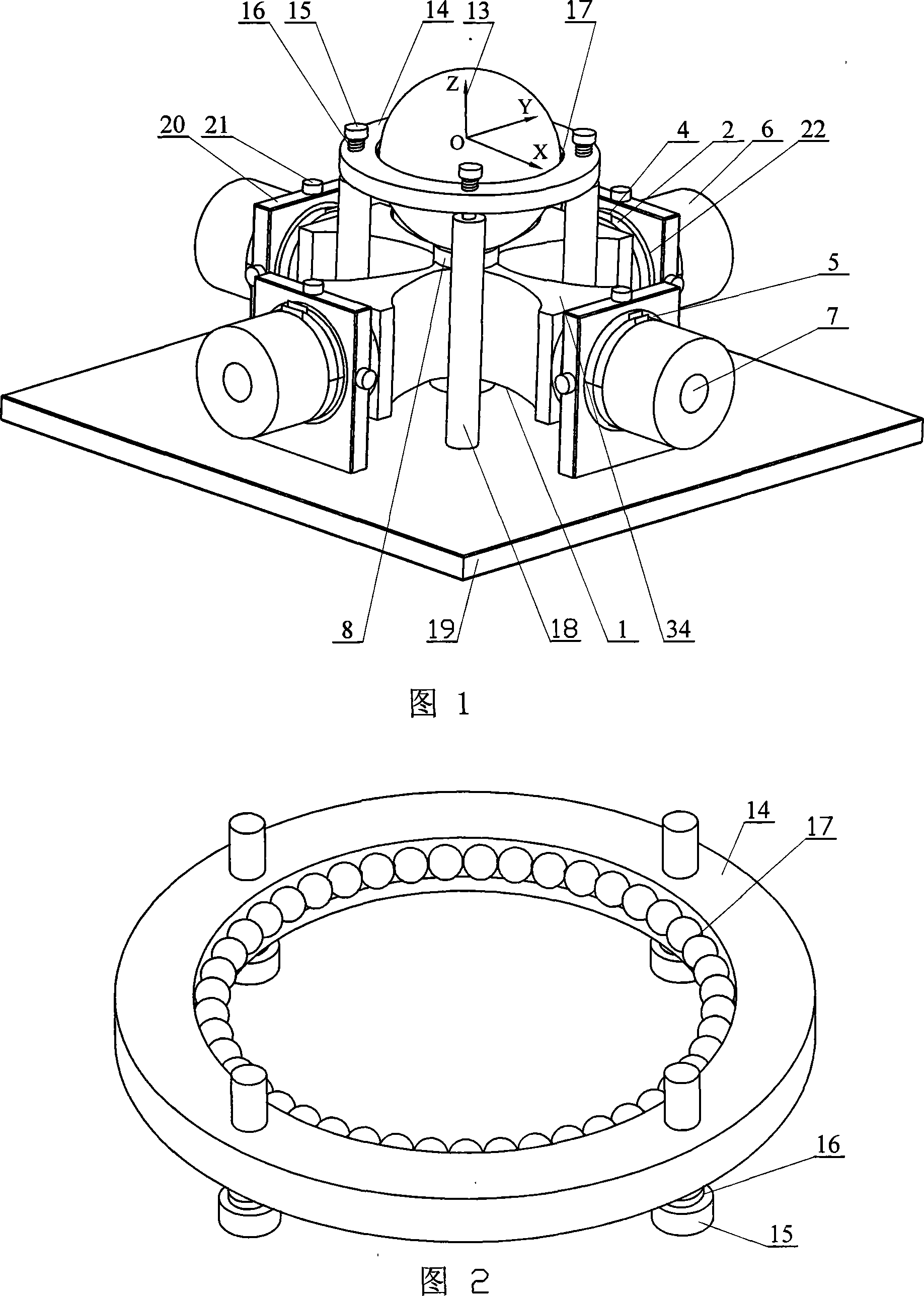

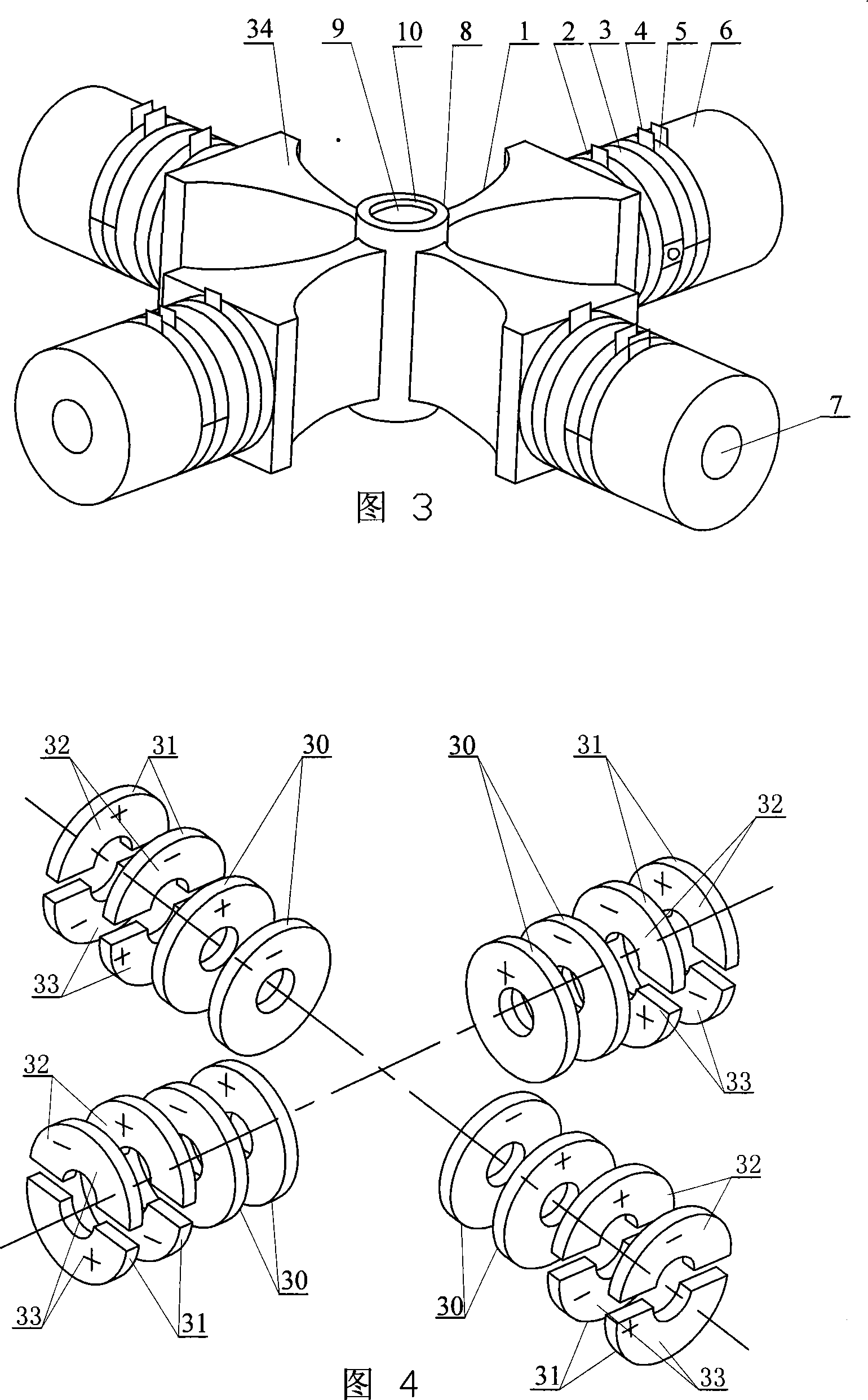

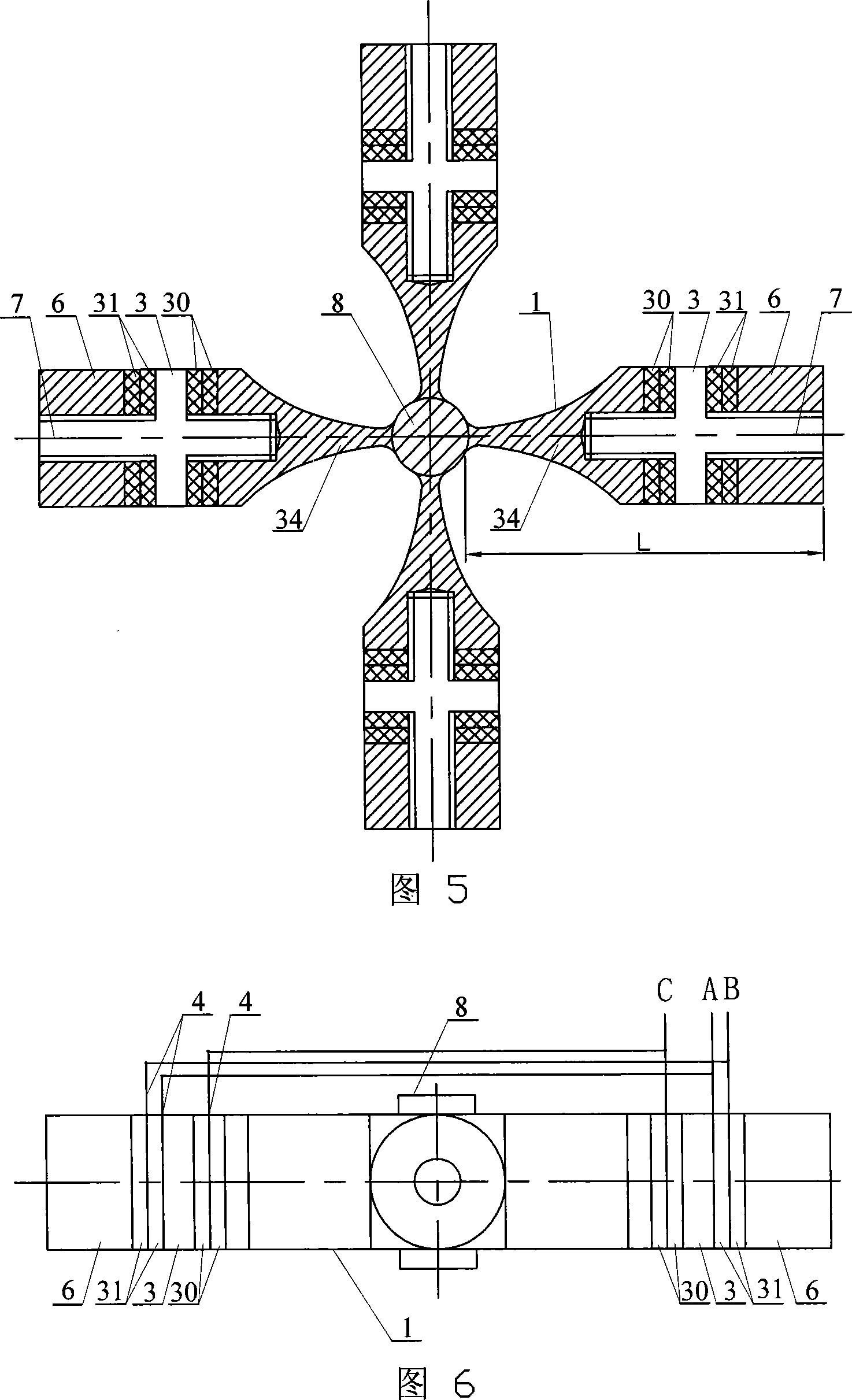

[0008] Embodiment 1: This embodiment is described with reference to FIGS. 1 to 7 . This embodiment is composed of a single-vibrator longitudinal-bending sandwich transducer, a fixed component and a mover ball 13; the single-vibrator longitudinal-bending sandwich transducer consists of a cross Orthogonal horn 1, longitudinal vibration piezoelectric ceramic sheet group 2, flange 3, electrode copper sheet 4, bending vibration piezoelectric ceramic sheet group 5, end cap 6, stud 7 and driving foot 8; A stud 7 is respectively provided on the vertical axis of the orthogonal horn 1, the stud 7 is provided with a flange 3, and the flange 3 is located at the nodal surface position of the longitudinal vibration of the single vibrator longitudinal bending sandwich transducer. The stud 7 between the flange 3 and the large end face of the cross orthogonal horn 1 is equipped with a longitudinal vibration piezoelectric ceramic plate group 2, and the stud 7 between the flange 3 and the end cov...

specific Embodiment approach 2

[0009] Embodiment 2: This embodiment is described with reference to FIGS. 1 to 3 and 5. The fixing assembly of this embodiment consists of a top bead holder 14, a preload 15, a preload spring 16, a sliding ball 17, a preload bracket 18, The base 19 and the driver fixing frame 20 are composed; the ring groove of the top bead frame 14 is equipped with sliding balls 17 , the top bead frame 14 is mounted on the mover ball 13 , and the top bead frame 14 passes through the pre-tightening member 15 and the pre-tightening member. The spring 16 is connected to the upper end of the preloading bracket 18, the lower end of the preloading bracket 18 is fixed on the base 19, the driver fixing frame 20 is fixed on the base 19, the driver fixing frame 20 is fixedly connected with the flange 3, the The single-vibrator longitudinal-bending sandwich transducer is mounted on the base 19 . In this way, the top ball frame 14 is used to assemble the sliding balls 17 to limit the position of the move...

specific Embodiment approach 3

[0010] Embodiment 3: This embodiment is described with reference to FIG. 1 and FIG. 3 . The difference between this embodiment and Embodiment 2 is that an elastic rubber ring 22 is added to the fixing assembly of this embodiment; the elastic rubber ring 22 is provided with between the drive holder 20 and the flange 3 . This arrangement can reduce the influence on the natural mode shape of the single-element longitudinal-bending sandwich transducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com