Biological fluidized bed reactor for raising mixed gas and liquid

A biological fluidized bed and gas-liquid mixing technology, applied in the direction of sustainable biological treatment, aerobic process treatment, etc., can solve the problems of low load, increased project operation cost, complex process and operation, etc., and achieve the effect of preventing short flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

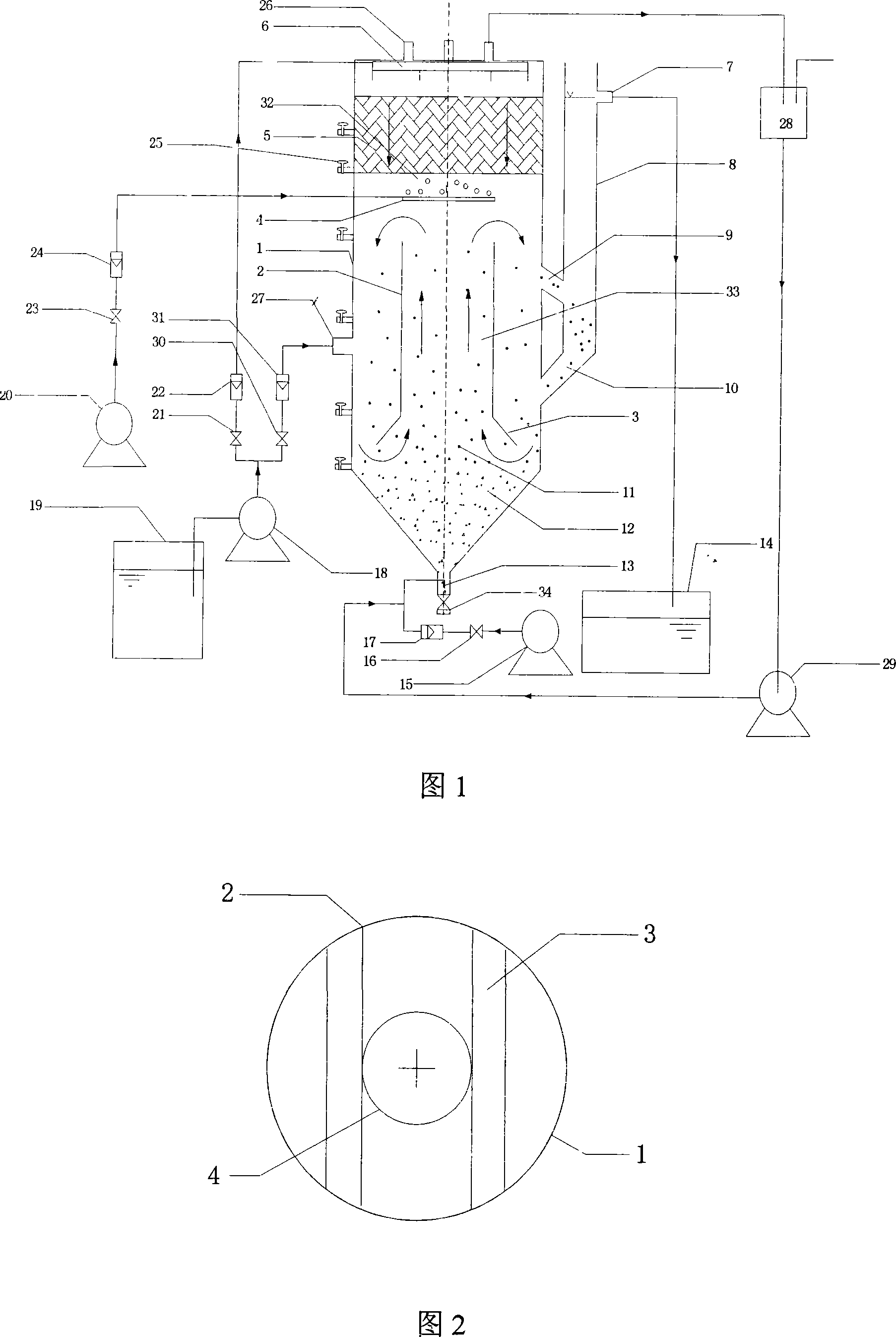

[0020] As shown in Figure 1, the gas-liquid mixed lifting biological fluidized bed reactor has a reactor main body 1, and the reactor main body 1 is provided with a top water distributor 6, an aerobic reaction zone 32, and an anoxic reaction zone 33 sequentially from top to bottom , sludge settling area 12, trapezoidal reflux port 13, wherein aerobic reaction area 32 includes biological filler layer 5, microporous aeration ring 4, anoxic reaction area 33 includes reaction chamber partition 2, backflow baffle 3, biological carrier 11. The partition 2 of the reaction chamber is two parallel longitudinal partitions. Both sides of the partition are connected to the wall of the main body of the reactor, and the lower end of the partition is connected to the backflow baffle 3. There is a middle wall on the side wall of the main body of the reactor 1. Water inlet 27, sampling port 25, sedimentation area inlet pipe 9, sedimentation area return pipe 10, sedimentation area inlet pipe 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com