A composite ceramic brick

A technology of ceramic tiles and aluminum pigments, applied in thin material processing, transportation and packaging, etc., can solve the problems of poor effect, can only be painted on the glaze, and the decoration can not be fully reflected, and achieve the advantages of weather resistance, easy to Aging or deformation, high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In the preparation method of the above-mentioned composite ceramic tile, it also includes applying a primer that does not contain aluminum pigment and mica titanium pearlescent pigment on the surface of the ceramic tile before applying the above-mentioned coating; the ceramic tile is preferably an unglazed tile; the aluminum pigment It is one or more of the non-floating aluminum powder; the mica titanium pearlescent pigment is mica titanium pearlescent powder, the pigment of non-metal oxide coated mica titanium pearlescent powder, the pigment of transparent organic pigment coated mica titanium pearlescent powder one or more of.

[0028] Selection of ceramic tiles. The ceramic brick of the present invention refers to the ceramic brick defined by the national standard GB / T9195-1999. The ceramic brick is made of natural minerals such as clay, feldspar, and quartz as raw materials, which are crushed, mixed, ground, shaped, dried, and sintered ( into) and other processes ma...

Embodiment 1

[0068] One, preparation coating: raw material name weight part

[0069] 101 aluminum powder paste 7

[0070] 343-3 resin 69.9

[0071] Xylene 23

[0072] Defoamer 0.1

[0073] Second, select the base material: ceramic tile a

[0074] 3. Application method: brush one coat

[0075] 4. Drying conditions and forms: normal temperature, 7 days, solvent volatilization, oxidation polymerization.

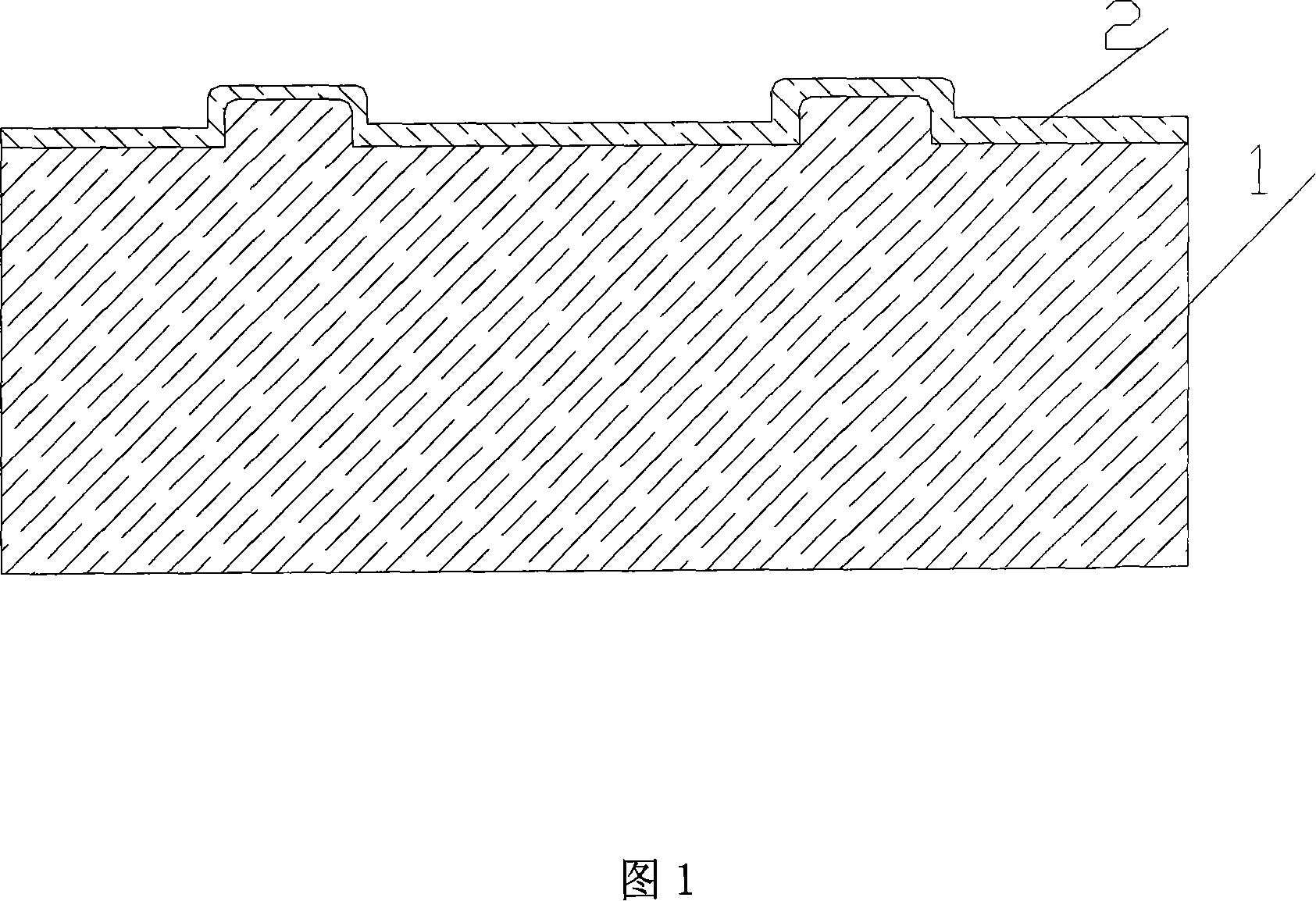

[0076] A composite ceramic tile coated with a flat and smooth appearance and a silver-white metallic color coating layer 2 (as shown in FIG. 1 ) can be obtained on the ceramic tile 1 , and the adhesion of the coating film is grade 1 as measured by the cross-hatch method.

Embodiment 2

[0078] One, preparation coating: raw material name weight part

[0079] 4191 resin 68.9

[0080] PCR214 aluminum powder 8

[0081] n-Butanol 5

[0082] Xylene 5

[0083] Toluene 13

[0084] Decontamination agent 0.1

[0085] Second, select the base material: ceramic tile a

[0086] 3. Application method: one air spray

[0087] 4. Drying conditions and form: 60°C±2°C, 20 minutes, the solvent evaporates.

[0088] A composite ceramic tile coated with a flat and smooth appearance and a silver-white metallic color coating layer 2 (as shown in FIG. 1 ) can be obtained on the ceramic tile 1 , and the adhesion of the coating film is grade 1 as measured by the cross-hatch method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com