Sticking removing painting compsns. having addhesive for affecting viscosity removal

A technology of composition and additives, applied in the direction of coatings, devices for coating liquids on surfaces, special surfaces, etc., can solve problems such as not very feasible, slow, and increased adhesion to substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

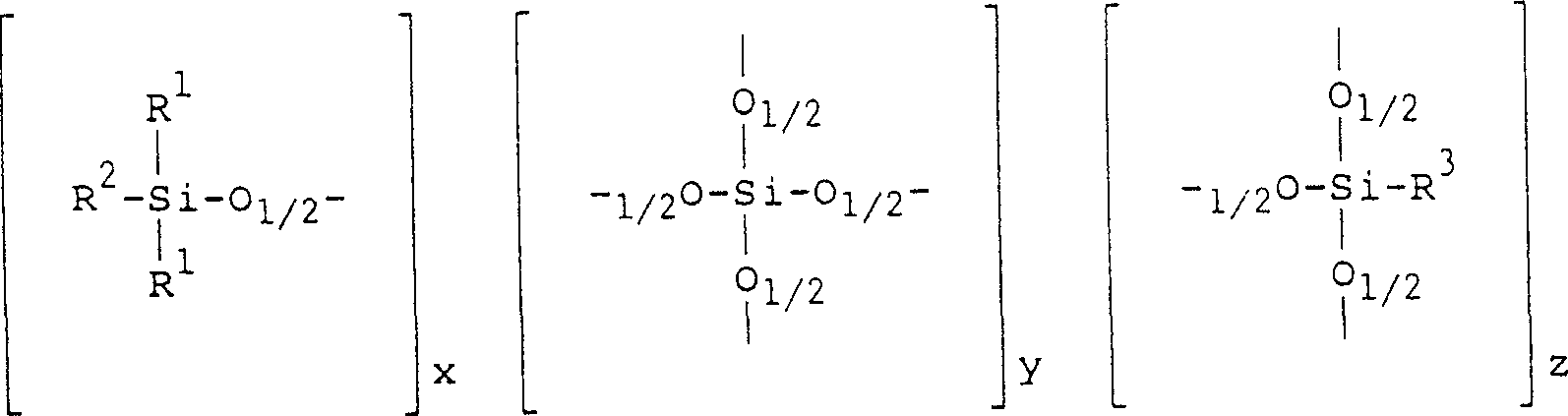

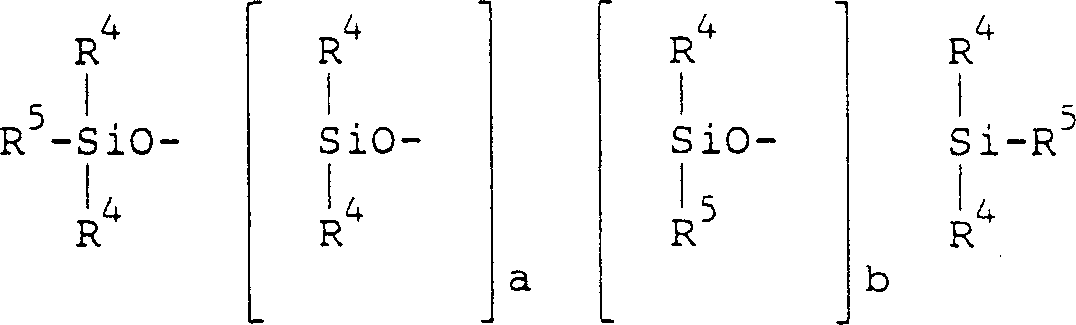

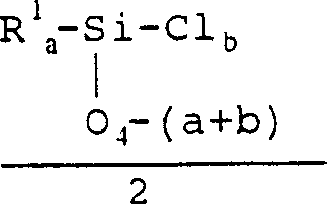

Method used

Image

Examples

Embodiment 1

[0175] A 50% toluene solution (165 g) of a commercially available MQ resin with an average molecular weight of 2442 g / mol, an M / Q ratio of 0.67 and a SiOH content of 1.5% (165 g) and 14.9 g (0.018 mole) of acryloyloxypropyl ( acryloxypropyl) multifunctional polydimethylsiloxane is mixed under stirring in a 500ml three-necked flask, and a stirrer, a thermometer and a reflux condenser are equipped in the flask, and the polydimethylsiloxane is passed through Synthesized as described in Example 1 of German Patent 3810140 and has the following average structural formula

[0176] CH 2 =CHCOOCH 2 CH 2 CH 2 Me 2 SiO(SiMe 2 O) 6.2 SiMe 2 CH 2 CH 2 CH 2 OOCCH=CH 2

[0177] Afterwards, air was removed from the reaction flask by bubbling nitrogen. Under a nitrogen blanket and with stirring, 0.54 g (0.3% by weight) of trifluoromethanesulfonic acid was added. Next, the temperature was raised to 90° C. within 30 minutes, and stirring was continued at this temperature for a furt...

Embodiment 2

[0181] 95.2 g of a 60% toluene solution of a commercially available MQ resin with an average molecular weight of 1133 g / mol, an M / Q ratio of 0.75 and a SiOH content of 1.4%, 27.1 g (0.075 moles) of 1,3-bis-(3-acryloyloxy propyl)-tetramethyldisiloxane (synthesized by esterification of 1,3-bis(3-hydroxypropyl)-tetramethyldisiloxane (ABCR) with acryloyl chloride in benzene / pyridine ) and 0.25 g (0.3% by weight) of trifluoromethanesulfonic acid were heated to 95° C. and stirred at this temperature for 6 hours. Thereafter, the reaction solution was cooled to 50° C., neutralized with 2% by weight of sodium carbonate as described in Example 1, and then filtered. The filtrate was concentrated in a rotary evaporator, then vacuum distilled (80°C, 2 torr). The reaction product, hereinafter referred to as CRA-2, was a homogeneous yellow substance with a viscosity of 24, 300 mPas (20° C.), which was dissolved in toluene to form a clear solution.

[0182] Gel permeation chromatography (GP...

example 3

[0184] Polydimethylsiloxane (23.7 g, 0.01 mole) having a part of the side end acryloxypropyl functionalized polydimethylsiloxane (23.7 g, 0.01 moles)

[0185] Me 3 SiO(SiMe 2 O) 16.2 (CH 2 =CHCOOCH 2 CH 2 CH 2 SiMeO) 7.8 SiMe 3 With 245 g of a commercially available MQ tree (average molecular weight: 2067 g / mol, M / Q ratio: 0.71; and SiOH content: 0.25%) in 50% xylene solution and 0.78 g (0.3% by weight) of trifluoromethanesulfonic acid Stir at 100°C for 6 hours under nitrogen atmosphere. When the reaction mixture was cooling, 2% by weight of sodium carbonate was added and the mixture was stirred until no traces of acid could be detected. After filtration, volatile components were removed by distillation at 80°C and 2 torr. A homogeneous resinous product (146 g) was obtained which 1 H. 13 C and 29 SiNMR spectroscopic analysis has dimethylsiloxy and (acryloxypropyl)methylsiloxy units, as well as M and Q units.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com