A kind of fiber reinforced ti/al layered composite material and preparation method thereof

A layered composite material and fiber-reinforced technology, applied in the field of Ti/Al layered composite material and its preparation, can solve the problems of low mechanical properties and complex preparation process, and achieve the effects of optimized performance, simple process and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

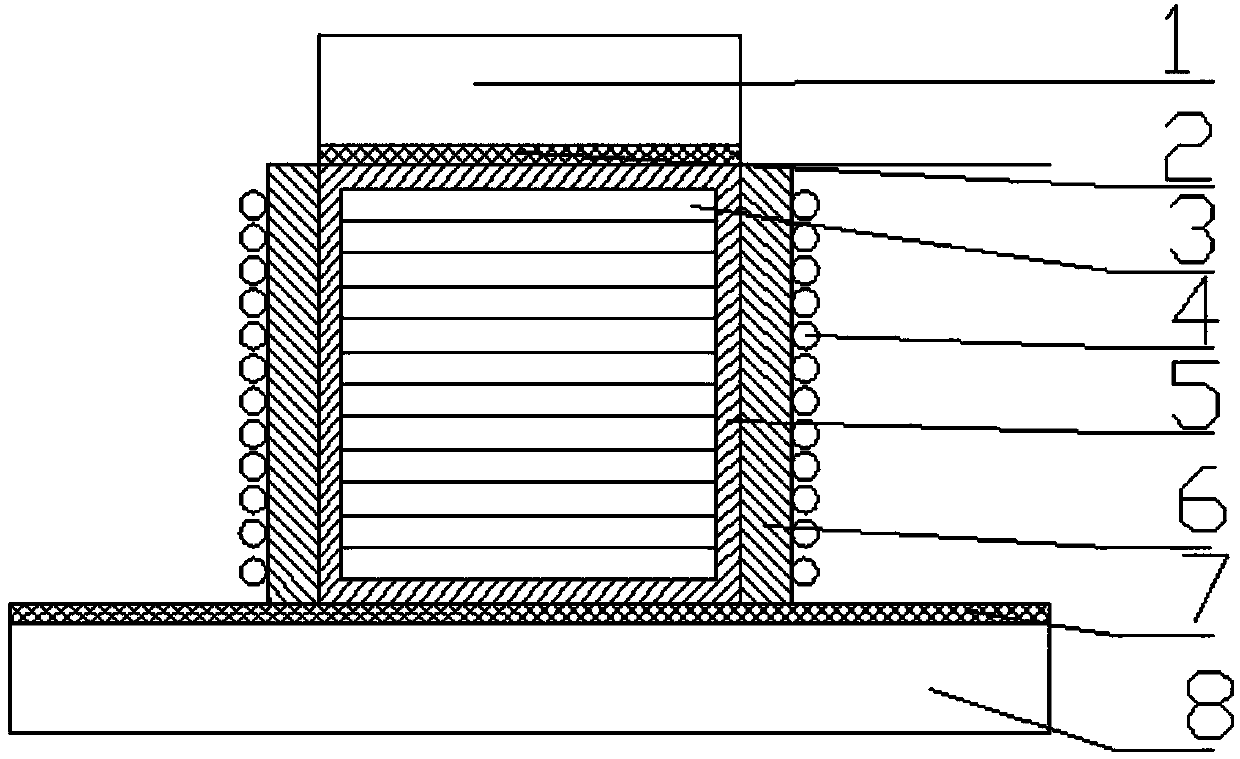

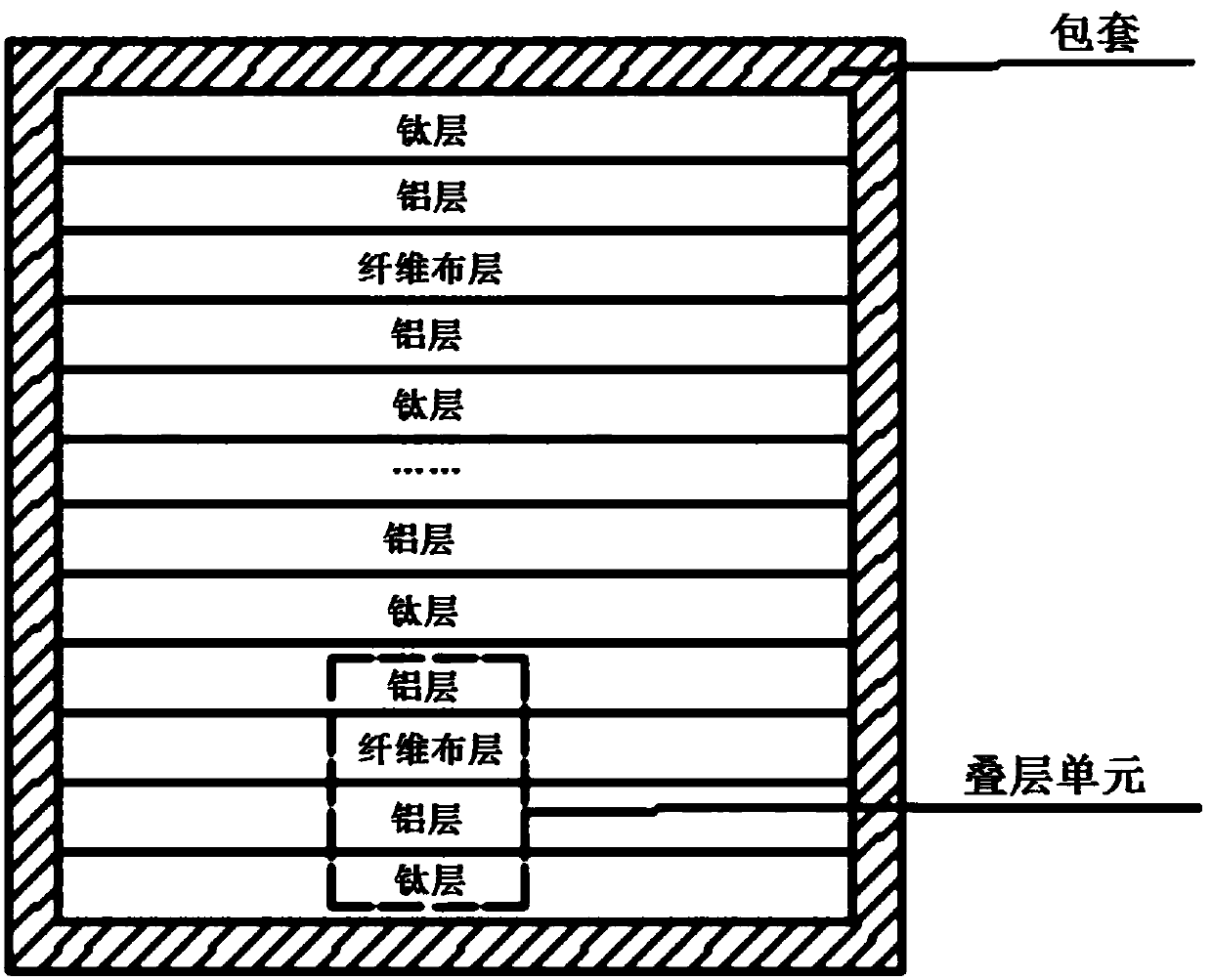

[0033] Embodiment 1: This embodiment is a fiber-reinforced Ti / Al layered composite material, which is composed of a layered core material and a sheath, and the sheath uses a titanium plate with a thickness of 0.5 mm to 1 mm or a thickness of 0.5 mm. Made of 0.5mm-1mm stainless steel plate; the layered core material is a titanium layer and several layers of repeated laminated units from top to bottom, and the laminated units are aluminum layers, Fiber cloth layer, aluminum layer and titanium layer.

[0034] In this embodiment, aluminum has better deformability and fluidity near the melting point temperature, and is impregnated into the carbon fiber under the action of pressure, and is combined with aluminum to form a carbon fiber-reinforced aluminum matrix composite material; at the same time, under the action of pressure, the titanium foil A solid-phase diffusion reaction occurs with the aluminum foil and is connected as a whole.

specific Embodiment approach 2

[0035]Embodiment 2: The difference between this embodiment and Embodiment 1 is that the fiber cloth layer is T700 series 3K bidirectional twill carbon fiber cloth, T700 series 3K bidirectional plain carbon fiber cloth, T700 series 6K unidirectional carbon fiber cloth, M40J Series 6K carbon fiber unidirectional woven fabric, copper-plated T700 series 3K carbon fiber plain two-way fabric, surface nickel-plated T700 series 3K carbon fiber plain two-way fabric, surface nickel-plated T700 series 6K carbon fiber unidirectional fabric, high-strength silicon carbide fiber unidirectional cloth or high-strength silicon carbide fiber two-way cloth. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0036] Specific implementation mode three: the difference between this implementation mode and specific implementation mode two is:

[0037] When the T700 series 3K bidirectional twill carbon fiber cloth is used as the fiber cloth layer, the fibers in the fiber cloth layers of the adjacent laminated units are arranged in a 45° cross direction;

[0038] When the T700 series 6K unidirectional carbon fiber cloth is used as the fiber cloth layer, the fiber axes in the fiber cloth layers of adjacent laminated units are arranged vertically or crossed at 45°;

[0039] When the M40J series 6K carbon fiber unidirectional woven fabric is used as the fiber cloth layer, the fibers in the fiber cloth layers of the adjacent laminated units are arranged in a cross direction at 45°;

[0040] When the nickel-plated T700 series 6K carbon fiber unidirectional cloth is used as the fiber cloth layer, the fibers in the fiber cloth layers of adjacent laminated units are arranged vertically;

[0041...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com