Method for manufacturing linear bearing made from full stainless steel

A technology of linear bearings and manufacturing methods, applied in the direction of linear motion bearings, bearings, shafts and bearings, etc., can solve problems such as shortened service life, difficulty in ensuring stability of quality, and surface wear of raceways

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Manufacturing method of stainless steel ferrule

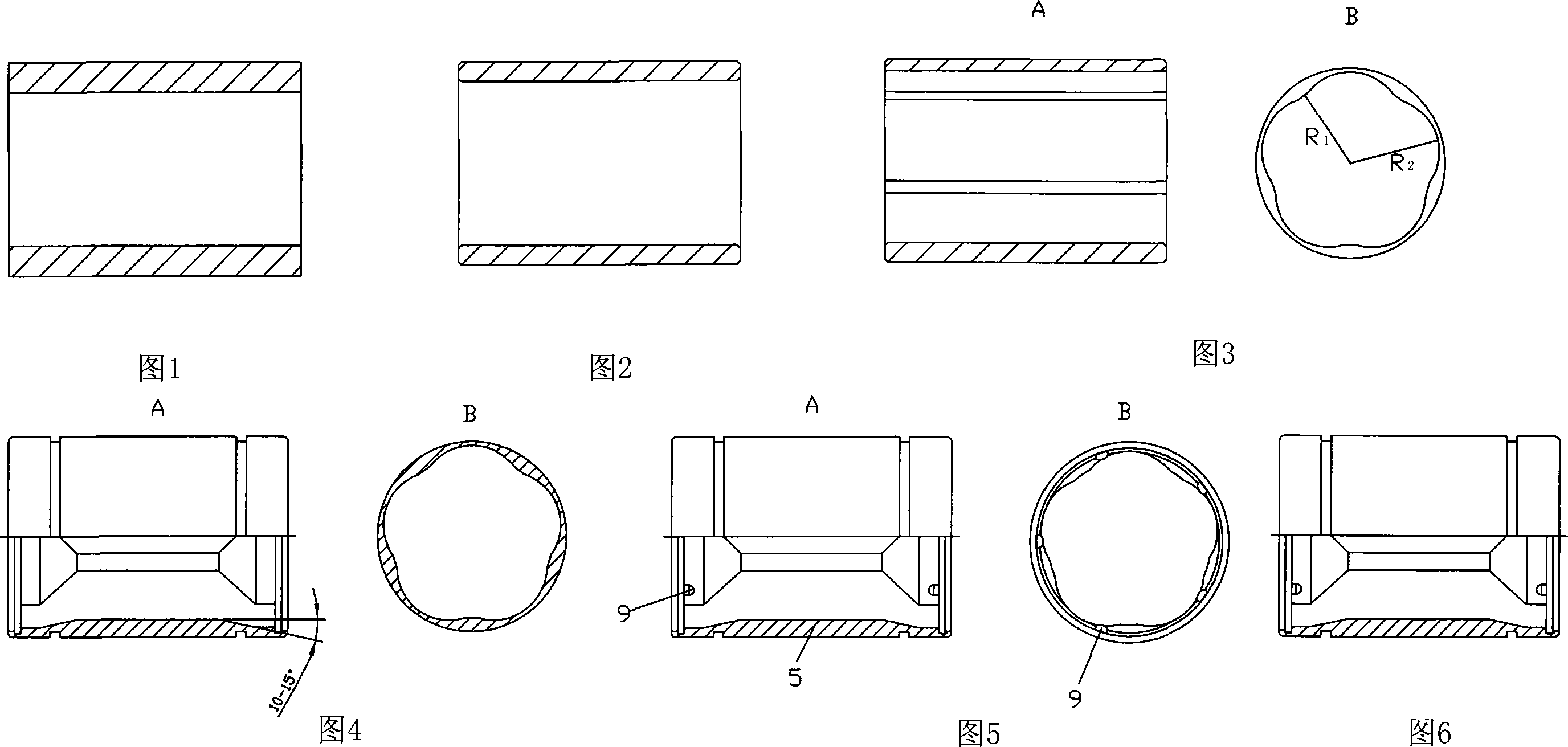

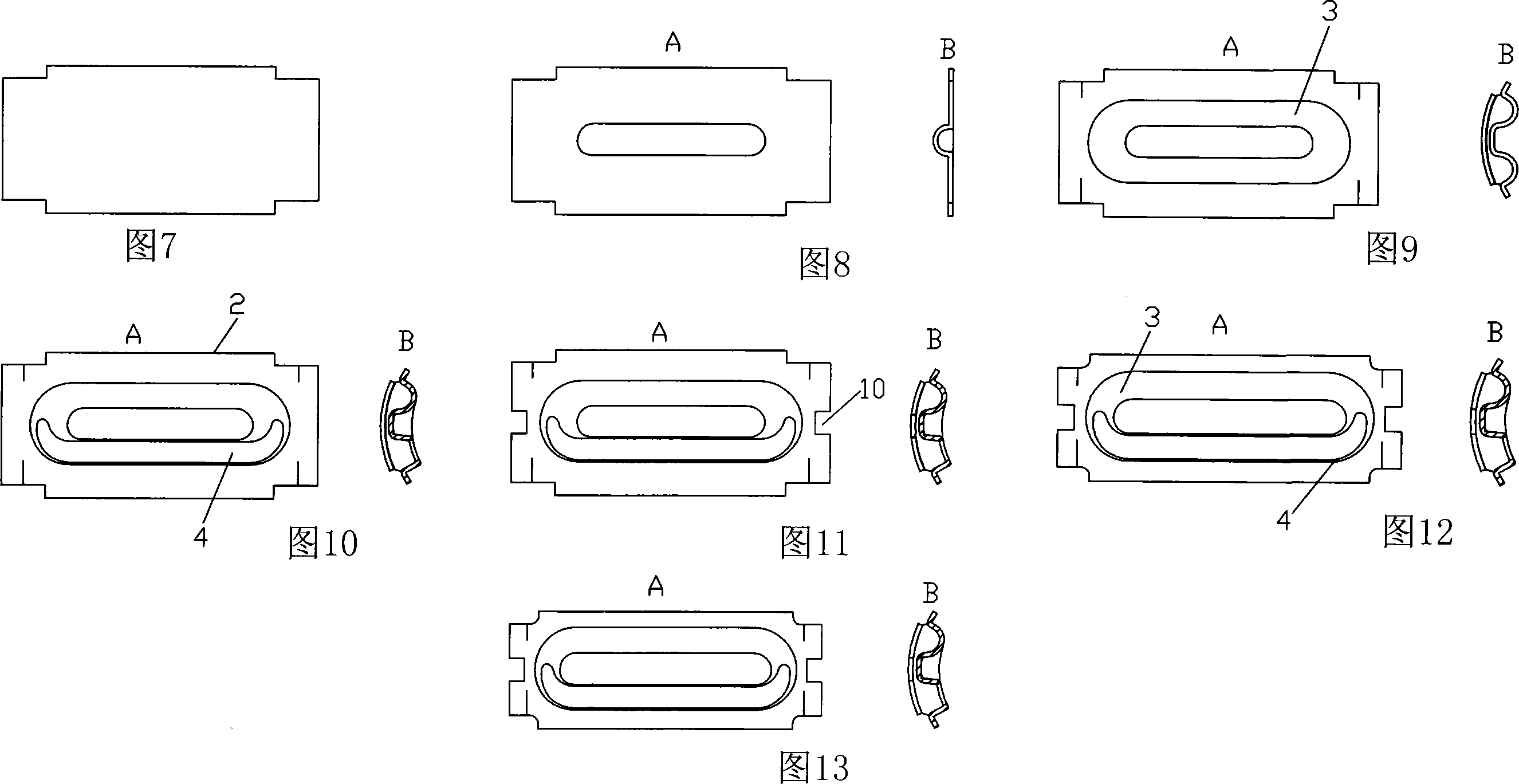

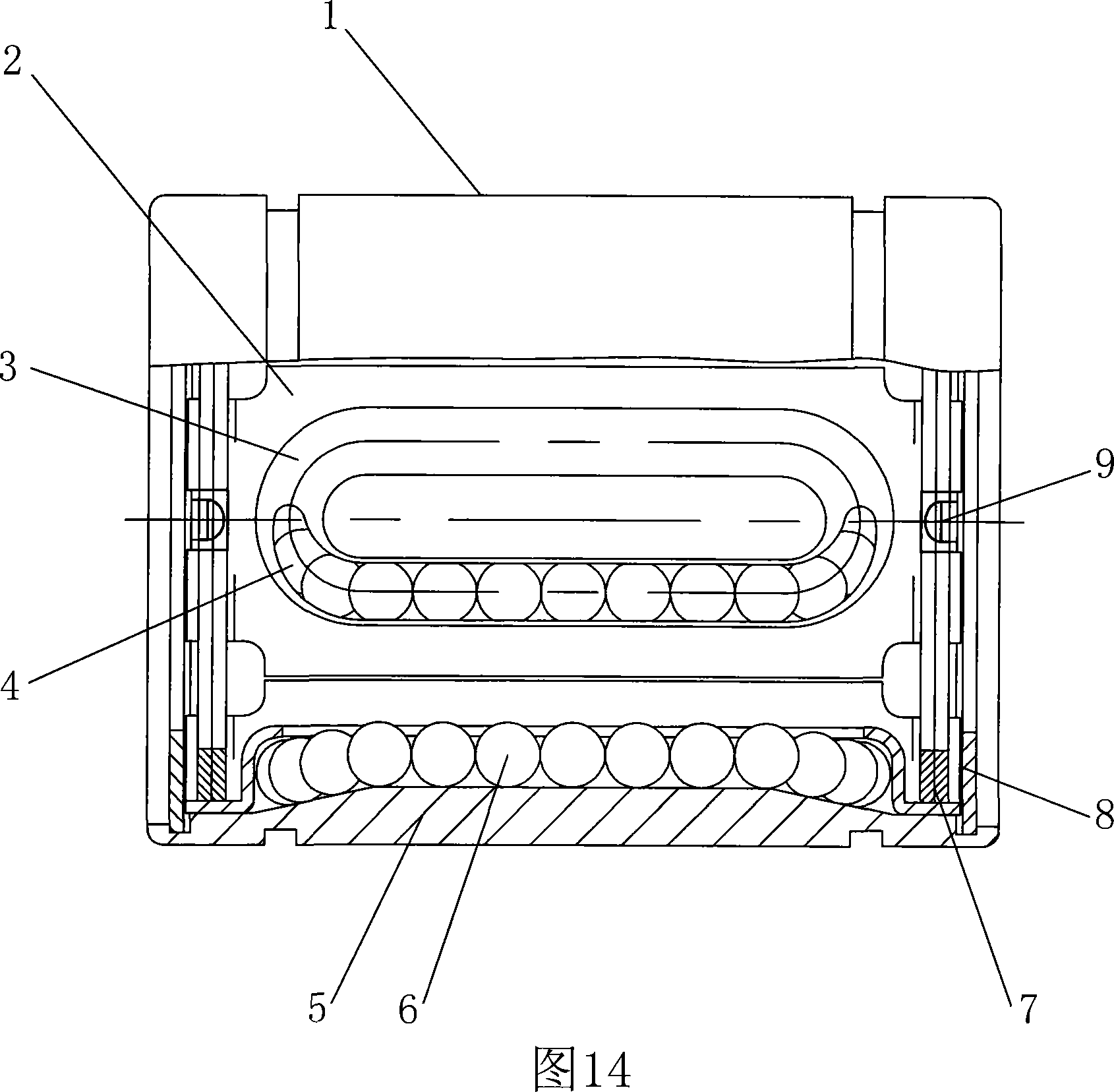

[0017] The processing flow of the stainless steel bearing ring is shown in Figures 1 to 6. The stainless steel bearing ring is made of 9Gr18, which is a high-carbon and high-chromium martensitic stainless steel. Its performance is mainly due to its high mechanical strength, and its hardness can reach above HRC60°C through high-temperature heat treatment. At the same time, the stainless steel has the same acid resistance, alkali resistance and high humidity resistance as other stainless steels. It can work in high temperature and water environment, no rust, no corrosion, and the price is 40% cheaper than other stainless steel. However, it is very difficult to cut and process stainless steel. At present, only stainless steel rods or pipes are available in the market. The stainless steel pipe is taken as an example to illustrate the manufacturing method of stainless steel bearing rings. Cut the inner and outer diameter all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com