Gas supply-discharge system for base plate sintering furnace

A technology of exhaust system and sintering furnace, which is applied to furnaces, furnace types, electrical components, etc., can solve problems such as increased operating costs, blockage of heat exchangers, low energy conversion efficiency, etc., to improve energy conversion efficiency and improve decomposition efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

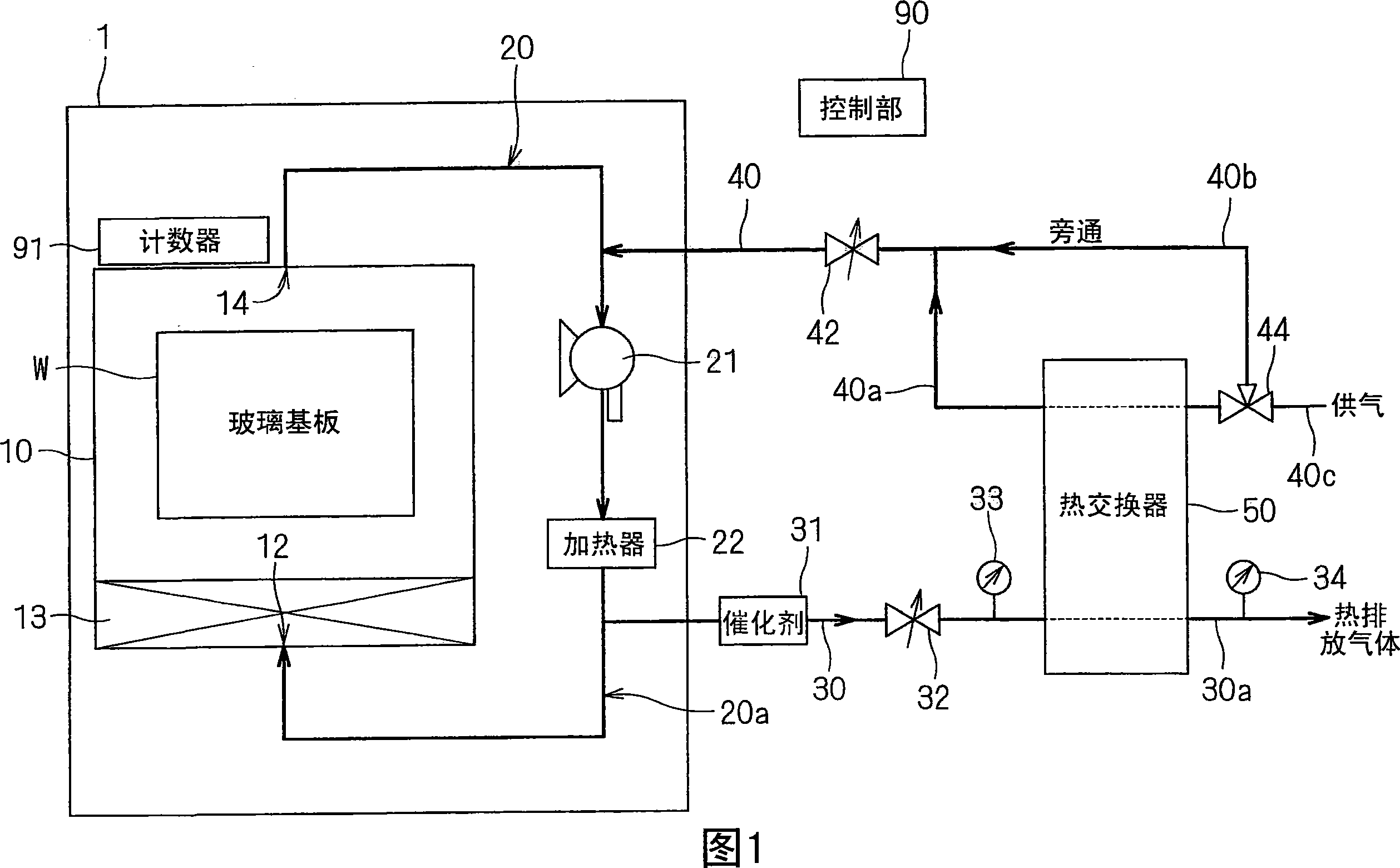

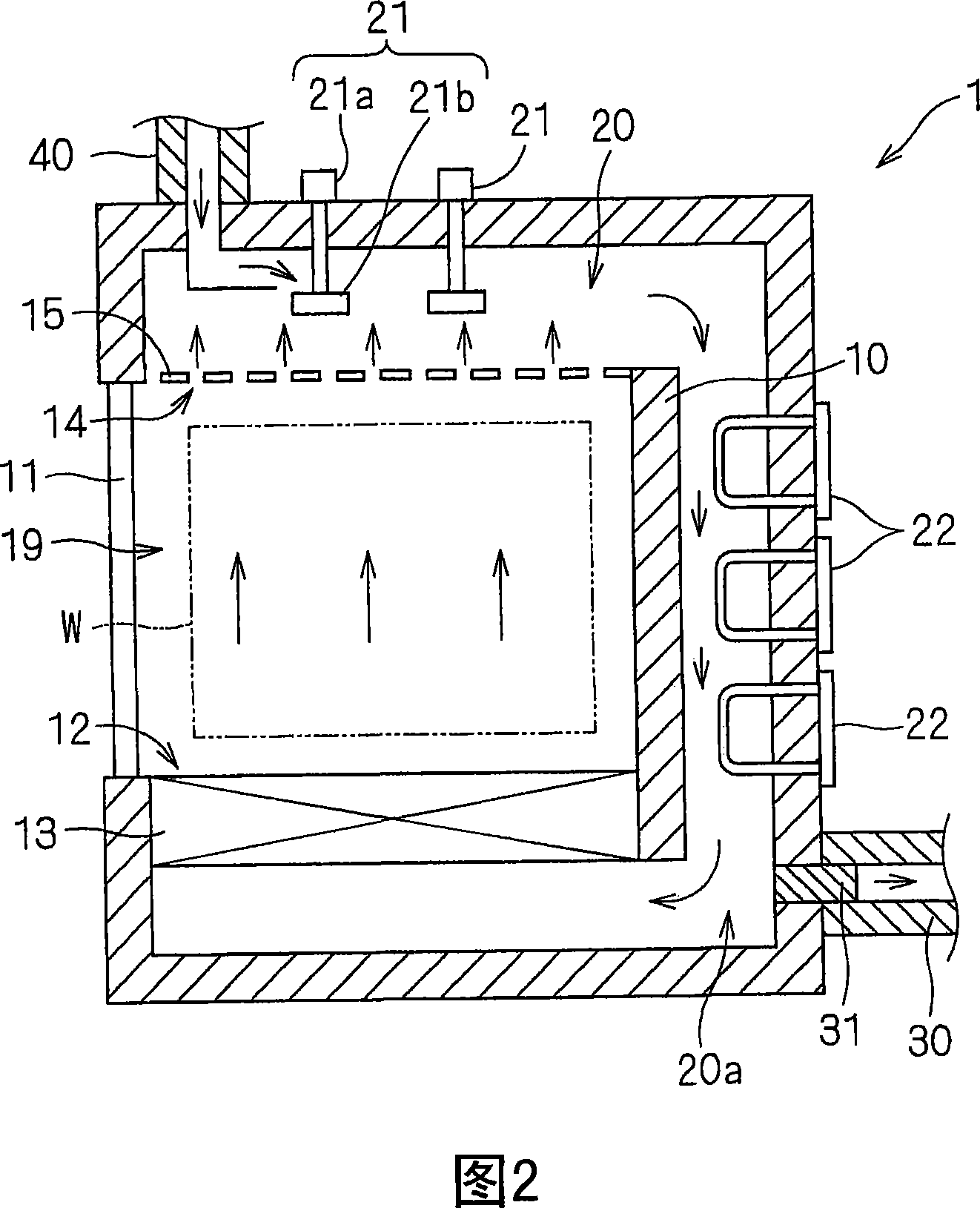

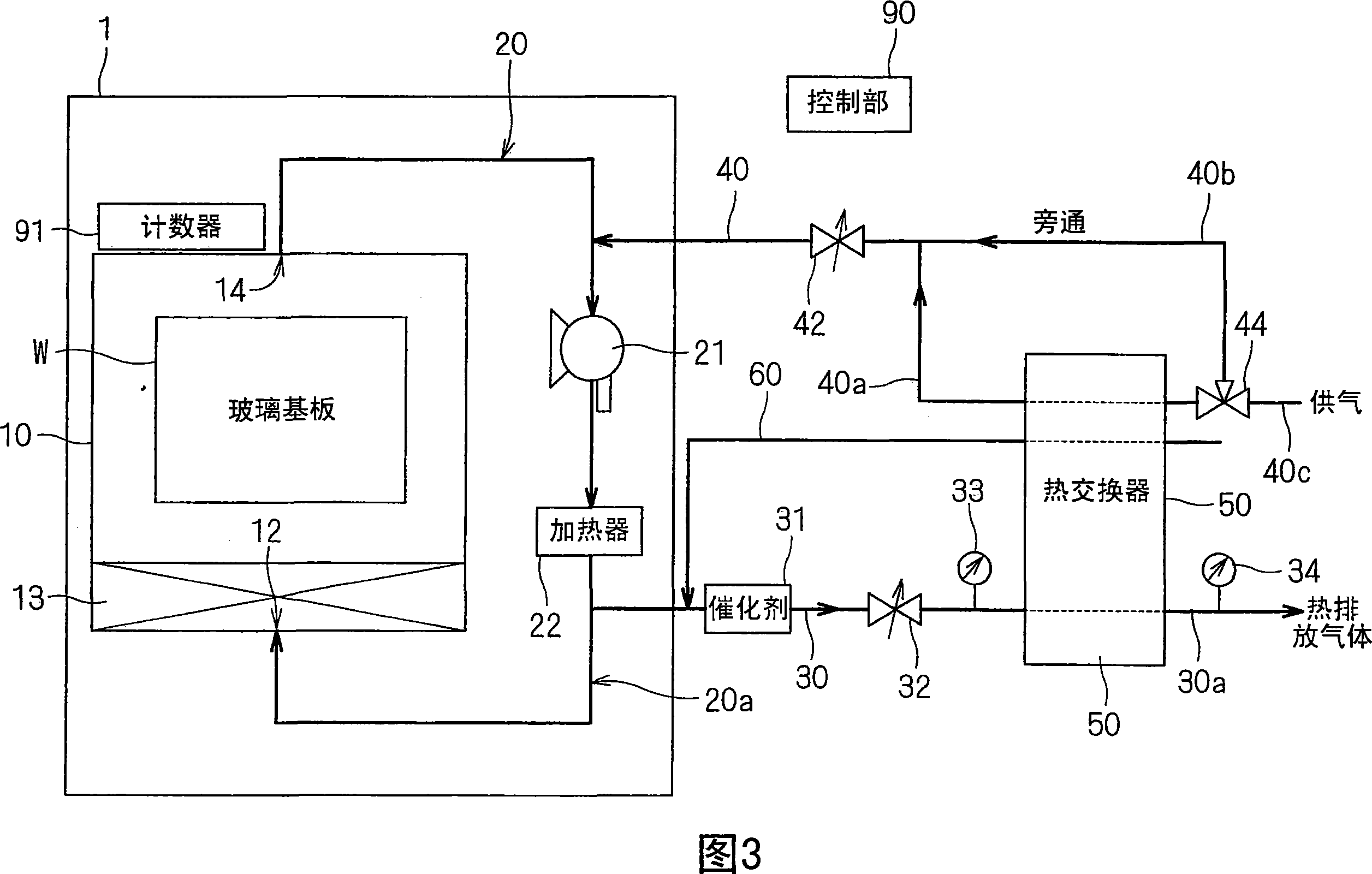

[0047] FIG. 1 is a schematic diagram showing the configuration of main parts of an air supply and exhaust system of a substrate sintering furnace according to the present invention. In addition, FIG. 2 is a cross-sectional view of the substrate sintering furnace seen from above. The substrate sintering furnace 1 is a hot air furnace for sintering a square glass substrate W (substrate in the present invention) coated with colored ink or the like. The substrate sintering furnace 1 has: a furnace body 10 for accommodating a glass substrate W and performing a sintering process; a circulation path 20 for circulating hot air discharged from the furnace body 10 and supplying it again to the furnace body 10; a fan 21 provided in The circulation path 20 is used to circulate the hot air; and the heater 22 is arranged on the circulation path 20 for heating the hot air. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com