Method for preparing Pt/C catalysts for fuel batter with proton exchanging film

A technology of proton exchange membrane and fuel cell, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, catalyst carrier, etc. It can solve the problems of shortening reaction time and long reaction time, and achieve the effect of shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] According to the preparation method of the Pt / C catalyst provided by the present invention, the preparation process of the suspension includes mixing carbon black, a protective agent, a platinum compound and a solvent.

[0027] Preferably, the preparation process of the suspension comprises the following steps:

[0028] (1) Mix the protective agent with the solvent;

[0029] (2) Disperse the carbon carrier in the mixture of protective agent and solvent;

[0030] (3) adding the platinum compound into the solvent obtained in step (2) in which the carbon carrier is dispersed, so that the carbon carrier absorbs the platinum compound.

[0031] Wherein, the solvent may be water, alcohol solvent or a mixture thereof. Alcohol solvent can be existing various alcohol solvents, is preferably the monohydric alcohol of 2-6 carbon number, dibasic alcohol or polyhydric alcohol, more preferably ethanol, propanol, isopropanol, n-butanol, isobutanol One or more of alcohol, ethylene gl...

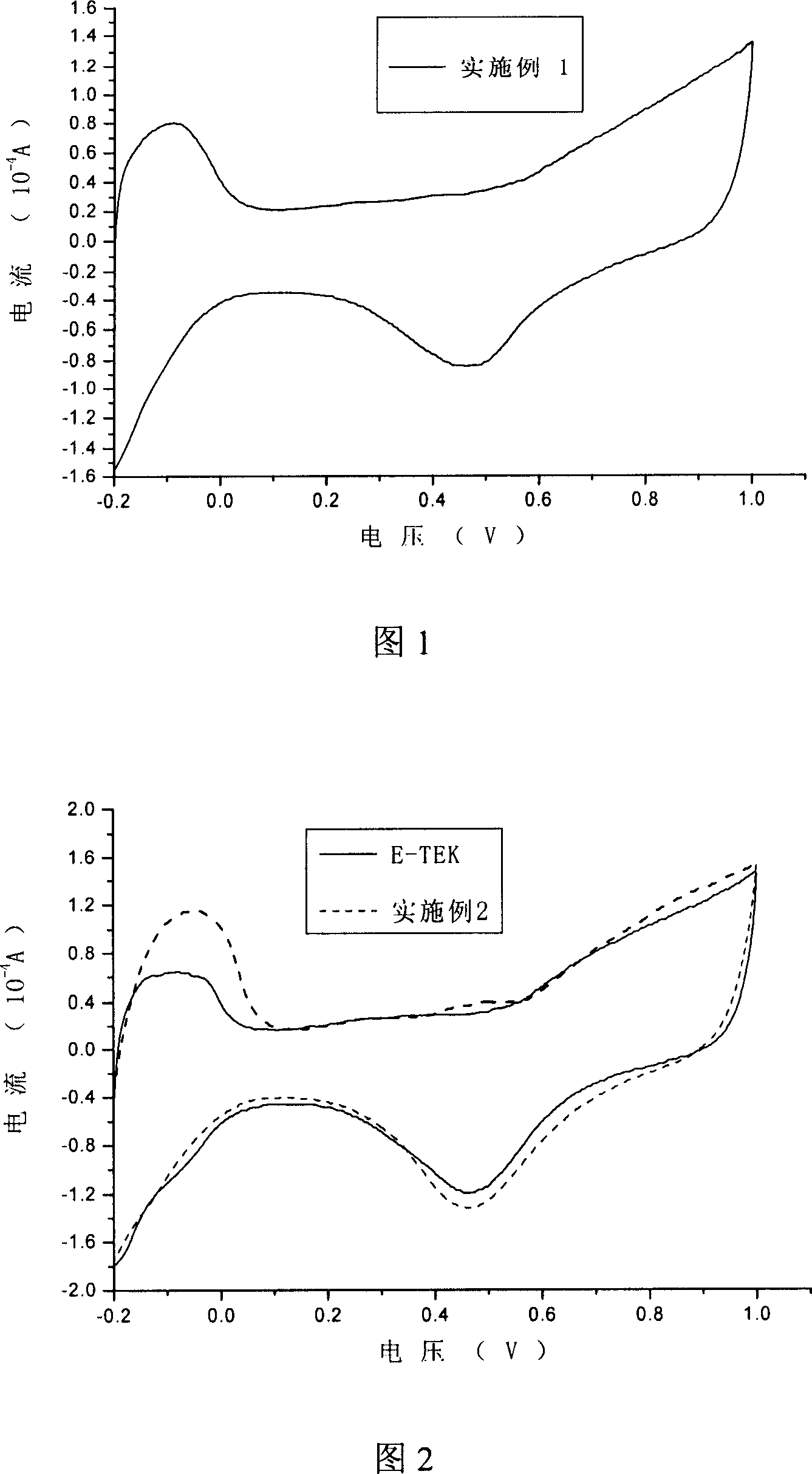

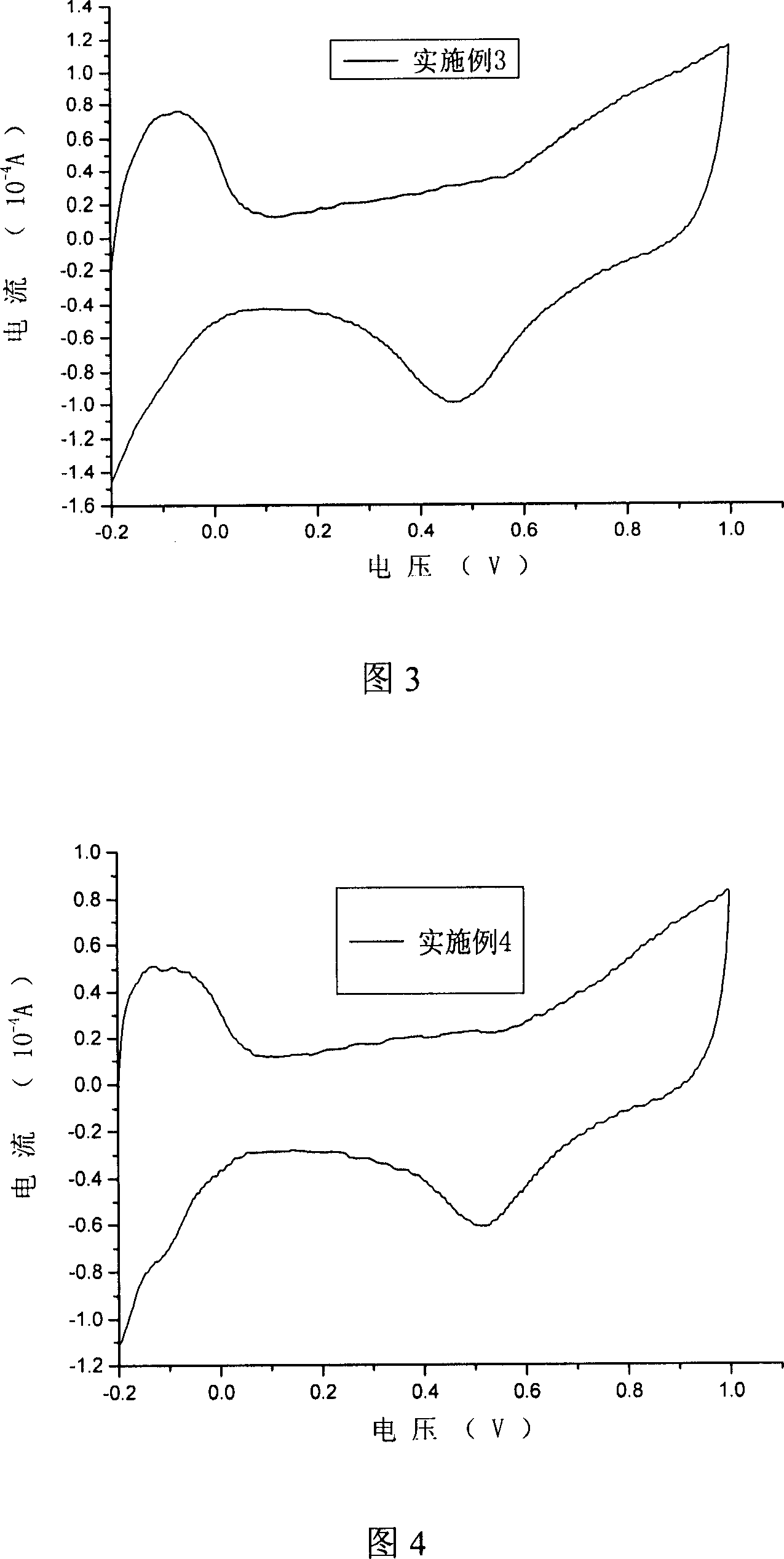

Embodiment 1

[0043] This example is used to illustrate the preparation of the catalyst provided by the present invention.

[0044] First grind the VXC-72 activated carbon for 1 hour, then place the carbon black in a muffle furnace and sinter at 200°C for 4 hours under an inert gas atmosphere, then grind for 1 hour, and pass through a 800-mesh sieve.

[0045] Disperse 0.1 g of carbon black powder in 40 mL of isopropanol by ultrasonication at 40 kHz for 5 min, then transfer to a mixture of 20 mL of ethylene glycol and 0.1 g of tartaric acid at 120 rpm Stir for 4 hours.

[0046]Add the aqueous solution of chloroplatinic acid with a concentration of 0.005 mol / L to the ethylene glycol in which carbon black is dispersed, and continue stirring for 5 hours while controlling the reaction pH to 7 so that the carbon black can fully absorb chloroplatinic acid to obtain a suspension. Wherein, the consumption of the chloroplatinic acid aqueous solution is such that the weight ratio of platinum containe...

Embodiment 2

[0050] This example is used to illustrate the preparation of the catalyst provided by the present invention.

[0051] First grind the VXC-72 activated carbon for 3 hours, then place the carbon black in a muffle furnace and sinter at 700°C for 5 hours under an inert gas atmosphere, then grind for 3 hours, and pass through a 800-mesh sieve.

[0052] By ultrasonication at 50 kHz for 30 min, 0.12 g of carbon black powder was dispersed in 40 mL of isopropanol, then transferred to a mixture of 25 mL of ethylene glycol, 0.1 g of tartaric acid, and 0.1 g of malic acid, and dissolved at 100 Stirring was continued at a speed of rpm for 1 hour.

[0053] Add the aqueous solution of chloroplatinic acid with a concentration of 0.02 mol / L to the ethylene glycol in which carbon black is dispersed, and continue stirring for 3 hours while controlling the reaction pH to 8 so that the carbon black can fully absorb chloroplatinic acid to obtain a suspension. Wherein, the consumption of the chloro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com