Bearing of motor driven fuel pump

A fuel pump and motor-type technology, applied in the field of motor-type fuel pump bearings, can solve the problems of accelerated wear process and lack of wear resistance, and achieve good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

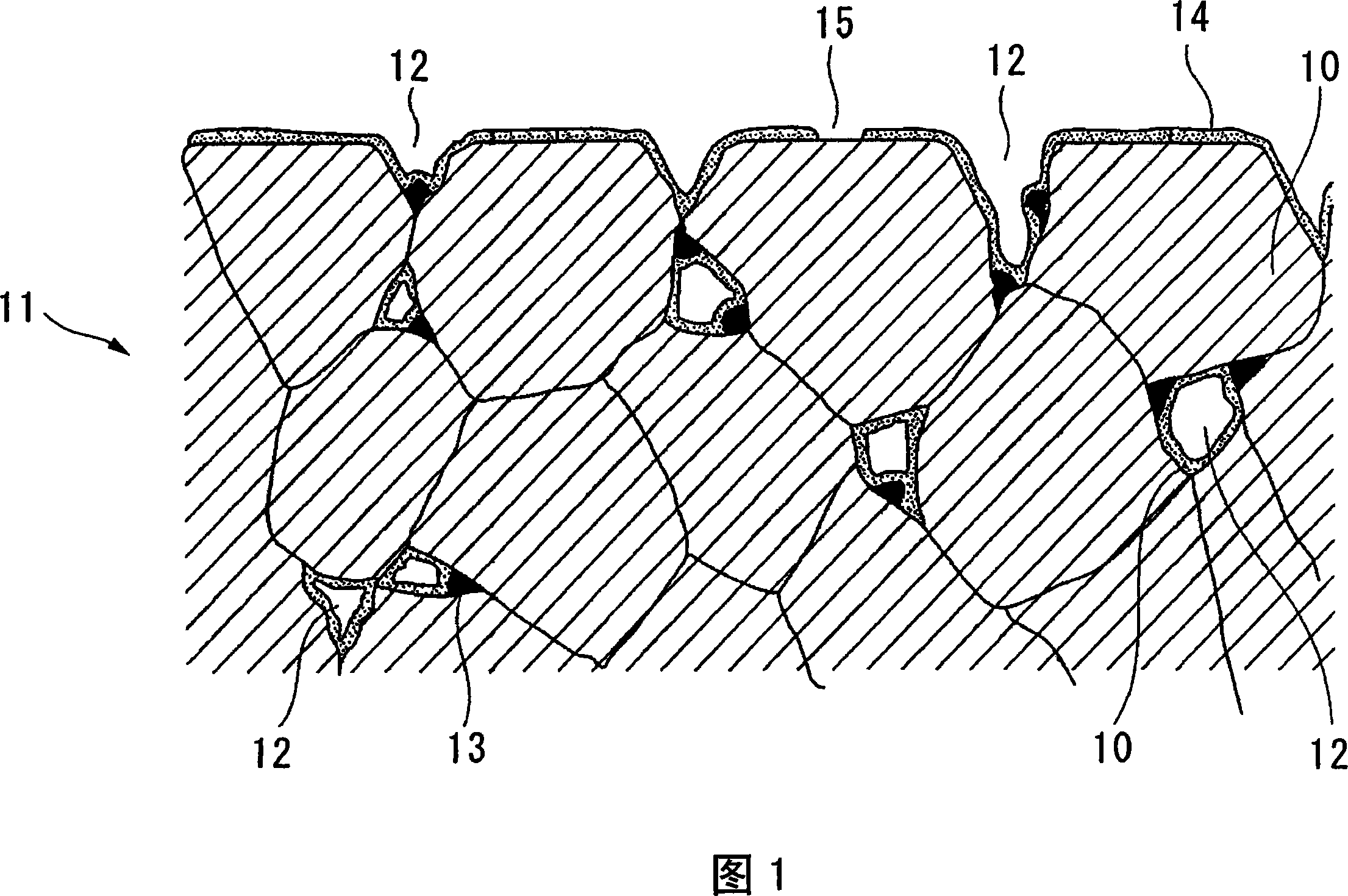

[0024] Next, the bearing of the present invention will be described with reference to FIG. 1 . FIG. 1 is a schematic diagram of a cross-sectional structure observed when a surface cut at a surface passing through the central axis of the bearing is observed with an optical microscope on the surface portion of the bearing. In this bearing, open pores 12 having a porosity of 8 to 18% are distributed in a bearing matrix 11 made of Cu—Ni alloy grains 10 . In addition, the P component is distributed in the grain boundaries of the Cu—Ni alloy particles 10 , and the free graphite 13 is distributed along the inner surfaces of the open pores 12 . If such a Cu—Ni based sintered alloy is used to constitute a bearing, good wear resistance can be ensured by the Cu—Ni alloy grains 10 constituting the base 11 . In addition, based on the effect of the highly lubricating free graphite 13 free on the inner surface of the air hole 12 and the fluid lubrication film formed by the liquid fuel suppl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com