Efficient micro-machining apparatus and method employing multiple laser beams

A laser beam and beam technology, applied in the field of lasers, can solve problems such as poor focusing of laser beams, and achieve the effects of increasing output, increasing system costs, and minimizing distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

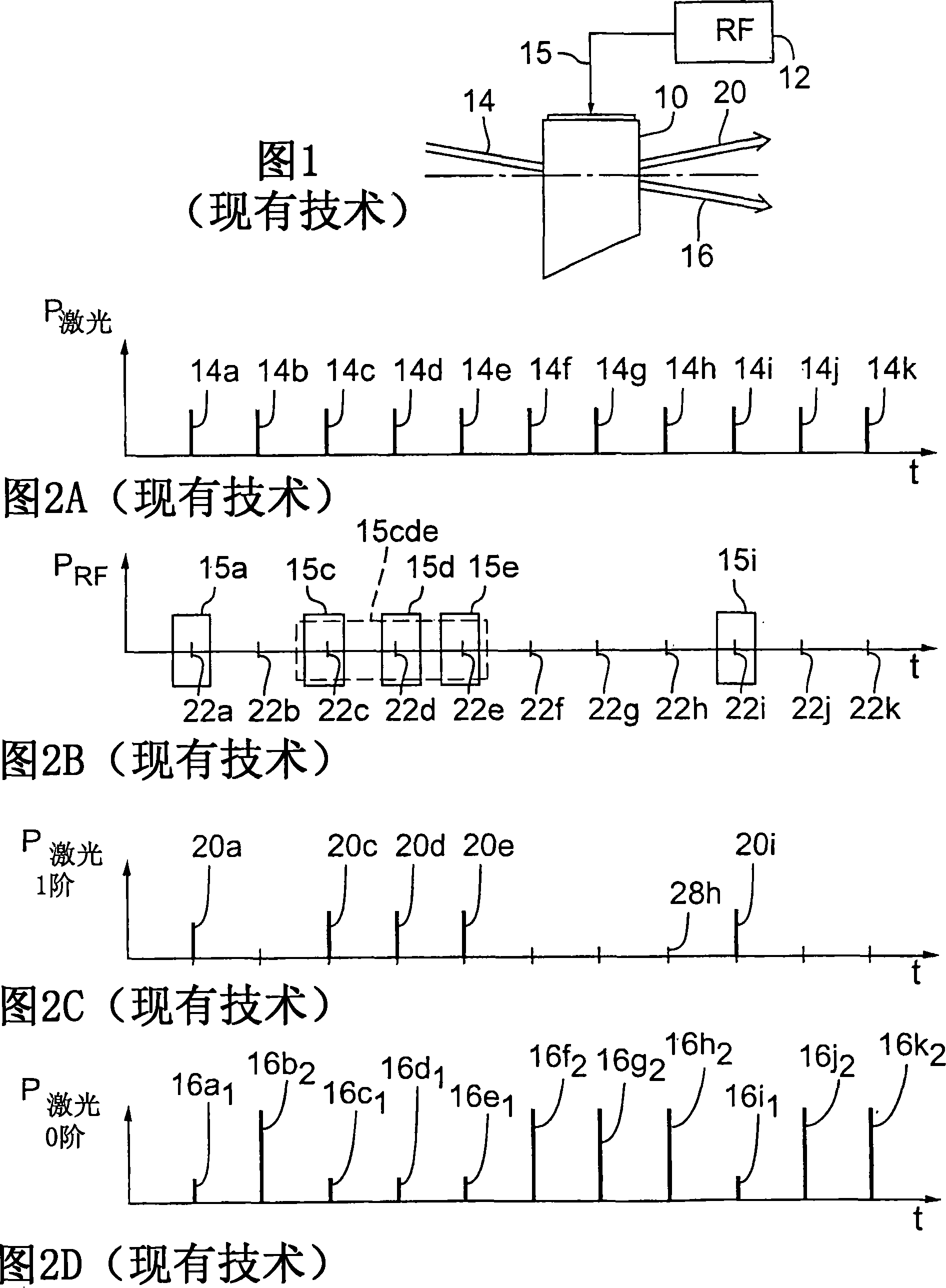

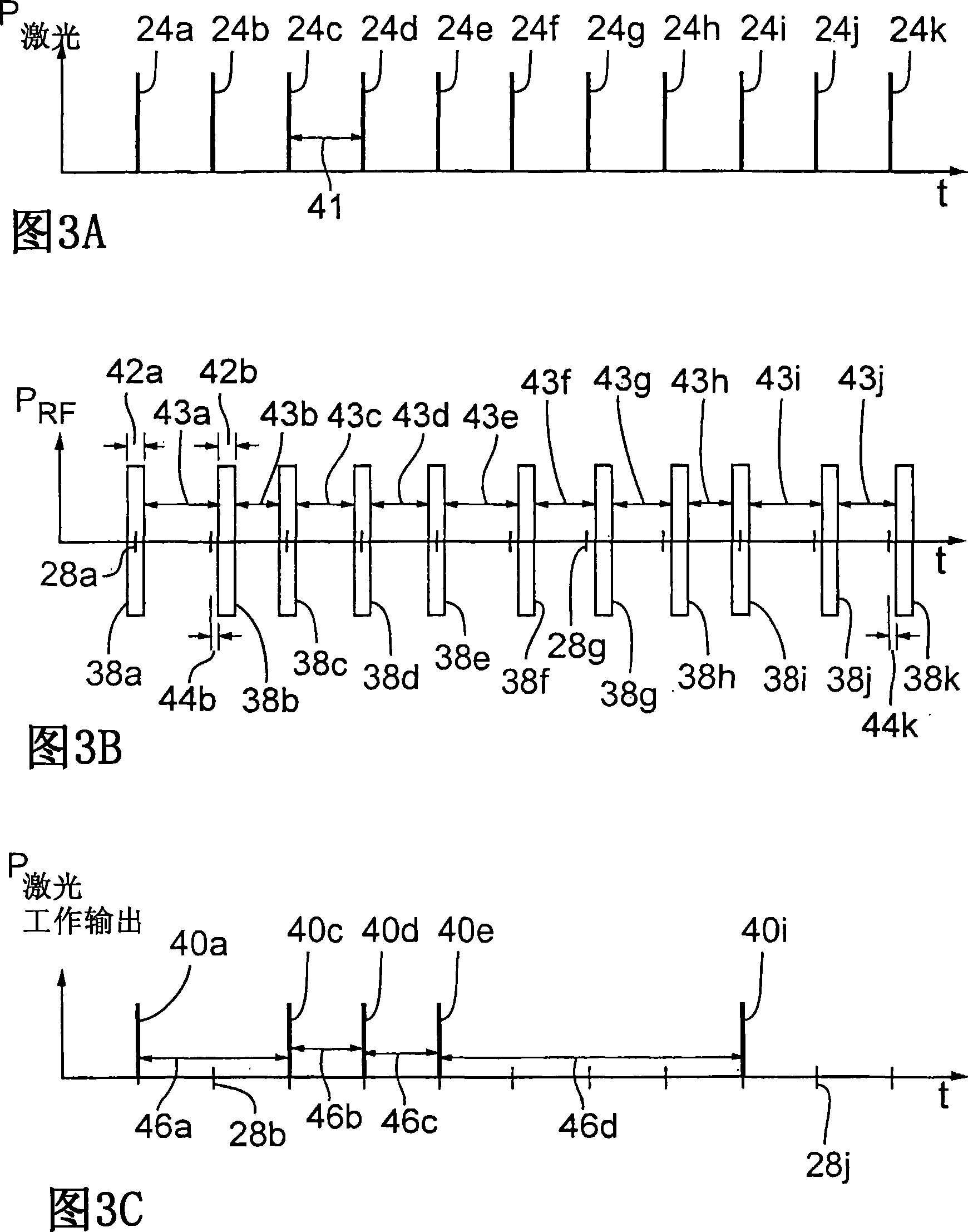

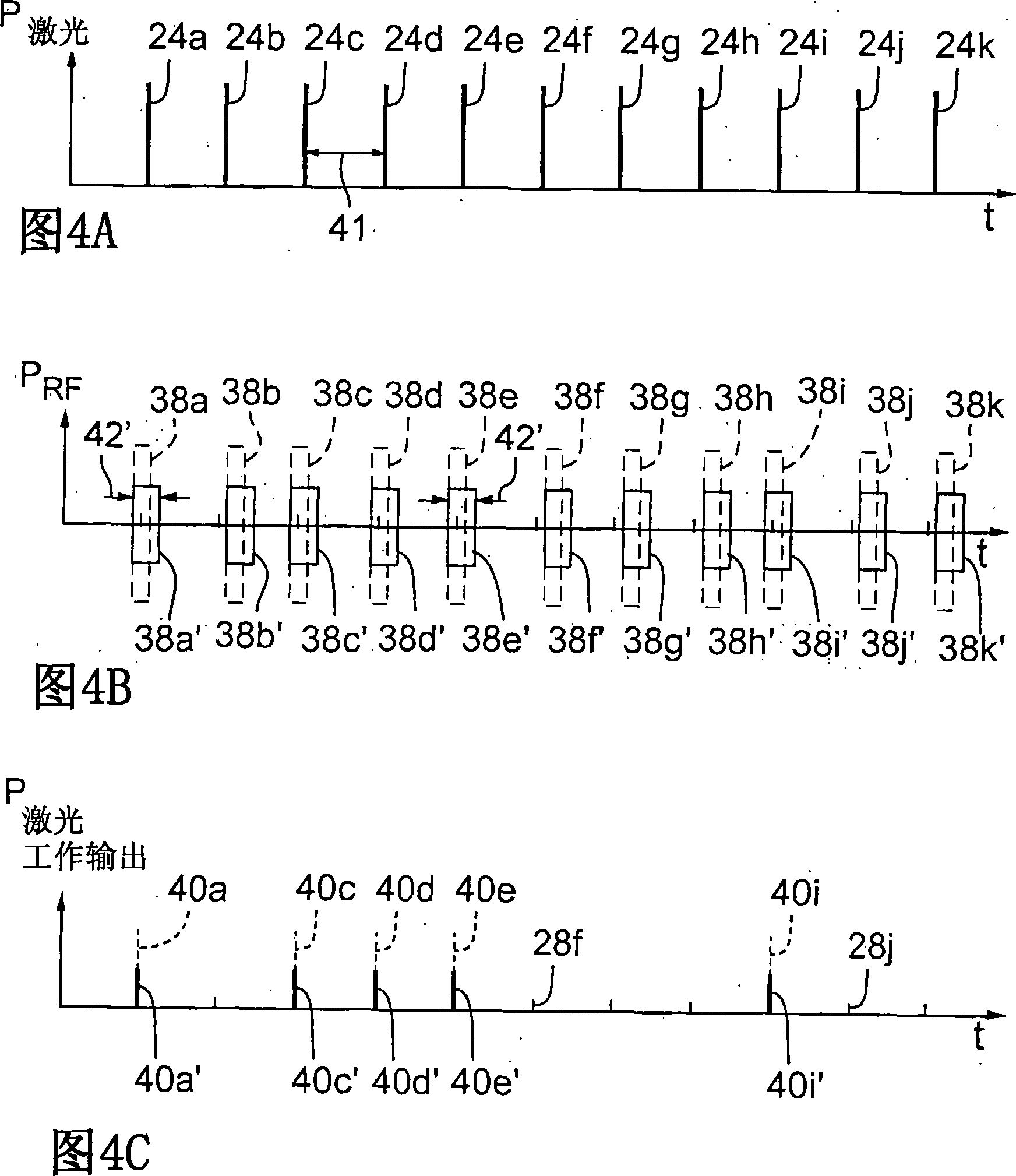

[0043] [0042] By employing the pulse picking and laser power control methods shown with reference to FIGS. 3A-3C and 4A-4C, respectively, thermal load variations in an AOM, such as prior art AOM 10, can be reduced. 3A-3C (collectively FIG. 3 ) illustrate laser outputs 24a-24k (collectively laser outputs 24), RF pulses 38a-38k (collectively RF pulses 38) and working laser outputs applied to prior art AOM 10. Respective timing diagrams of 40a, 40c, 40d, 40e, and 40i (collectively referred to as working laser output 40). Specifically, FIG. 3A shows laser outputs 24a-24k emitted by a laser (not shown) at a fixed repetition rate and separated by substantially equal laser output intervals 41 . In typical embodiments, the laser output repetition rate may range from about 1 KHz to about 500 KHz. Exemplary laser output repetition rates range from about 25 KHz to greater than about 100 KHz. For link processing embodiments, each working laser output 40 preferably includes a single lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com