Phase change memory unit with loop phase change material and its making method

A technology of phase-change memory and phase-change materials, which is applied in the field of micro-nano electronics and can solve problems such as differences in device structure preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

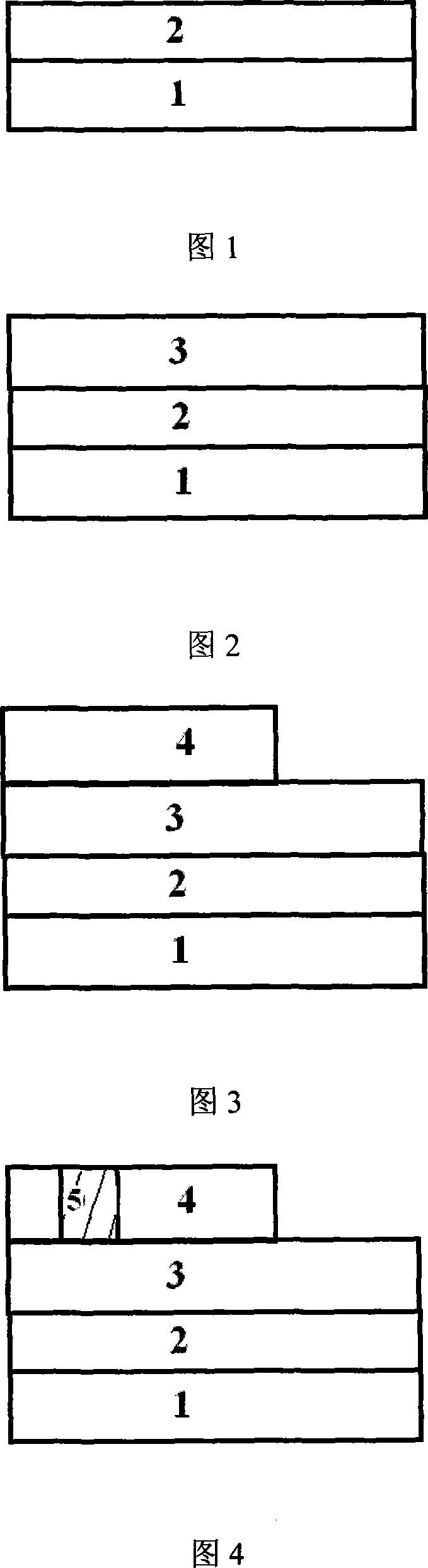

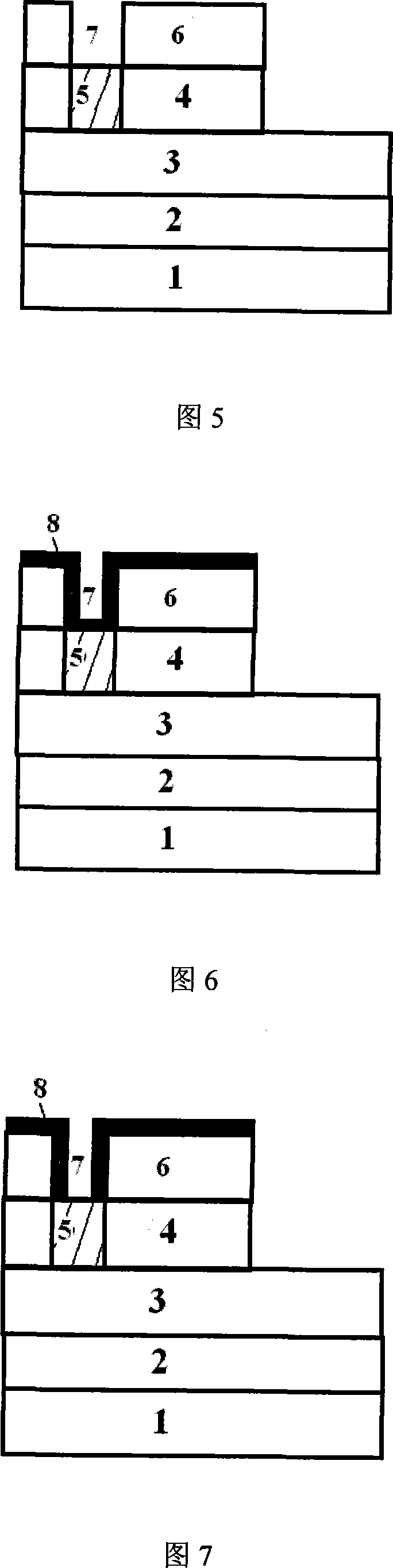

[0043] The preparation process of the phase change memory device unit prepared by utilizing the annular phase change material according to the present invention is as follows:

[0044] Step 1: The substrate is a silicon wafer, and a layer of SiO is prepared on the silicon wafer by thermal oxidation 2 The first insulating material layer has a film thickness of 500nm. (figure 1)

[0045] Step 2: On SiO 2 On the first insulating material layer, the lower electrode W thin film is prepared by magnetron sputtering method, and the process parameters are: the background pressure is 1×10 -4 Pa, the Ar gas pressure during sputtering is 0.08Pa, the sputtering power is 400W, the substrate temperature is 25°C, and the film thickness is 100nm. (figure 2)

[0046] Step 3: Prepare SiO on W film by magnetron sputtering 2 For the second insulating film layer, the process parameters are: the background air pressure is 1×10 -4 Pa, the Ar gas pressure during sputtering is 0.12Pa, the sputter...

Embodiment 2

[0056] Change step 5 in embodiment 1 as follows: in SiO 2 Preparation of heat insulating material SiO by PECVD method on heat insulating film and TiN heating electrode material 2 Thin film, the thickness of the film is 200nm; then, conventional photolithography technology is used to expose and etch directly above the heating electrode TiN to prepare a circular hole with a diameter of 200nm, and the heating electrode TiN is exposed in the hole.

[0057] Change step 7 in Example 1 to the following: Reactive ion etching technology is used to etch and remove the phase change material at the bottom of the circular hole to form a ring-shaped phase change material with an outer diameter of 200 nm and a wall thickness of 10 nm.

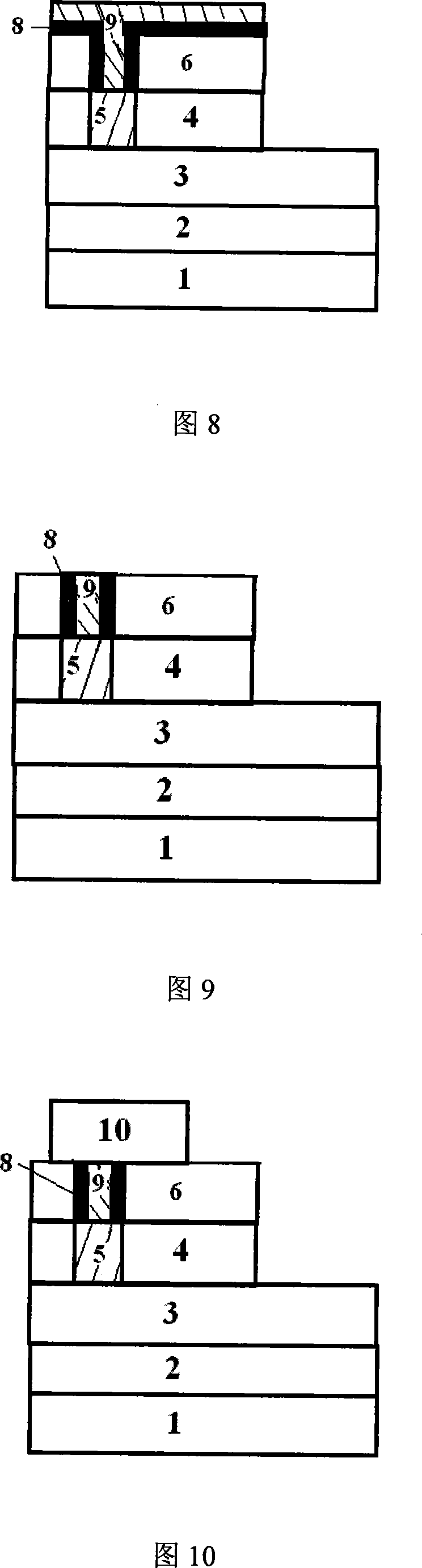

[0058] The rest of the steps are exactly the same as in Example 1, and a phase change memory device unit whose outer diameter of the annular phase change material is smaller than that of the heating electrode material can be prepared. (Figure 11)

Embodiment 3

[0060] Change step 5 in embodiment 1 as follows: in SiO 2 Preparation of heat insulating material SiO by PECVD method on heat insulating film and TiN heating electrode material 2 Thin film, the thickness of the film is 200nm; then, conventional photolithography technology is used to expose and etch directly above the heating electrode TiN to prepare a circular hole with a diameter of 350nm, and the heating electrode TiN is exposed in the hole.

[0061] Change step 6 in embodiment 1 as follows: adopt atomic layer deposition technology to prepare Ge in the hole 2 Sb 2 Te 5 Phase change material with a film thickness of 40nm.

[0062] Change step 7 in Example 1 to the following: Reactive ion etching technology is used to etch and remove the phase-change material at the bottom of the circular hole to form a ring-shaped phase-change material with an outer diameter of 350 nm and a wall thickness of 40 nm.

[0063] The rest of the steps are exactly the same as in Example 1, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com