Hard alloy added with boron element and preparation method thereof

A technology of cemented carbide and elements, which is applied in the field of cemented carbide and its preparation, can solve the problems of difficult control of the degree of reaction, unfavorable diffusion and uniform distribution of boron elements, and deterioration of alloy performance, and achieve low production cost, improved toughness, and inhibition The effect of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

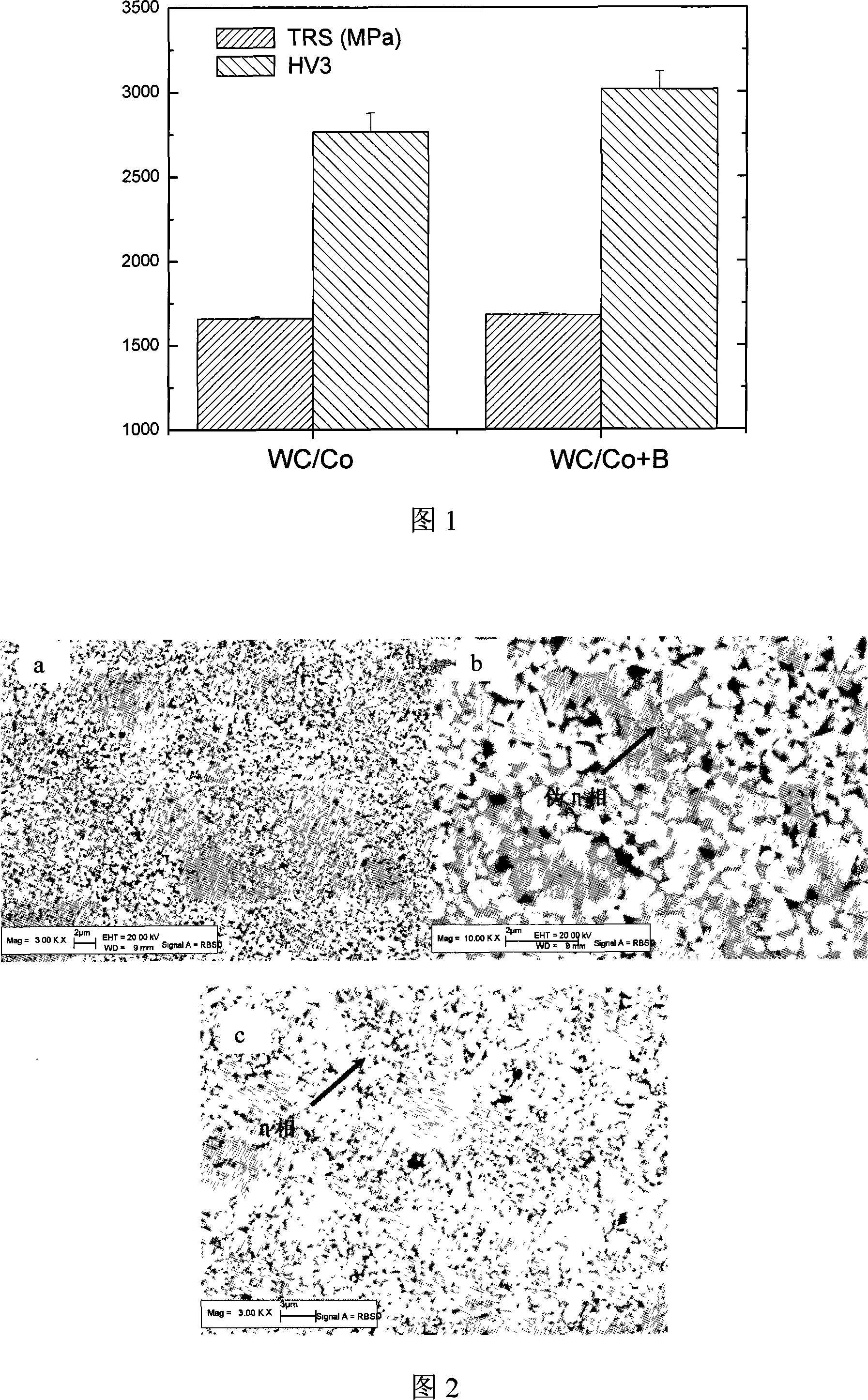

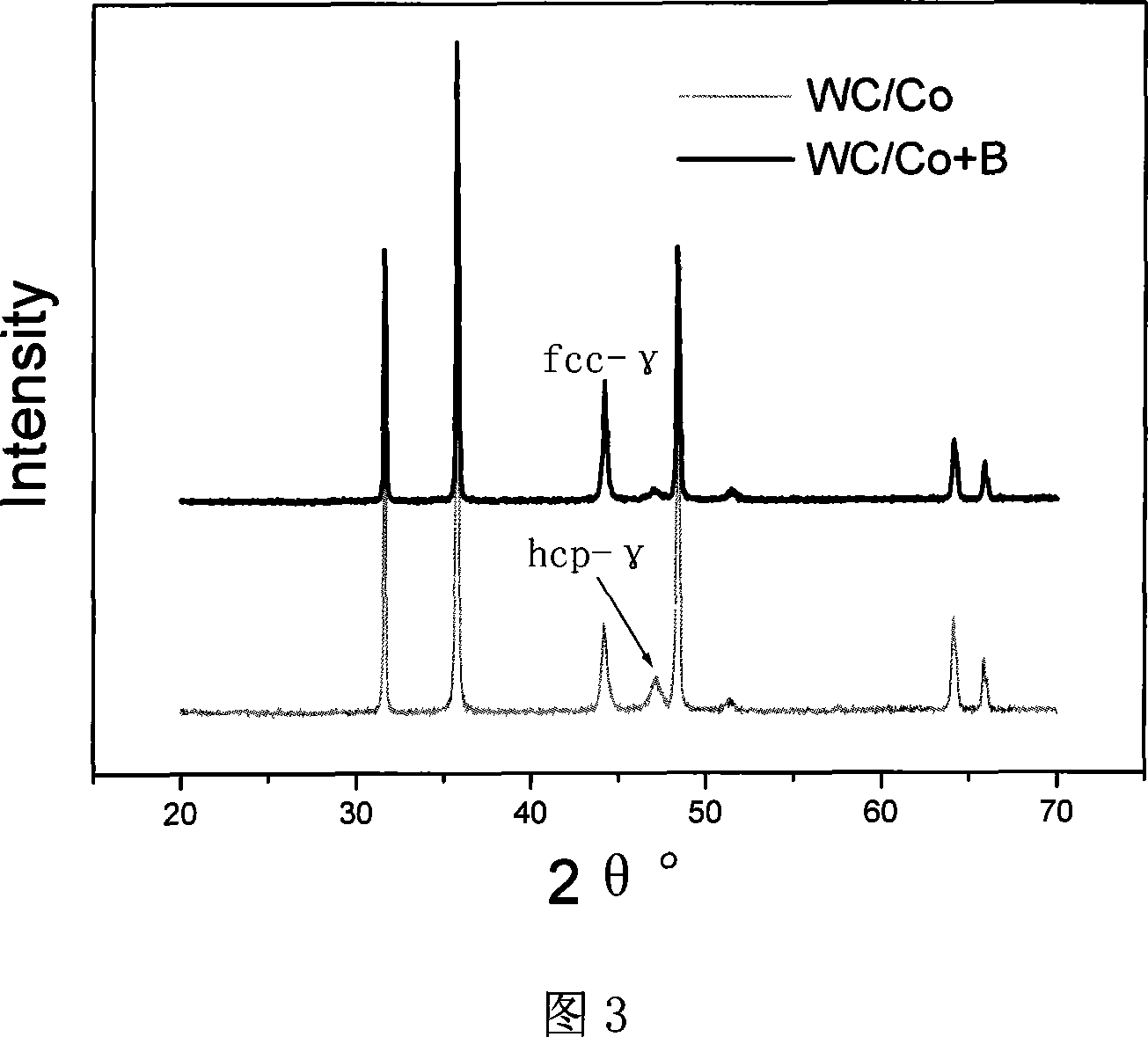

[0011] Embodiment 1: adopt hard phase WC, bonding phase Co, its particle size is respectively 0.8 μ m, 1.0 μ m (the same below), and the B powder of 4 μ m is added in batching, makes the content of WC, Co, B in the raw material be 89.99% respectively , 10%, 0.01%, wherein the mass percentage of B element and Co is 0.1%. A total of 1Kg of the above powder was batched and uniformly mixed, ball-milled with 400ml of alcohol for 60-65 hours, and then spray-dried, pressed and sintered to obtain a boron-containing cemented carbide with a strength of 3103MPa and a hardness of HV 3 1680, fracture toughness K IC =10.3Mpm -1 / 2 . Its microstructure is shown in Figure 2.

Embodiment 2

[0014] Embodiment 2: adopt hard phase WC, bonding phase Co, batching adds the B powder of 4 μ m, make the content of WC, Co, B in the raw material be respectively 89.7%, 10%, 0.03%, wherein the mass of B element and Co The percentage is 0.3%. A total of 1Kg of the above powder was batched and uniformly mixed, ball-milled with 400ml of alcohol for 60-65 hours, and then spray-dried, pressed and sintered to obtain a boron-containing cemented carbide with a strength of 2970MPa and a hardness of HV 3 1680,K IC =10.2Mpm -1 / 2 .

Embodiment 3

[0017] Embodiment 3: adopt hard phase WC and TaC, binding phase Co, content is respectively 92.5%, 6.5% and 1.0%, the B powder that batching adds 4 μm makes hard phase, Co, B content respectively in the raw material 92.5%, 6.5%, 0.005%, wherein the mass percentage of B element and Co is 0.0769%. A total of 1Kg of the above powder was batched and uniformly mixed, ball-milled with 380ml of alcohol for 27-35 hours, and then spray-dried, pressed and sintered to obtain a boron-containing cemented carbide with a strength of 2200MPa and a hardness of HV 3 1610, K IC =10.3Mpm -1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com