Repair method of soldering part and device thereof

A technology for parts and welding torches, applied in the field of repairing and installation of welded parts, can solve the problems of scrapped parts, damage to the body metal, low efficiency of manual grinding, etc., and achieve the effects of less heat generation, wider heat-affected zone, and improved success rate of repairing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

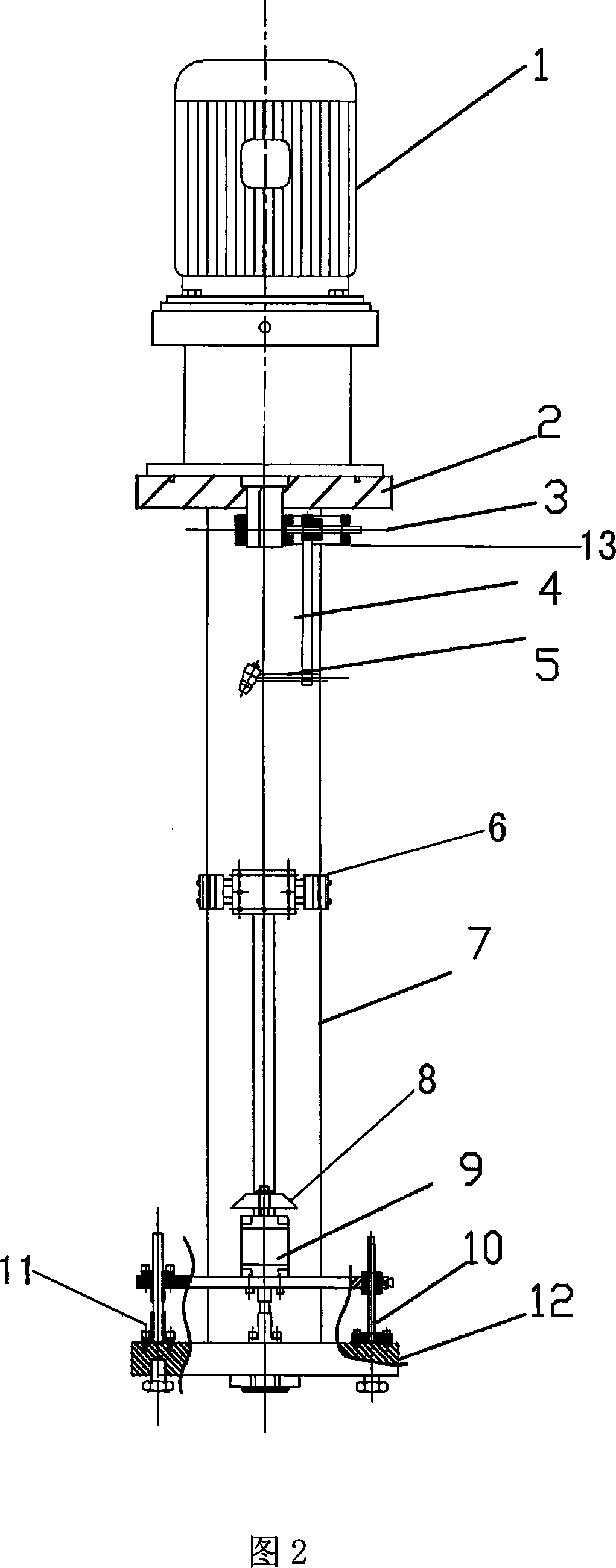

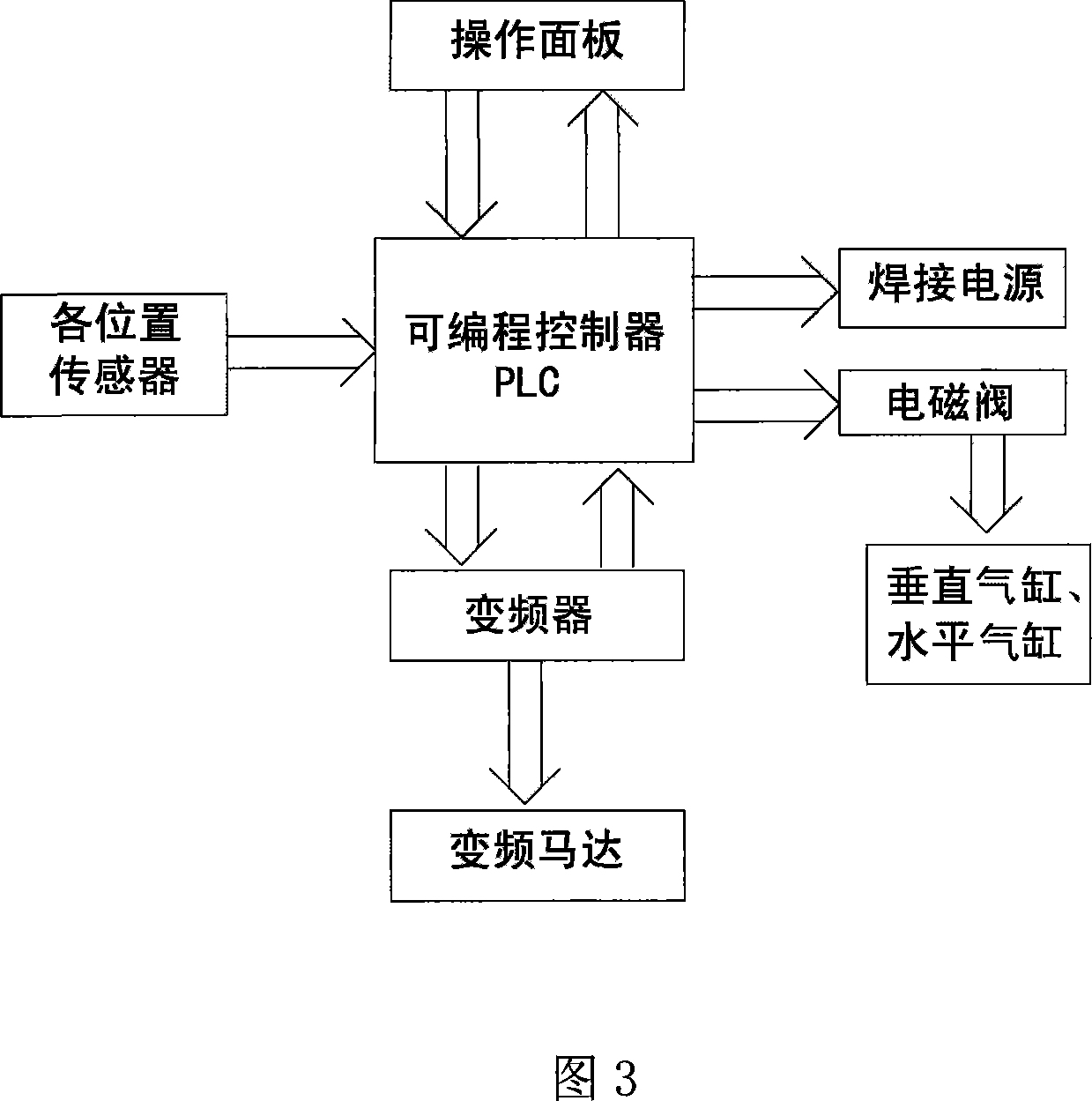

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0028] The following is an example to illustrate the present invention for the rework of the Strut automobile shock absorber.

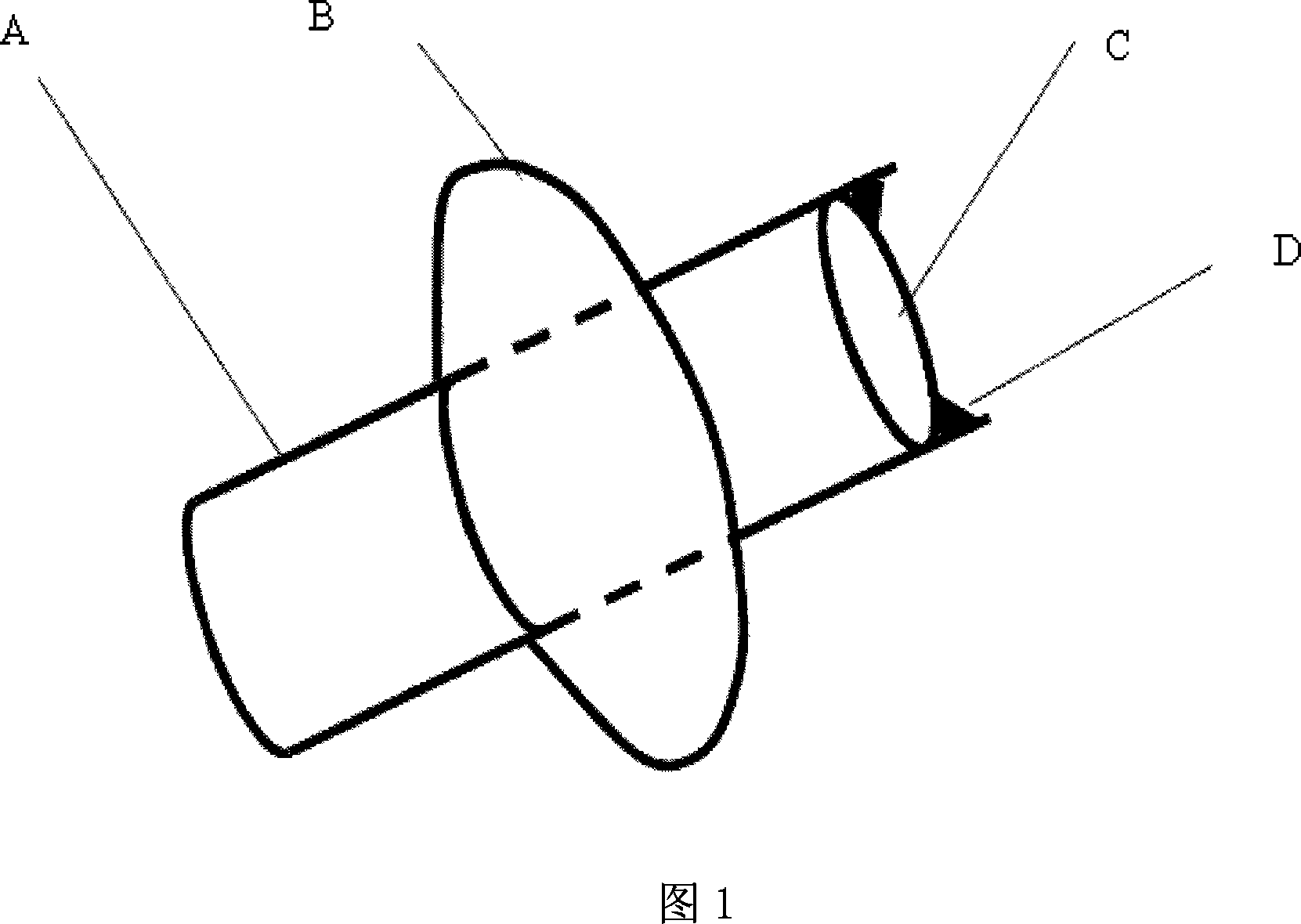

[0029] The welding assembly of Strut automobile shock absorber is shown in attached drawing 1. It is mainly composed of liquid storage cylinder A, spring plate B, bottom cover C, ear pieces (not shown in the figure), etc. The annular angle between the liquid storage cylinder and the bottom cover is Weld D is difficult with CO 2 Arc method repair, a little careless, then the height of the annular weld exceeds the metal of the liquid storage cylinder body and is scrapped.

[0030] Considering that the scrapping of the Strut shock absorber product assembly is mostly due to unrepaired air holes or incomplete fusion at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com