Control method for epitaxial layer transition zone on re-mixed arsenic underlay

A control method and epitaxial layer technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as difficulty in control, deterioration of forward characteristics, poor controllability of resistivity uniformity, etc. Low efficiency, increased resistivity gradient, good resistivity uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with the specific embodiment of the present invention, the present invention will be described in further detail:

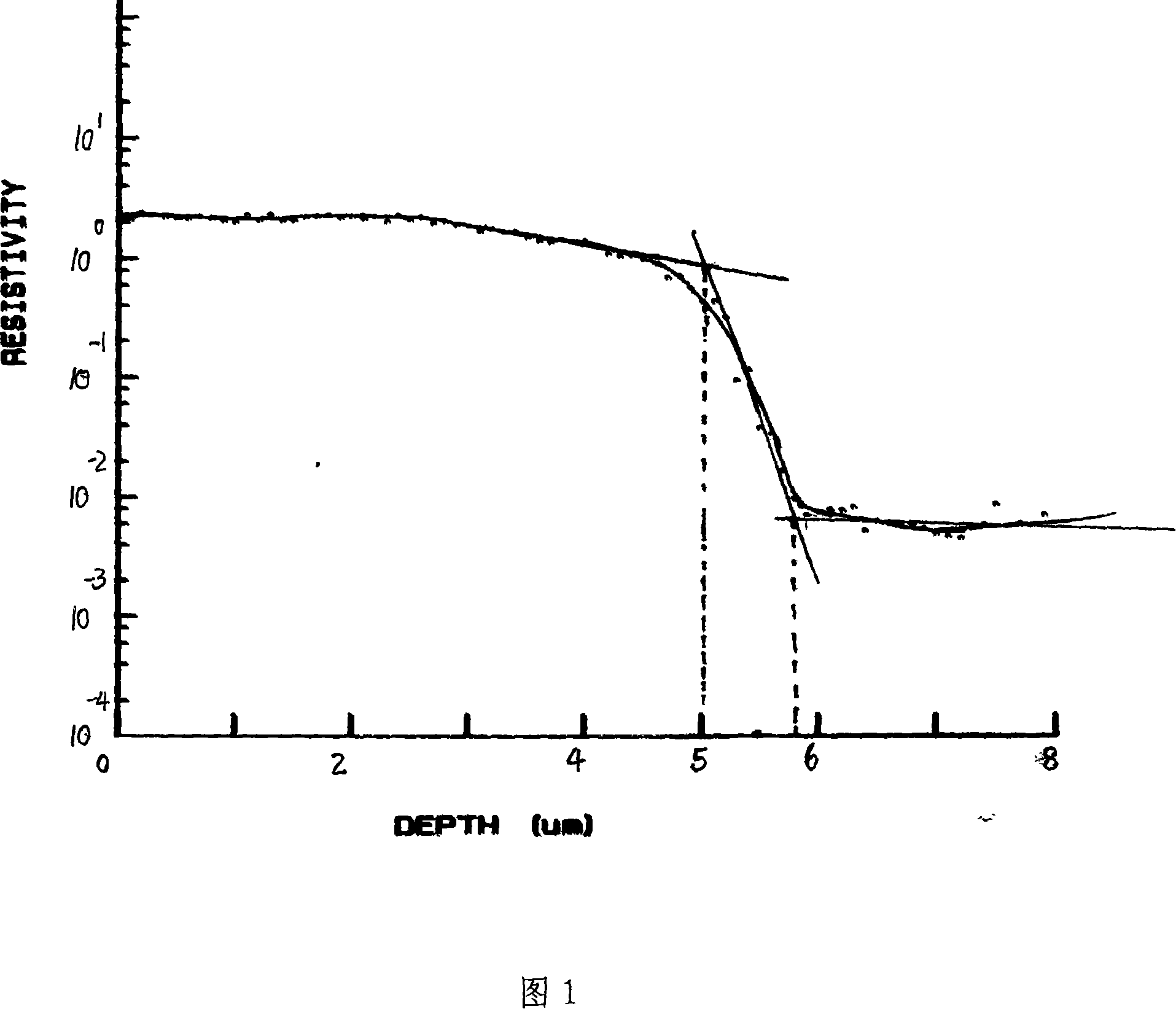

[0046] In the embodiment of the present invention, the measurement and calculation method of the transition zone is as follows: after the sample is ground, the extension resistance analyzer is used to measure the thickness of the epitaxial layer and the longitudinal distribution curve of the resistivity concentration, and then the cross tangent method is used to obtain The thickness of the transition zone, the specific algorithm is shown in Figure 1.

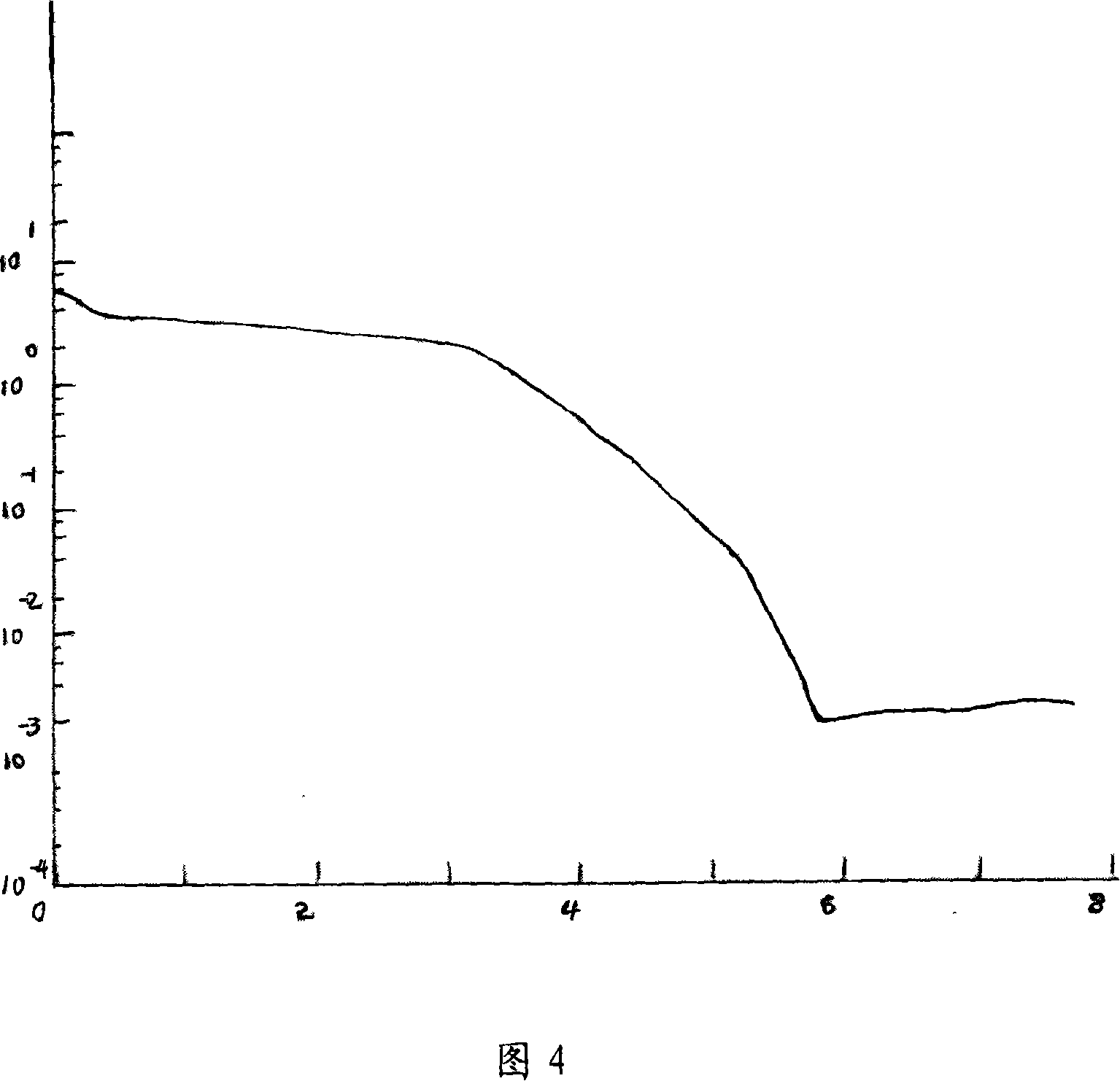

[0047] In this embodiment, the method shown in the present invention is compared with the conventional "two-step epitaxy method". In the two epitaxy methods of the present invention, the specific growth conditions of silicon epitaxy are:

[0048] A main H 2 Flow rate: 100SLM.

[0049] B loading and unloading temperature is 870°C,

[0050] C hydrogen baking temperature is 1160°C,

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com